Short-circuit protection method for self-excitation push-pull type convertor

A self-excited push-pull and short-circuit protection technology, applied in the direction of output power conversion devices, electrical components, etc., can solve problems such as failure to output normal voltage, failure to start normally, and poor capacitive load capacity at the output end.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

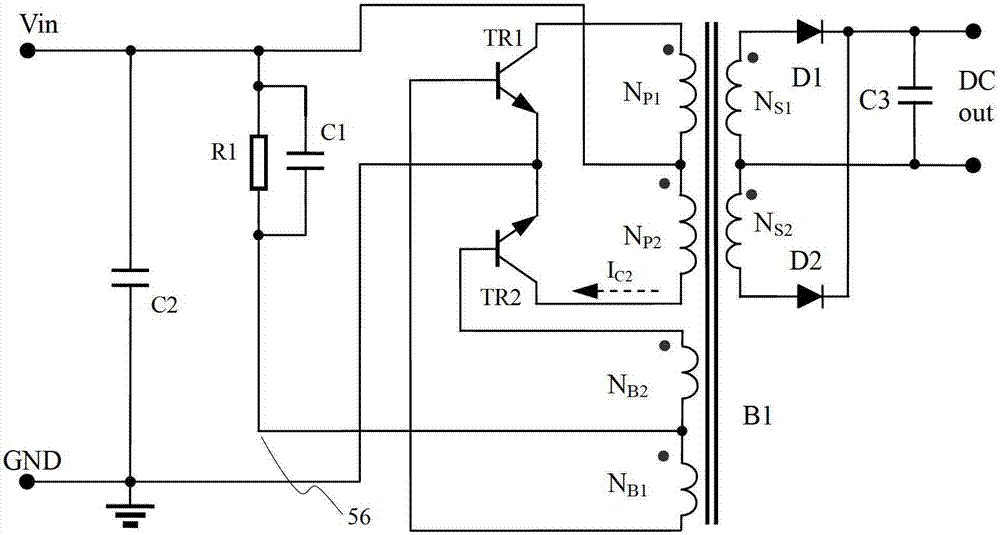

[0062] Embodiment one adopts and figure 1 The same circuit topology is made into a converter with input DC 5V, output DC 5V, and output current of 200mA, that is, the output power is 1W.

[0063] In order to illustrate the effect of Embodiment 1, the self-excited push-pull converter of the prior art used for comparison adopts the same circuit parameters: it includes a transformer B1, and the transformer B1 is composed of a magnetic core and a corresponding coil winding, and the coil winding includes a primary power winding N P1 and N P2 , primary side feedback winding N B1 and N B2 , secondary output winding N S1 and N S2 ; The magnetic core adopts outer diameter of 5.1mm, inner diameter of 2.3mm, and height of 1.7mm, and the material adopts TPW33 magnetic material of Tiantong Holding Co., Ltd. Resistor R1 is 1KΩ; capacitor C2 and capacitor C3 are chip capacitors of 2.2uF / 10V, starting capacitor C1 is a chip capacitor of 0.047uF / 10V; triode TR1 and triode TR2 are switchi...

Embodiment 2

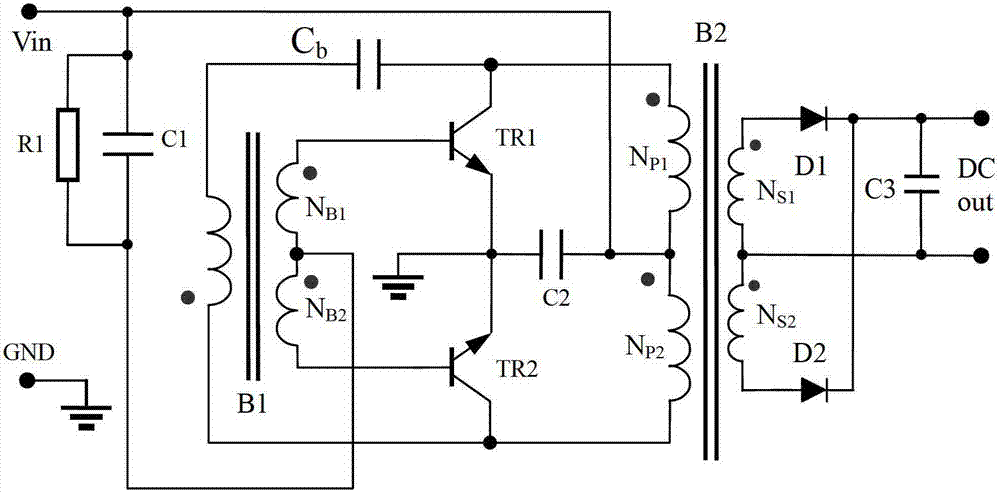

[0084] The prior art self-excited push-pull converter in Embodiment 1 is optimized by adopting the complete method of the present invention:

