Ink-jet printer

A technology of inkjet printers and printing media, applied to printing devices, printing, transfer materials, etc., can solve problems such as easy wrinkles, obvious defects, and paper swelling, so as to avoid wrinkles or bulging, rich and vivid colors, and avoid cost-wasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

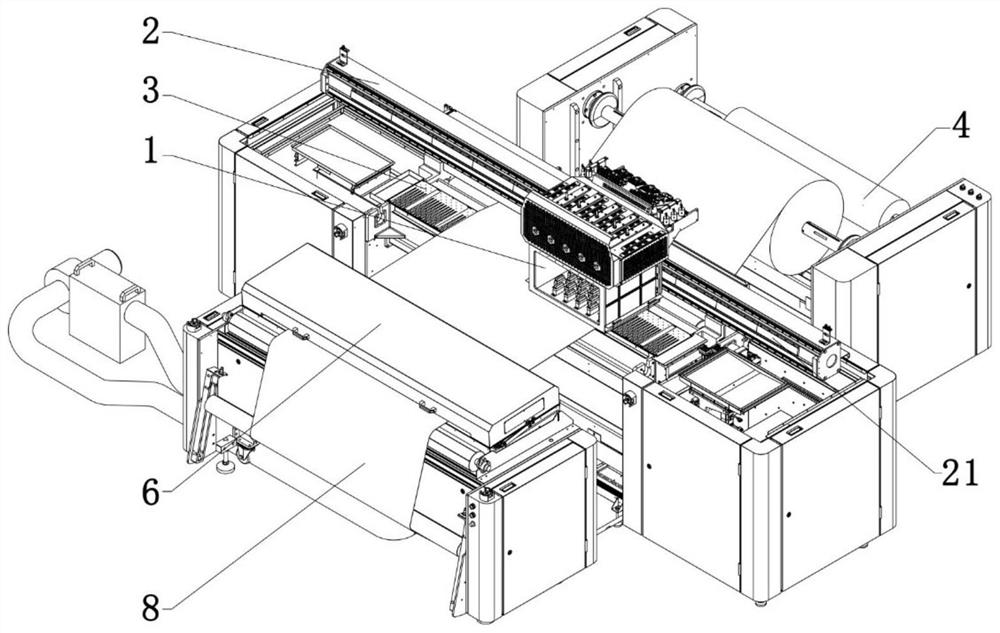

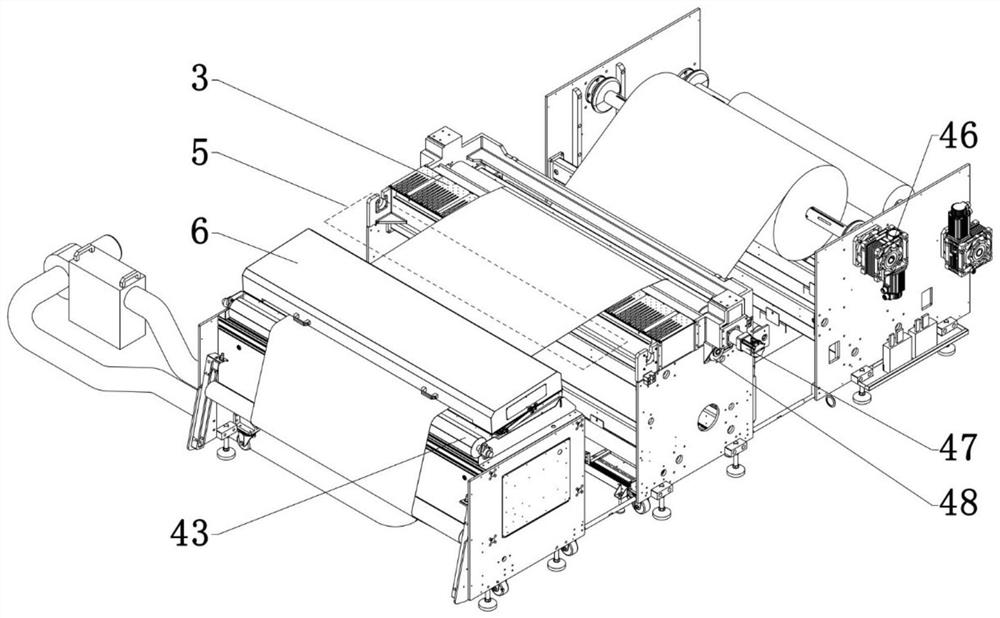

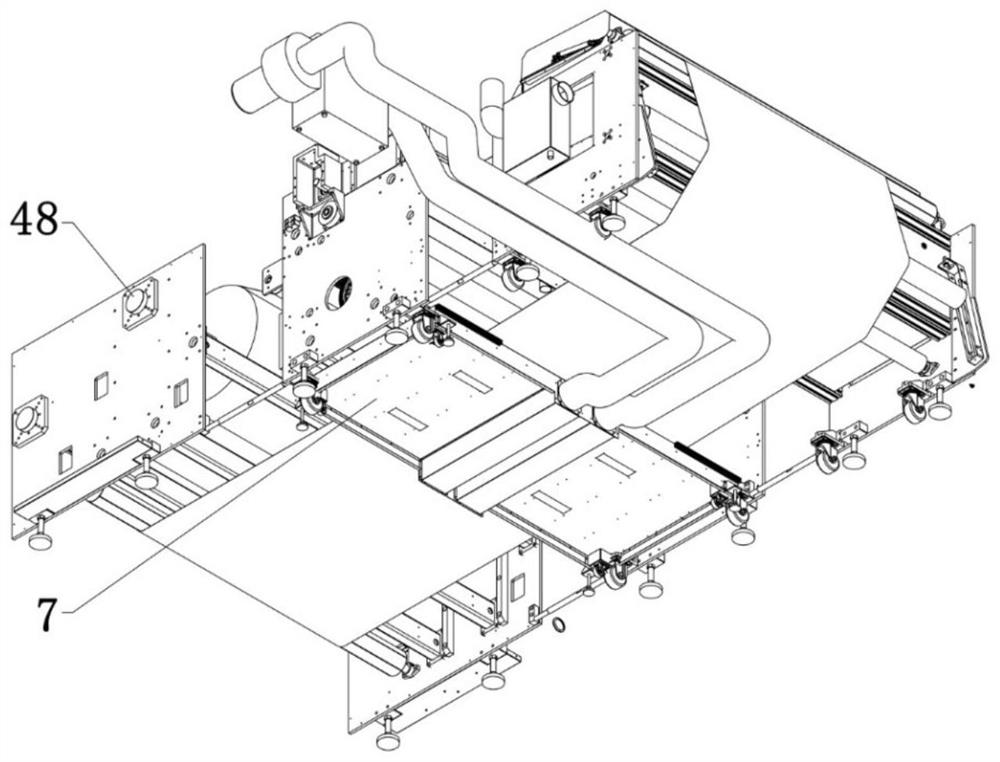

[0051] refer to Figure 1 to Figure 3 , Figure 9 As shown, an inkjet printer is improved in that it includes a printing carriage 1, a driving mechanism 2, a printing platform 3, a feeding mechanism 4, a drying device 6 and an air drying device 7, and the feeding mechanism 4 includes a The first feeding mechanism on the front side, the second feeding mechanism in the middle, and the third feeding mechanism on the rear side, the feeding mechanism 4 is used to carry the printing medium 8 and move the printing medium 8 in the longitudinal direction, so The printing platform 3 is installed above the second feeding structure, the driving mechanism 2 is horizontally erected above the second feeding mechanism, the printing carriage 1 is installed on the driving mechanism 2, and the The printing carriage 1 is located in the upper area of the printing platform 3; the drying device 6 is installed above the first feeding mechanism, and is used for drying the printing medium 8, so as t...

Embodiment 2

[0064] On the basis of Example 1, refer to Figure 4 As shown, the printing carriage 1 includes a degassing and circulating device, and the degassing and circulating device includes a secondary ink cartridge 11, and the secondary ink cartridge 11 is respectively connected with the main