Anti-drag wear-resistant coupling bionic surface of agricultural machinery farming component

A technology for agricultural machinery and components is applied in the field of drag reduction and wear resistance coupled bionic surfaces of agricultural machinery farming components, which can solve the problems of large working resistance, poor wear resistance and high energy consumption, reduce farming resistance and use costs, and improve wear resistance. effect on performance and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

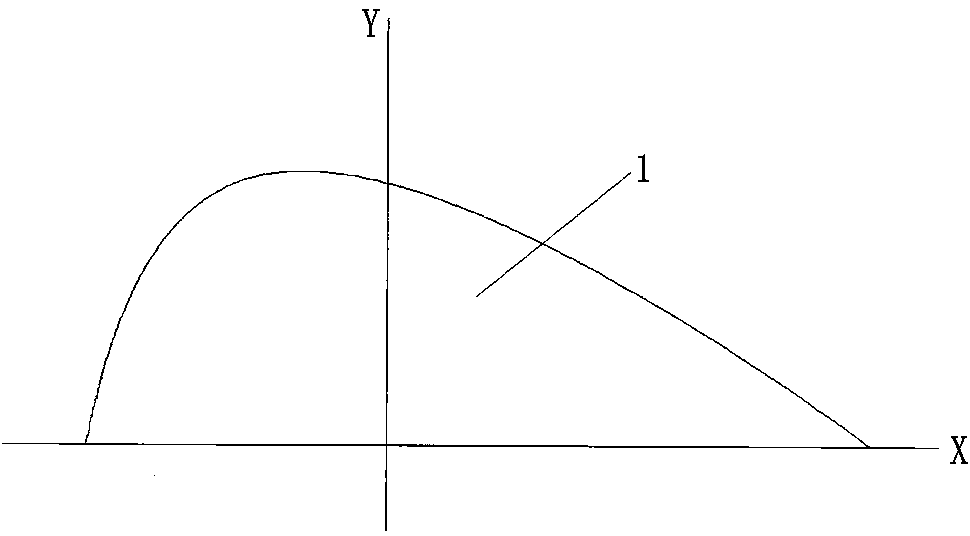

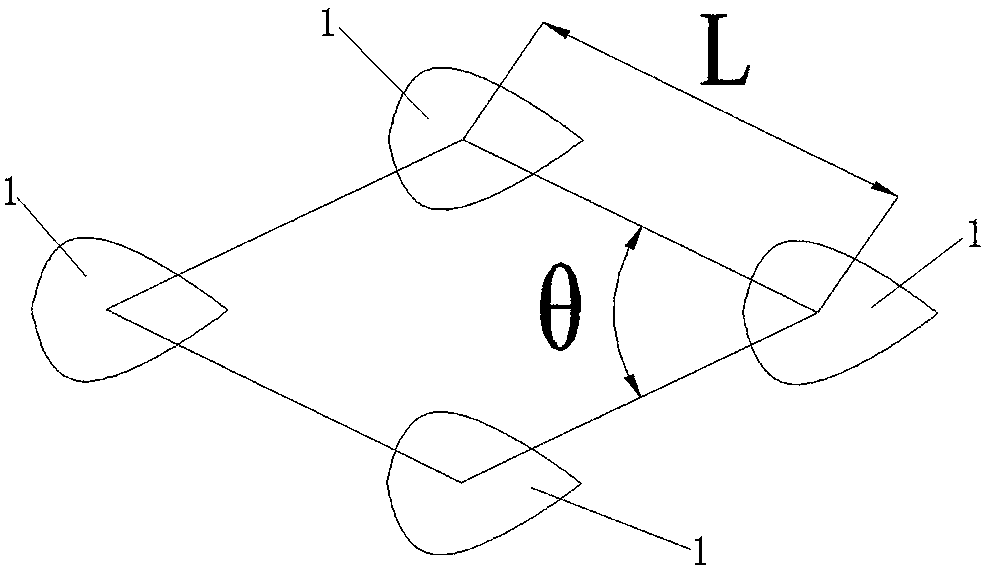

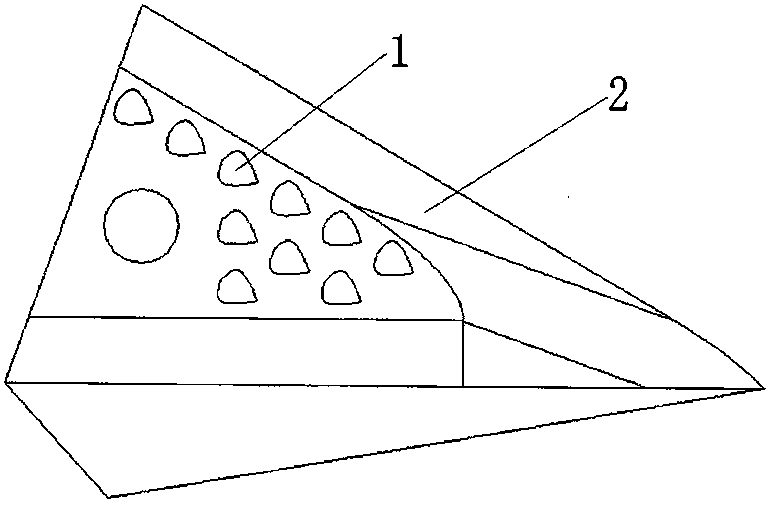

[0026] The invention designs the wear-resistant and drag-reducing bionic protrusions on the surface of the soil-contacting parts of the agricultural machinery and their arrangement according to the excavating organs and the excavating action parameters of the mole known as the "living excavator". The mole's body structure is very suitable for underground activities and digging. The mole's extremely high digging efficiency is due to its unique geometric structure of the front paws and the contact angle between the claws and the soil during the digging process. The first factor ensures that the mole is subjected to less soil resistance in the process of excavating the soil underground, and realizes continuous and efficient excavation. Can continue to dig.

[0027] The present invention combines the two important parameters of the geometric profile of the mole's claw and the contact angle between the mole's claw and the soil, and designs a drag-reducing and wear-resistant bionic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com