Contact resistance measuring system and method based on voltage-frequency conversion method

A technology of contact resistance and frequency conversion, applied in measuring devices, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve the problems of poor data stability and low accuracy, and achieve high accuracy and strong data stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

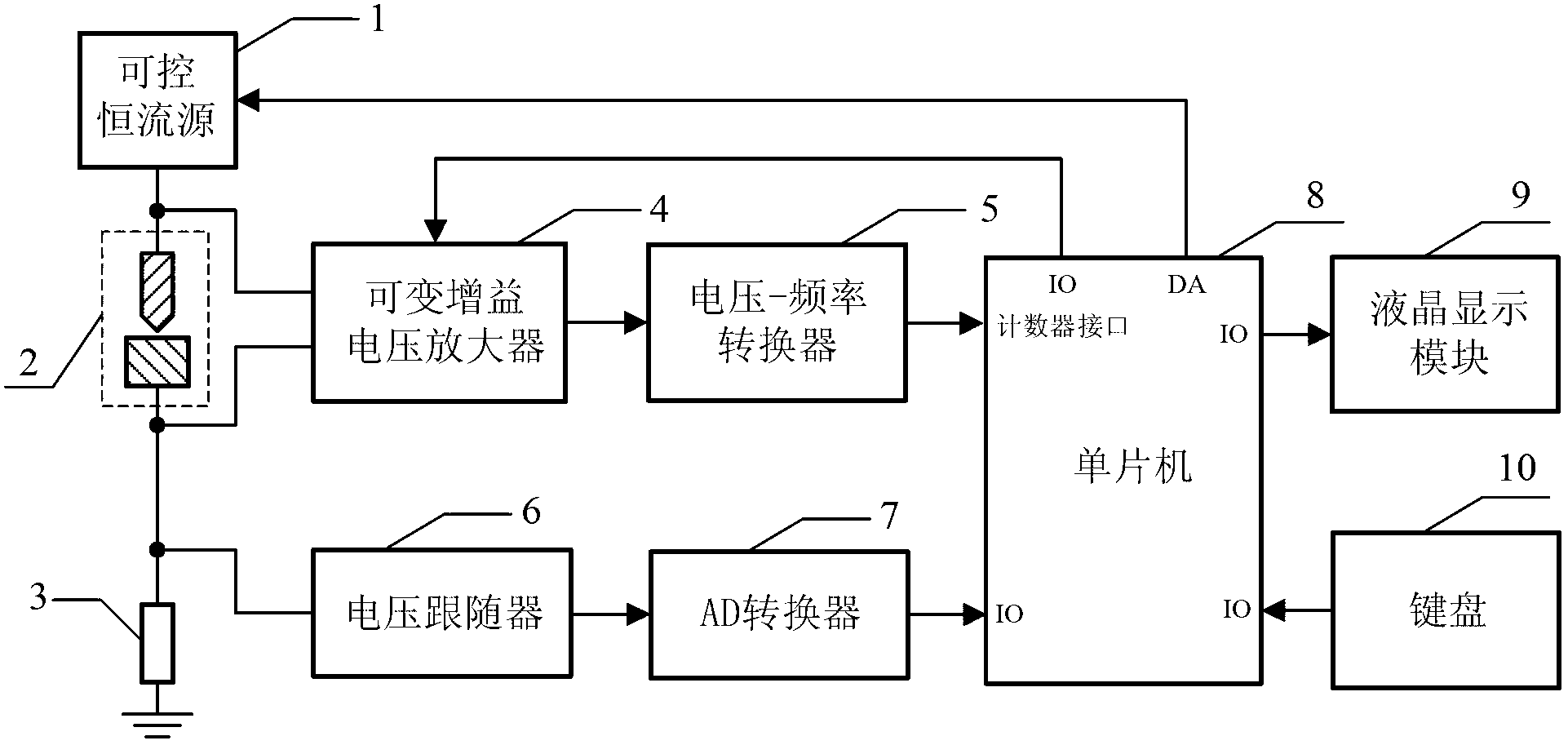

[0027] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, the contact resistance measurement system based on the voltage-frequency conversion method, which includes a controllable constant current source 1, a standard current-sensing resistor 3, a variable-gain voltage amplifier 4, a voltage-frequency converter 5, and a voltage follower 6. AD converter 7 and single chip microcomputer 8;

[0028] The power output terminal of the controllable current source 1 is connected to one end of the component under test 2; the other end of the component under test 2 is connected to one end of the standard current-sensing resistor 3; the other end of the standard current-sensing resistor 3 is connected to the power ground ;

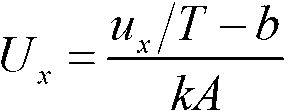

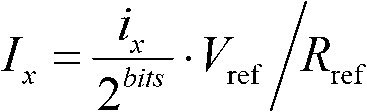

[0029] The variable gain voltage amplifier 4 collects the terminal voltage at both ends of the component under test 2; the voltage signal output terminal of the variable gain voltage amplifier 4 is connected with the voltage signa...

specific Embodiment approach 2

[0040] Embodiment 2. The contact resistance measurement system based on the voltage-frequency conversion method described in this embodiment and Embodiment 1 is characterized in that it also includes a liquid crystal display module 9, and the display signal input of the liquid crystal display module 9 The end is connected with the display signal output end of the single-chip microcomputer 8.

specific Embodiment approach 3

[0041] Specific embodiment three, this specific embodiment and the contact resistance measurement system based on the voltage-frequency conversion method described in specific embodiment one are characterized in that it also includes a keyboard 10, and the keyboard signal output terminal of the keyboard 10 is connected to the single-chip microcomputer 9 connected to the keyboard signal input terminal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com