ink tank and the print head for continuous supply to the print head. Ink, one side of the secondary ink cartridge 11 is serially connected with an ink pump 12, a filter 13 and a degassing device 14, and the other end of the degassing device 14 is communicated with the other side of the secondary ink cartridge 11 , the ink pump 12 is used to provide power for the flow of ink, the filter 13 is used to filter impurities in the ink, the degassing device 14 is used to remove the air in the ink, and the ink in the secondary ink cartridge 11 Driven by the ink pump 12, it flows through the filter 13 and the degassing device 14 in sequence, and then returns to the ink chamber of the secondary ink cartrid...

Embodiment 3

[0071] On the basis of Example 2, refer to Figure 5 to Figure 7 As shown, the secondary ink cartridge 11 includes an ink cartridge body 111 and an ink cartridge cover 112 that are covered with each other, the ink cartridge body 111 is provided with an ink chamber 1111, and the ink chamber 1111 is used for accommodating ink, and the ink cartridge body 111 A snap ring 1112 is provided at the upper end of the cartridge cover 1111 at the periphery of the ink chamber 1111 , and a sealing groove 1121 matching the snap ring 1112 is provided at the bottom of the ink cartridge cover 112 . The gap between the snap ring 1112 and the sealing groove 1121 in the sealing groove 1121 is filled with sealant, and the sealant is used to seal the ink cartridge body 111 and the ink cartridge cover 112 The connected position is sealed.

[0072] In this embodiment, during assembly, a certain amount of sealant is continuously and evenly filled in the sealing groove 1121 of the ink cartridge cover 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com