Processing path optimization method applied to machine tool

A processing path and optimization technology, which is applied in the field of processing path optimization applied to machine tools, can solve problems such as jitter and large amplitude, and achieve the effect of convenient control of trajectory shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention proposes that the algorithm using Tension Spline as an interpolation curve can achieve the advantages of convenient regulation and control through all control points, smooth trajectory and trajectory shape.

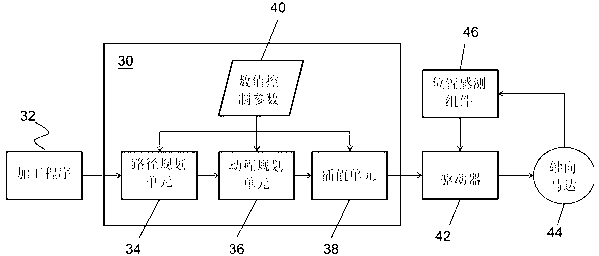

[0032] The present invention is applied to the processing path optimization method of machine tools, wherein the structure and function of the numerical control device of the mentioned mechanical equipment and the principle of interpolation curve B-Spline, Cubic Spline and polynomial curve have been related technical fields Those with ordinary knowledge can understand it, so the following description will only describe in detail the characteristics of the method for optimizing the machining path used in a machine tool according to the present invention.

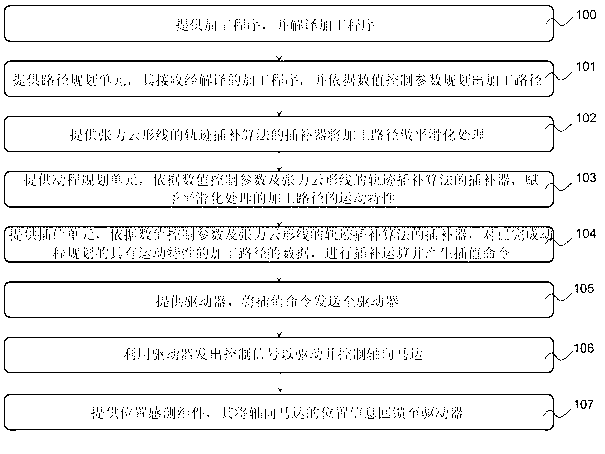

[0033] like figure 1 As shown, the processing path optimization method applied to the machine tool is as follows:

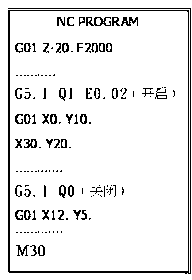

[0034] Step 100: Provide a processing program, and interpret the processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com