Encapsulation of reactive components for 1-k systems using coaxial dies

A coaxial nozzle, reactive technology, used in the field of core-shell particle preparation, can solve the problems of organic material size and mechanical instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] equipment

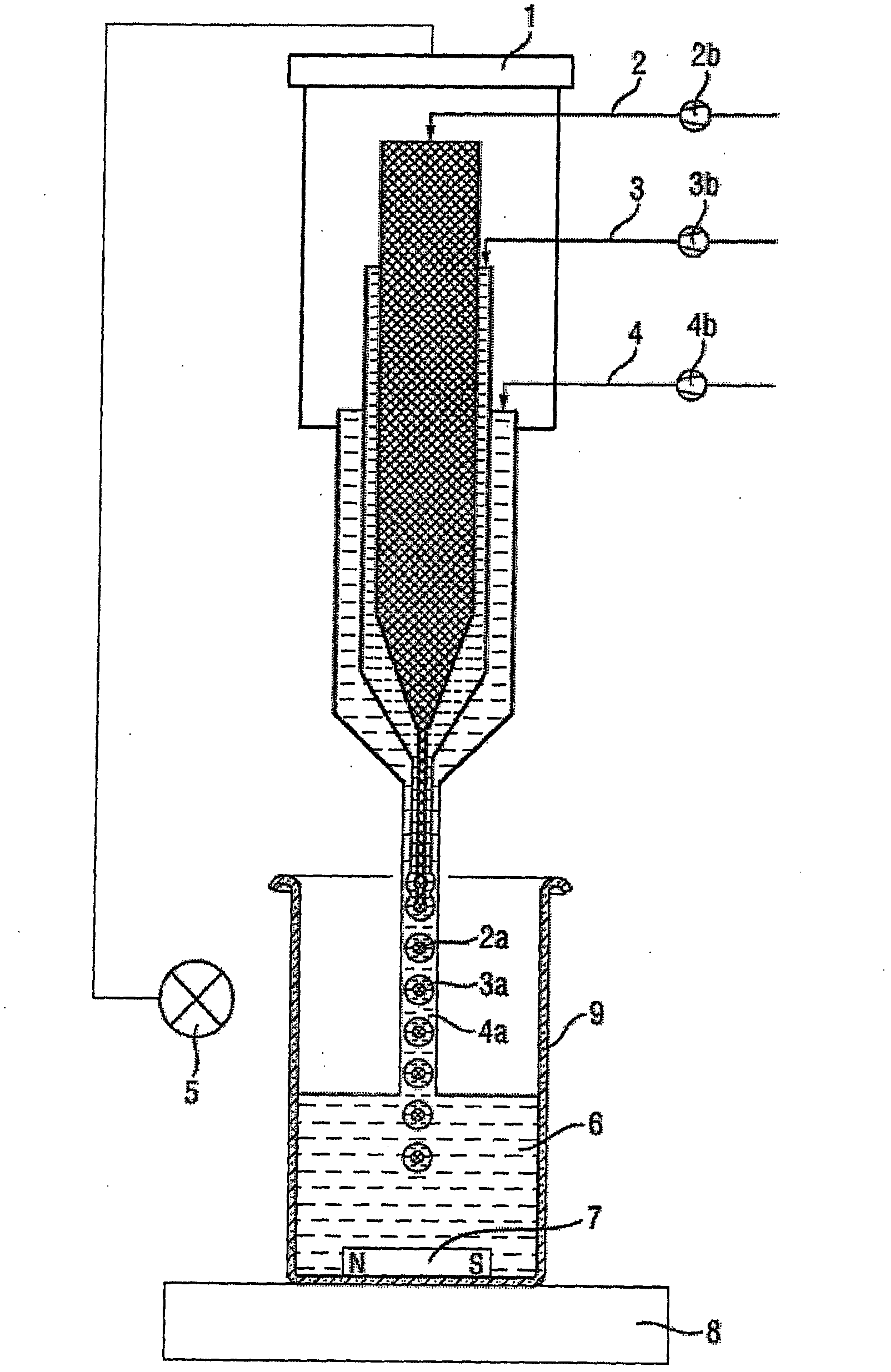

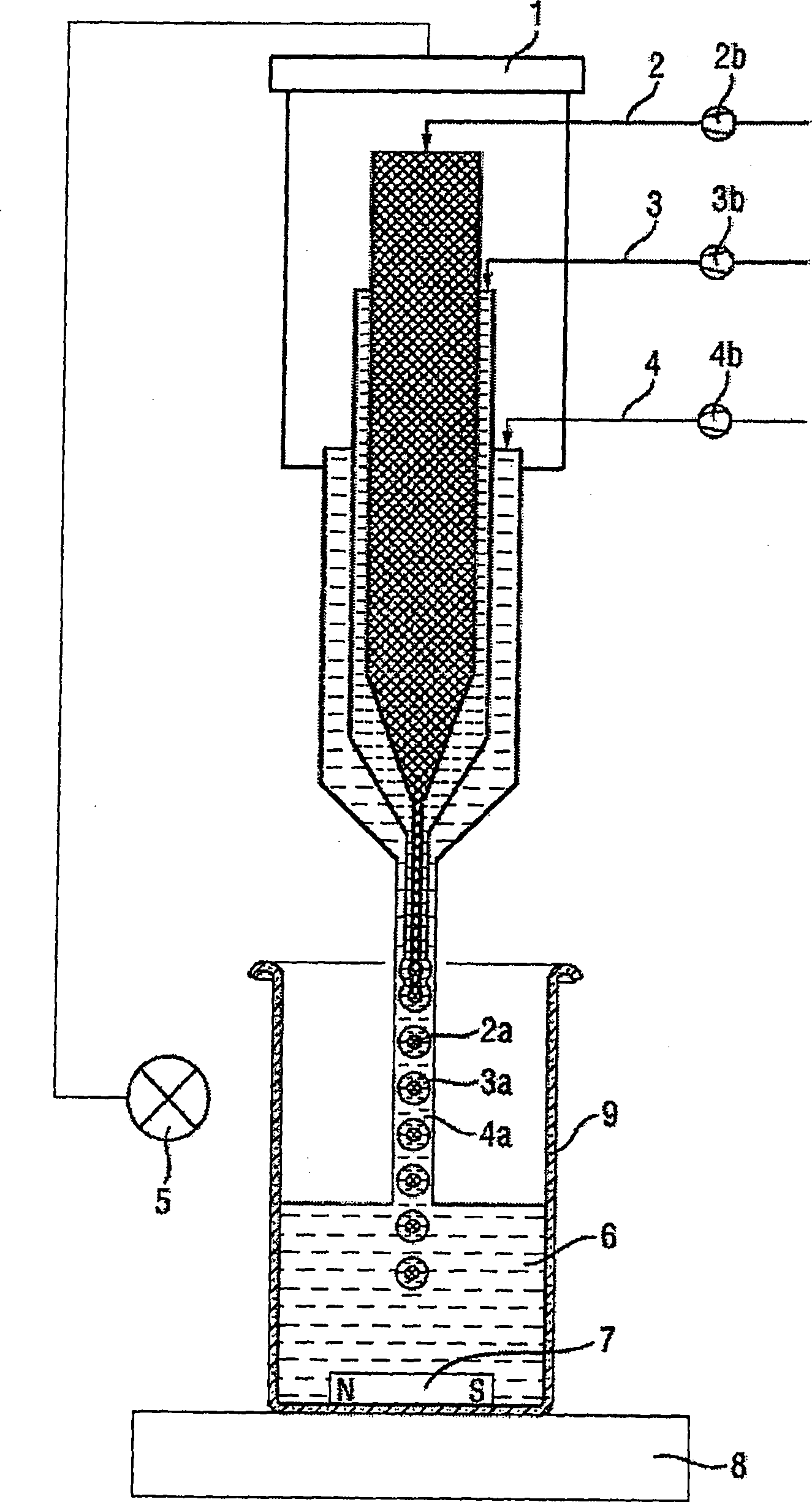

[0077] Refer to accompanying drawing for reference signs figure 1 .

[0078] Rheometer: Haake RheoStress 600

[0079] Measuring body: plate (solvent trap) / cone, DC 60 / 2°

[0080] Sample container filling: 5.9ml sodium silicate solution

[0081] Measuring temperature: 23.0°C

[0082] Measurement: after 120s at 500rpm

[0083] Frequency generator: Black Star 1325 and Jupiter 2000 1

[0084] Transformer: Heinzinger LNG 16-6 (or similar) 1

[0085] Light 5: Drelloscop 2008

[0086] Pump:

[0087] Piston diaphragm pump + pulsation damper: LEWA EEC 40-13 2b

[0088] Gear pump: Gather CD 71K-2 3b

[0089] Flow through pump: for 350 / 500μm nozzle

[0090] Piston diaphragm pump + pulsation damper for sodium silicate solution: 1.5-5 l / h

[0091] Gear pump for initiator-oil suspension: 1-2 l / h

[0092] Pretreatment of sodium silicate solution

[0093] 1.3 liters of commercial sodium silicate solution with a solids content of 40% by weight and a dynamic vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com