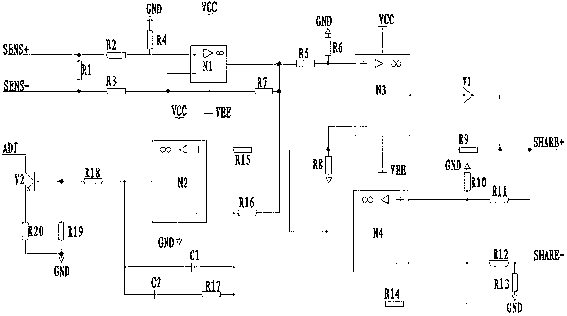

Current equalization circuit for multi-module shunt-wound power supply

A multi-module, parallel technology, which is applied in the direction of electrical components, electric variable adjustment, output power conversion devices, etc., can solve the problems of poor accuracy and low reliability, and achieve improved reliability, high current sharing accuracy, and increased redundancy The effect of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A current sharing circuit for multi-module parallel power supply, comprising: sampling resistor R1, operational amplifier N1, voltage dividing resistor R2, voltage dividing resistor R3, voltage dividing resistor R4, feedback resistor R7, operational amplifier N3, voltage dividing resistor R5 , voltage divider resistor R6, voltage divider resistor R8, feedback resistor R9, operational amplifier N2, voltage divider resistor R15, voltage divider resistor R16, feedback capacitor C1, feedback resistor R17, feedback capacitor C2, adjustment transistor V2, drive resistor R18, divider The piezoresistor R19 and the adjusting resistor R20 also include: a diode V1, an operational amplifier N4, a voltage dividing resistor R10, a voltage dividing resistor R11, a voltage dividing resistor R12, a grounding resistor R13, and a feedback resistor R14.

[0011] The two ends of the sampling resistor R1 are respectively connected to the SENS+ terminal and the SENS- terminal of the output cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com