Variable, double, straight-line piping type of water-saving toilet

An adjustable toilet technology, applied in flush toilets, water supply devices, urinals, etc., can solve the problems of limited production characteristics, difficult assembly operations, and difficult assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

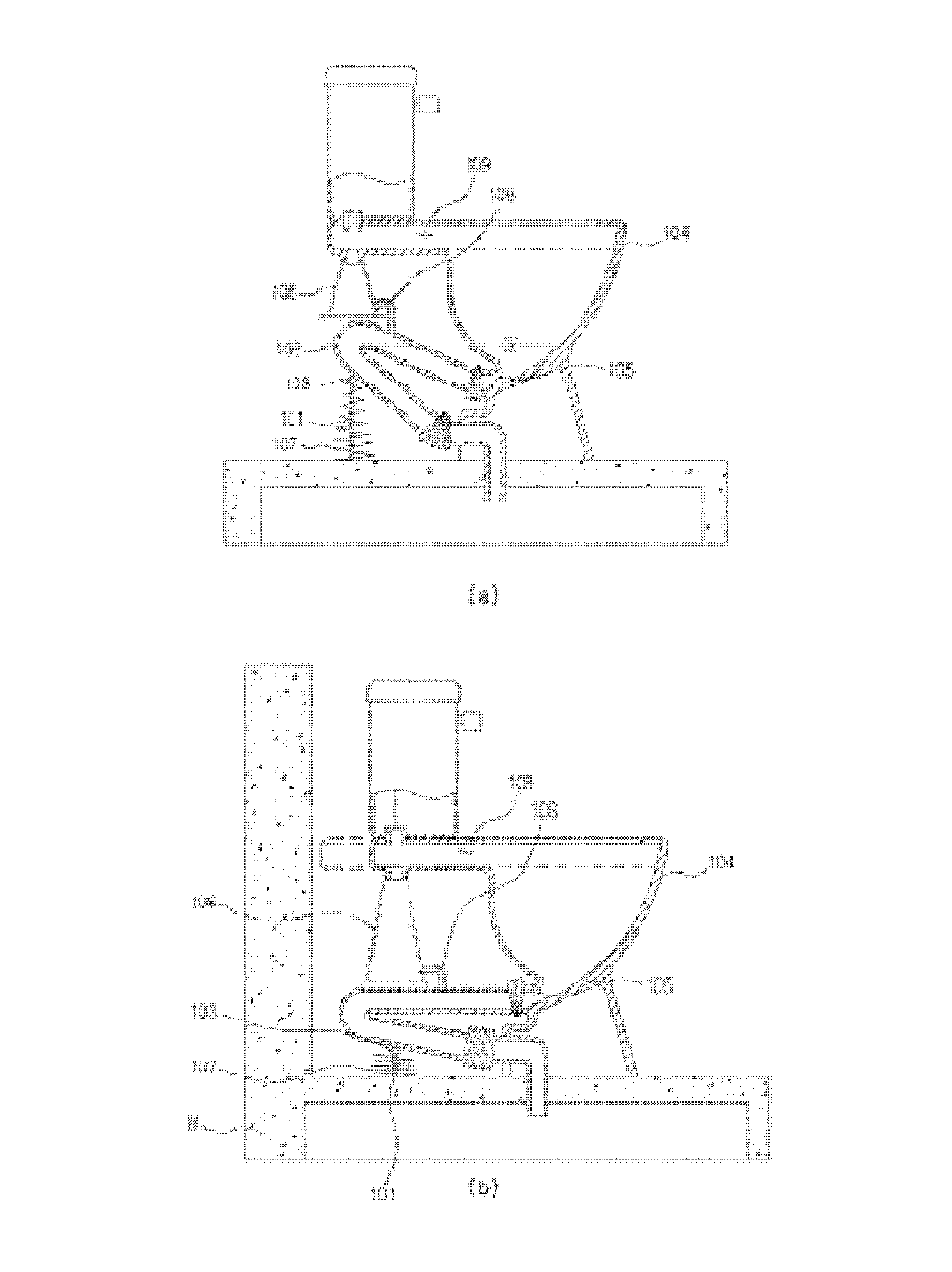

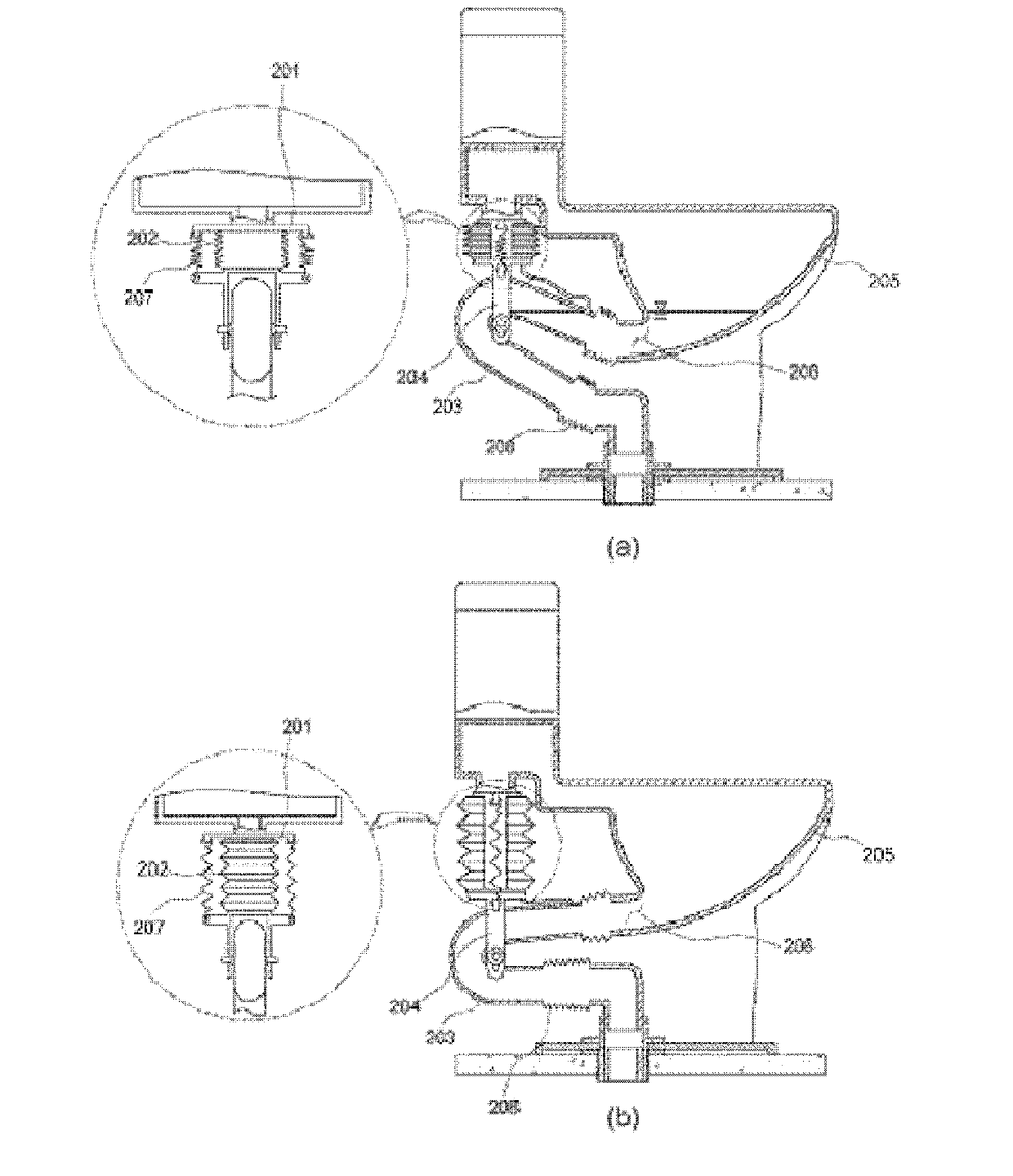

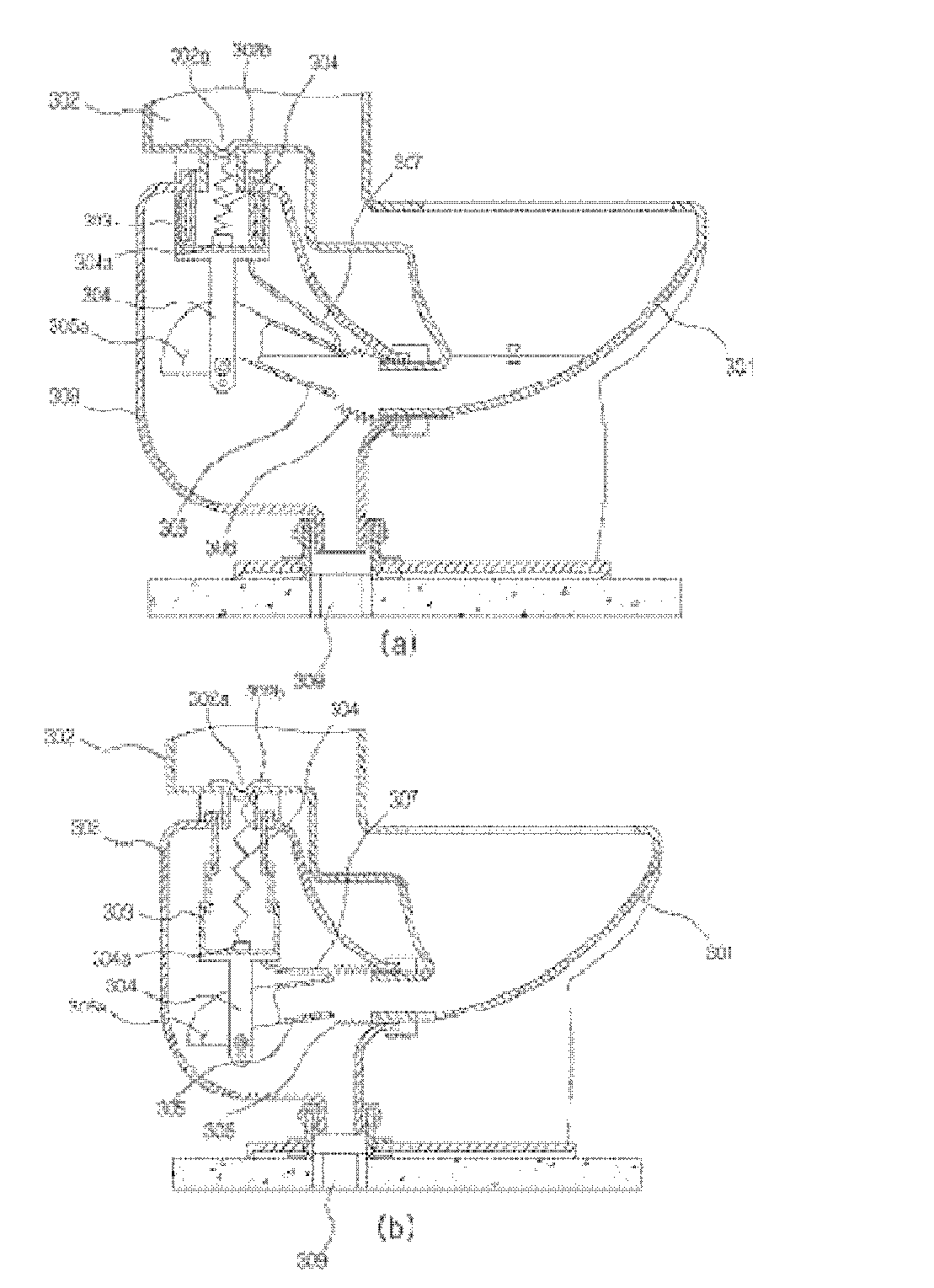

[0056] Hereinafter, the adjustable double straight pipe water-saving toilet according to the present invention will be described in detail with reference to the accompanying drawings. Fig. 5 is an exploded perspective view of the internal structure of an adjustable double straight pipe water-saving toilet according to a specific embodiment of the present invention; Fig. 6 is a view of the main part of an adjustable double straight pipe water-saving toilet according to a specific embodiment of the present invention An exploded perspective view; FIG. 7 is an exploded perspective view of an adjustable double straight pipe and an anti-deformation port according to a specific embodiment of the present invention; FIG. 8 is a front view of an anti-deformation port according to a specific embodiment of the present invention; FIG. The bottom view of the adjustable double straight pipe according to the specific embodiment of the invention; Fig. 10 to Fig. 12 are the working state section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com