Sonic toothbrush vibration structure for effectively reducing vibration of handle

A handle and sound wave technology, used in dentistry, cleaning teeth, medical science, etc., can solve the problems of increasing body vibration and easy damage, and achieve the effect of reducing handle vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the specific embodiments of the accompanying drawings.

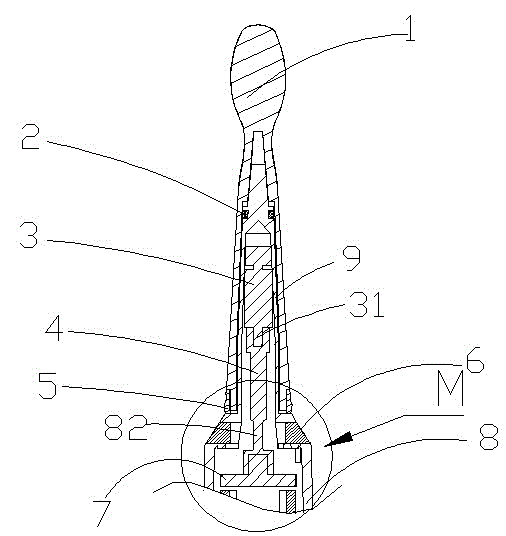

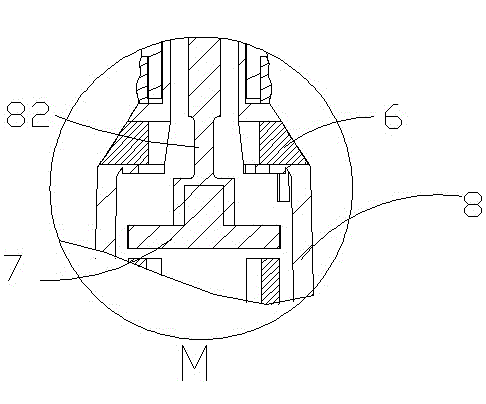

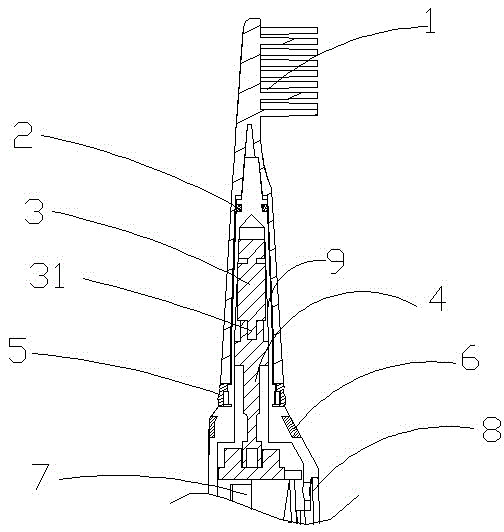

[0025] Figure 1 to Figure 9 It is a schematic diagram of the structure of the present invention.

[0026] The reference signs therein are: toothbrush head body 1, muffler ring 2, micro motor 3, protruding column 31, support rod 4, color ring 5, elastic body rubber coating 6, bracket 7, handle 8, first damping rib 81, the second damping rib 82, the transmission rod 9.

[0027] Such as Figure 1 to Figure 9 As shown, the present invention

[0028] A sonic toothbrush vibration structure that effectively reduces the vibration of the handle, including a handle 8 and a micro motor 3 that can generate vibration output, wherein the handle 8 is molded as a whole with a transmission rod 9 that can transmit vibration to the toothbrush head body 1, the micro The motor 3 is fixed in the upper inner cavity of the transmission rod 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com