A method for manufacturing a screen printing plate of a liquid crystal display sealing frame

A screen printing plate, liquid crystal display technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of reducing product quality, uneven box thickness, and increasing product manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

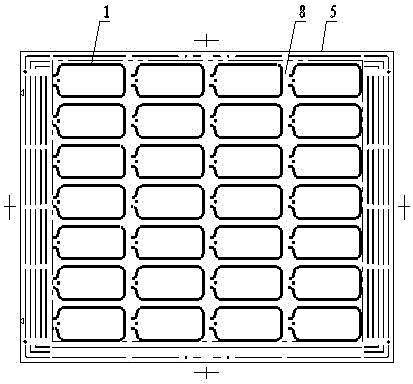

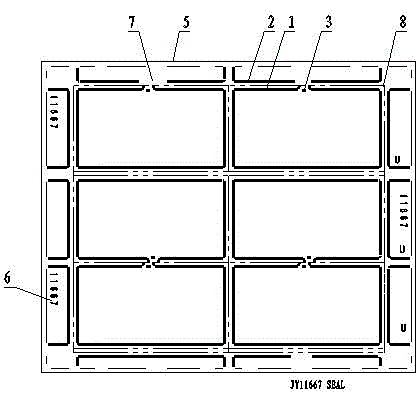

Image

Examples

Embodiment Construction

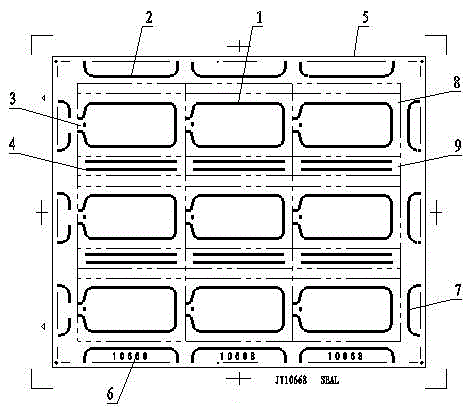

[0017] The glass substrate to be processed in the present invention refers to the entire large glass plate used in the production process of the liquid crystal display, which is generally rectangular. The display sealing frame is printed on the glass substrate to be processed, and the rectangular typesetting area refers to the area corresponding to the glass plate occupied by the product in the pattern of the screen printing plate.

[0018] see figure 2 There are U-shaped auxiliary lines 2 around the typesetting area 8 of the screen printing plate, and there are linear auxiliary lines 4 corresponding to the small glass strips between the sealing frame patterns 1, and the seals 3 of the U-shaped auxiliary lines 2 are all facing to the left. , so the U-shaped auxiliary line 2 on the left is disconnected, which is conducive to the smooth discharge of the gas in the box. The screen printing plate does not have a sealing border pattern opposite to the sealing, so there is only th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com