[0085] Step A, artificially short-circuit the output terminal, adjust the leakage inductance of the transformer, and ensure that the short-circuit protection current at this time is larger than the short-circuit protection limit current; at this time, it is adjusted from 90mA to about 300mA. This current increases rapidly with time, so when adjusting, control The working time of the circuit after power-on;

[0086] Step A1, add a capacitor between the collectors of the two push-pull transistors in the self-excited push-pull converter, and adjust its capacity. It is convenient to debug here, and the variable capacitor 7 / 270pF used in the medium-wave radio is used. , commonly known as double-connection, the capacity can be changed by rotating the handle, so that when an artificial short circuit occurs at the output end, the short-circuit ...

Embodiment 3

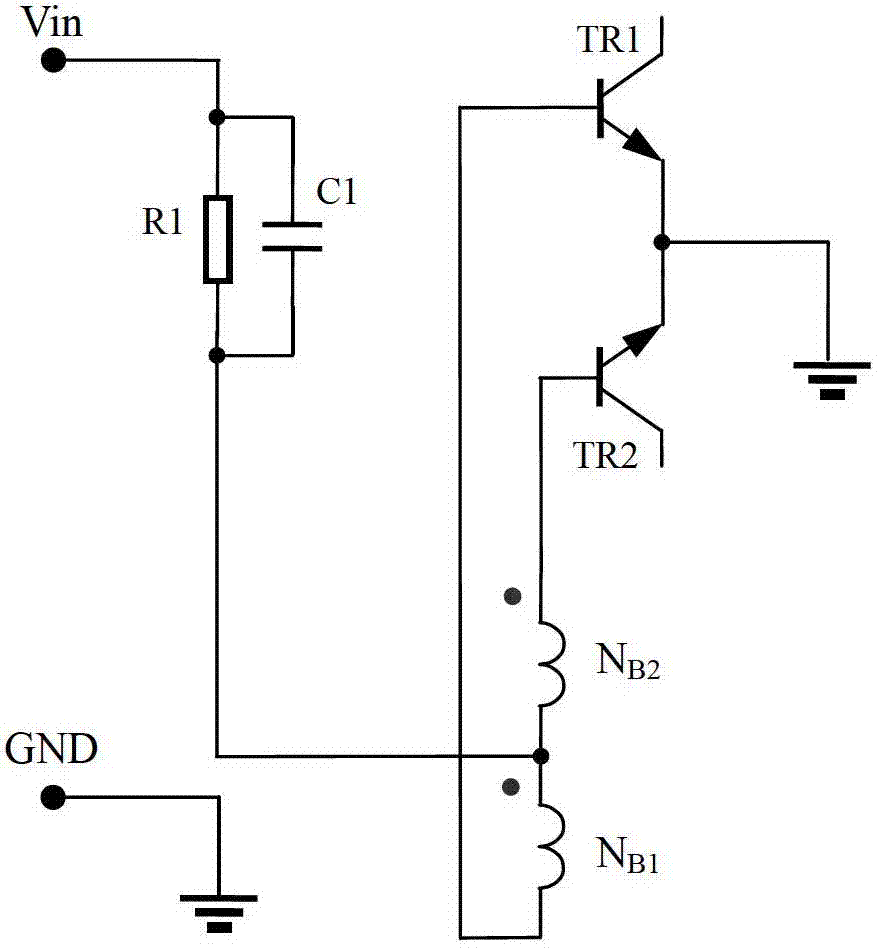

[0095] The third embodiment adopts Figure 9 shows the Royer circuit, with figure 1 The difference is that one end of the starting capacitor C1 is still connected to the center tap of the feedback winding of the self-excited push-pull converter, and the other end is connected to the negative power supply (power ground). The measured performance of the self-excited push-pull converter is exactly the same as the parameters shown in Table 1, and the numerical error is within 3%.

[0096] Using the method of the present invention to optimize the prior art self-excited push-pull converter in Embodiment 3, the steps are as follows:

[0097] Step A, short-circuit the output terminal, and adjust the leakage inductance of transformer B1 to ensure that the short-circuit protection current at this time is greater than the short-circuit protection limit current; at this time, the short-circuit protection current is adjusted from 90mA to about 300mA. This current increases rapidly with ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com