Brake

A brake and cylinder technology, applied in hydraulic brakes, brake actuators, gear shifting mechanisms, etc., can solve the problems of occupying the rhythm and unable to completely eliminate errors, and achieve the effect of reducing the braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

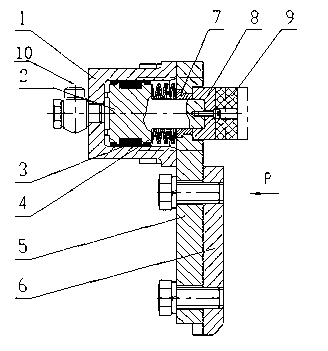

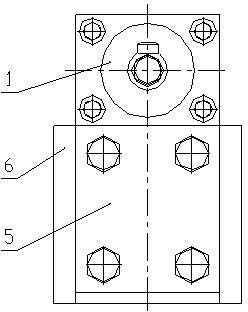

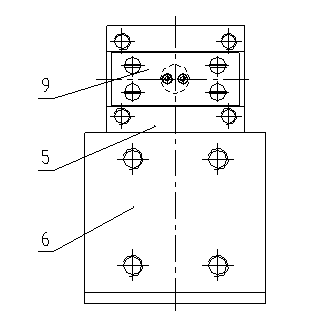

[0016] Such as figure 1 , 2 , 3, a brake is characterized in that: it at least includes a cylinder 1, a piston 2, a support plate 5, a bearing 6, a locking block 8, a brake pad 9, and the cylinder 1 is fixedly connected with the support plate 5, There is a piston 2 in the cylinder body 1, and the right end of the piston 2 is fitted in the guide sleeve 7, forming a piston cylinder with the cylinder body 1 and the support plate 5, the guide sleeve 7 is fixedly connected with the support plate 5, and the disc spring 4 is formed by the piston 2 and the support plate 5 In the cavity surrounded by the support plate 5, the locking block 8 is fixedly connected to the end of the piston 2, the brake pad 9 is glued to the locking block 8, the support 6 is fixedly connected to the support plate 5, and the cylinder body 1 is connected through the hole 10 hydraulic or pneumatic systems.

Embodiment 2

[0018] It is basically the same as Embodiment 1, the difference is that there is a notch at the contact between the support plate 5 and the locking block 8, which acts as a guide for the locking block 8 when the brake is working. The bearing 6 is welded at a suitable position of the tractor, and a notch is arranged on it to overcome the shear stress generated during braking. The brake pad 9 corresponds to the roller braking surface of the tractor, and the distance from the braking surface is 2mm. There is a seal 3 between the piston 2 and the cylinder 1 to prevent leakage of high-pressure oil or compressed air.

[0019] When braking, the hydraulic or pneumatic system controls the high-pressure oil or compressed air to enter from the hole 10. Under the action of the high-pressure oil or compressed air, the piston 2 protrudes outwards against the resistance of the disc spring 4, thereby pushing the brake pads 9 close. The braking surface of the roller table achieves the purpose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com