Equivalent-drop height powder impulse flowmeter

A technology of flowmeter and drop, applied in the field of dynamic measuring instruments for powder materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] The present invention is described in detail below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

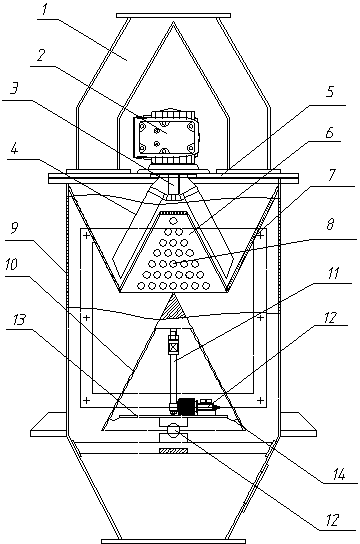

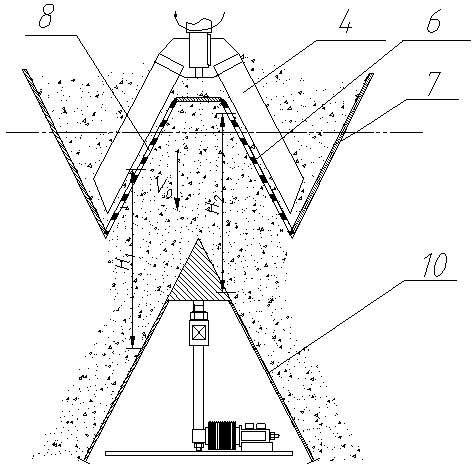

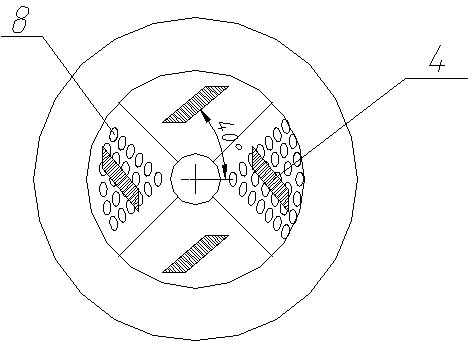

[0021] see figure 1 , on the upper part of a cylindrical shell 9, through the sealing flange 5, a material guide pipe 1 with a herringbone structure with one feed port and two discharge ports is installed. The top of the shell 9 is equipped with a deceleration Motor 2, the output shaft 3 of the geared motor 2 extends into the inside of the housing 9 from the center of the top of the housing 9, and the output shaft 3 is equipped with conical blades 4, thereby forming the multi-blade rotary feeder of the present invention.

[0022] Inside the cylindrical housing 9, an equal-fall drop feeder is installed below the feeder, which is composed of a drop chute 6 and a truncated cone cylinder 7 positioned in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com