Paper shredding fan

A fan and paper shredding technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of reducing paper shredding efficiency and increasing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

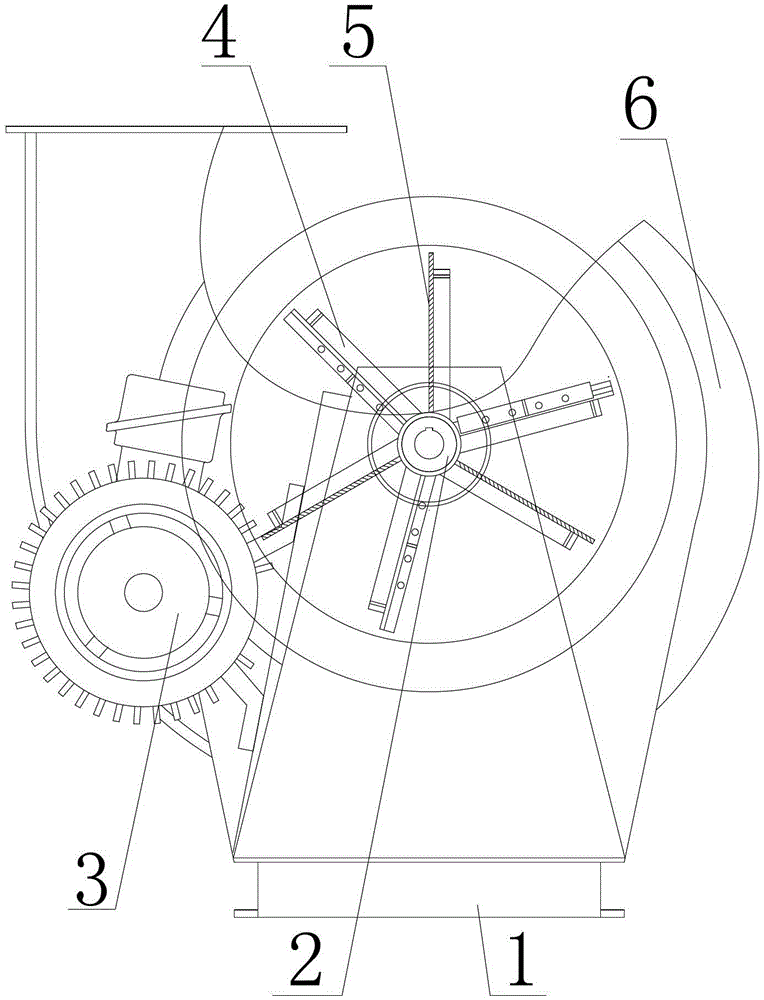

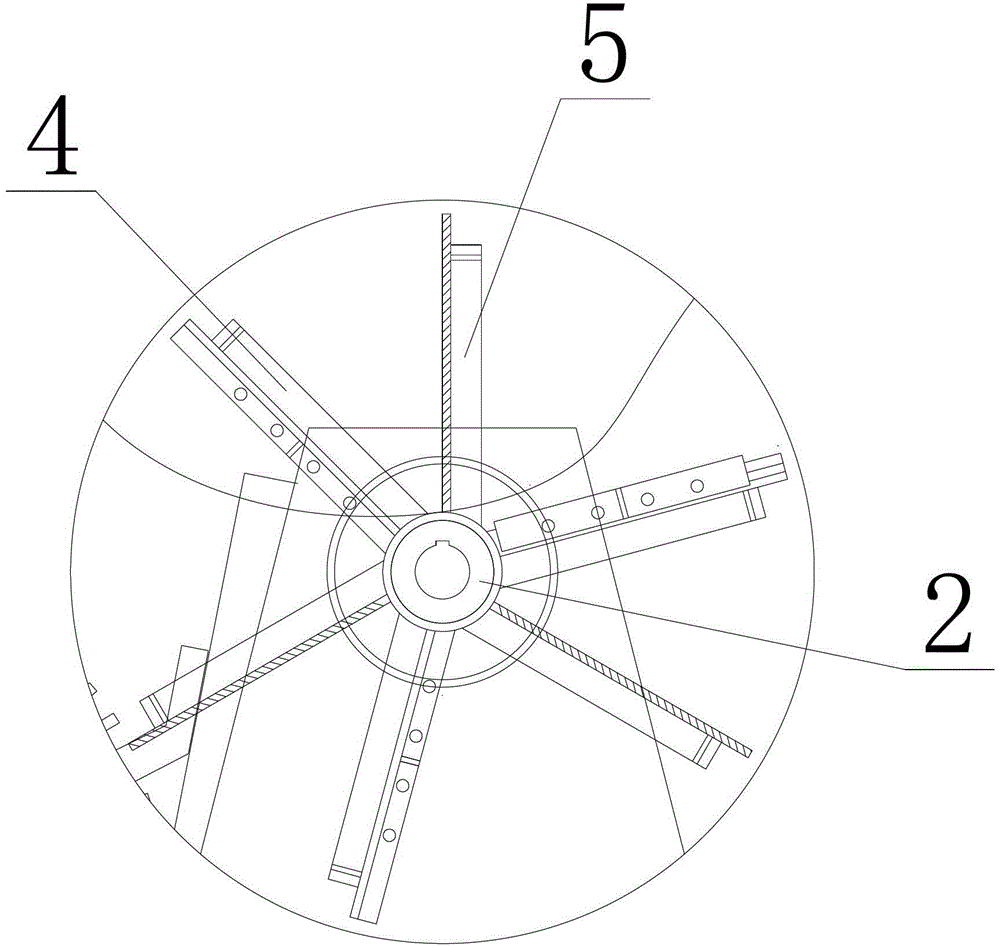

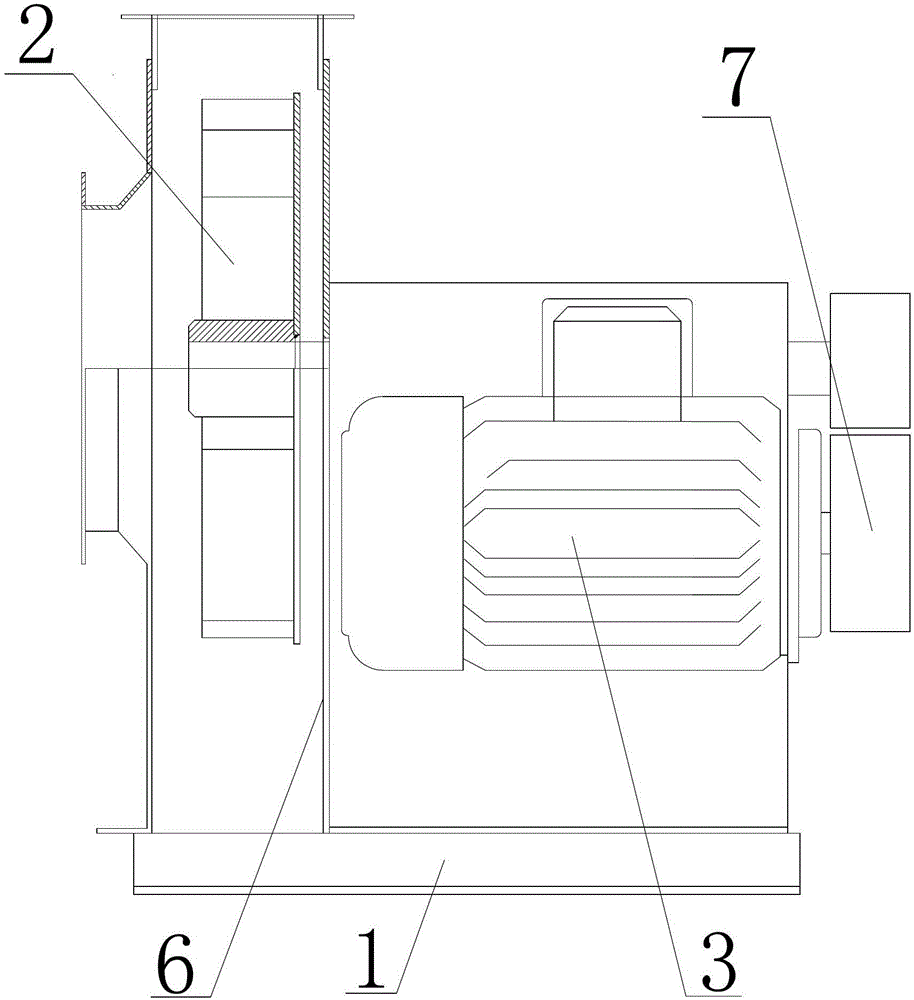

[0014] The present invention is described below in conjunction with accompanying drawing.

[0015] as attached Figure 1-3 The shown paper shredding fan according to the present invention includes a chassis 1, a fan housing 6, an impeller seat 2, a motor 3, fan blades 4 and blades 5; the chassis 1 is provided with a fan housing body 6; the fan housing 6 is provided with an impeller seat 2 through the main shaft; the rear end of the fan housing 6 is provided with a motor 3; the output shaft of the motor 3 and the main shaft of the impeller seat 2 pass through a transmission device 7 Connected; the impeller seat 2 has a plurality of fan blades 4 in an annular array; the impeller seat 2 also has a plurality of blades 5 in an annular array; the number of the fan blades 4 and the blades 5 is three; the knives 5 Located in the middle of two adjacent blades 4; the blade 5 is made of tungsten steel.

[0016] When the shredder fan is in use, first put the waste paper at the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com