Brake cylinder device and disk brake device

A brake cylinder and cylinder body technology, applied in the field of disc brake devices and brake cylinder devices, to achieve the effect of miniaturization of radial dimensions, improvement of space efficiency, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

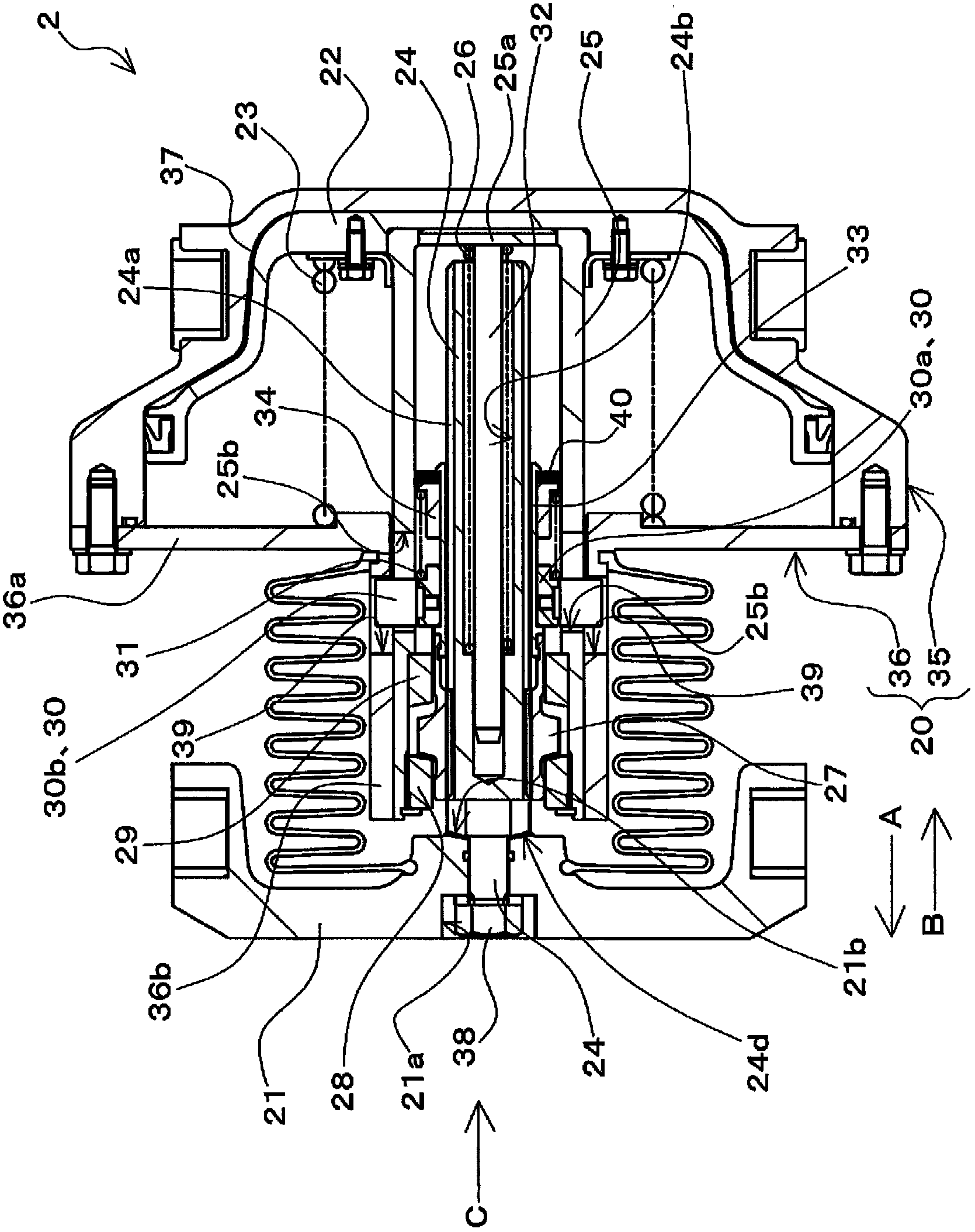

[0058] Next, a brake cylinder device 3 according to a second embodiment of the present invention will be described. Figure 21 It is a sectional view of the brake cylinder device 3 of the second embodiment. Figure 21 The shown brake cylinder device 3 is provided as a brake cylinder device equipped in the disc brake device 1 similarly to the brake cylinder device 2 of the first embodiment. In addition, in Figure 21 In FIG. 3 , the cross-section is not shown but the outer diameter is shown for some components of the brake cylinder device 3 .

[0059] The brake cylinder device 3 includes the cylinder main body 20, the brake output part 21, the piston 50, the piston spring 23, the threaded shaft 24, the guide pipe 25, the thrust spring 26, and the clutch nut similarly to the brake cylinder device 2 of the first embodiment. 27. Front clutch 28, rear clutch 29, stopper 30, adjustment spring 31, thrust spring guide 32, adjustment sleeve 33, spring stopper 34, nut member 38, beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com