Low Si-Mg ratio and low RE-Mg nodularizer

A technology of nodularizing agent and rare earth magnesium, which is applied in the field of material processing, can solve the problems of white mouth increase and unfavorable control of thin-walled parts, reduce silicon content, reduce production cost, and eliminate carbide and thick-walled parts of thin-walled parts. The effect of fragmented graphite on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

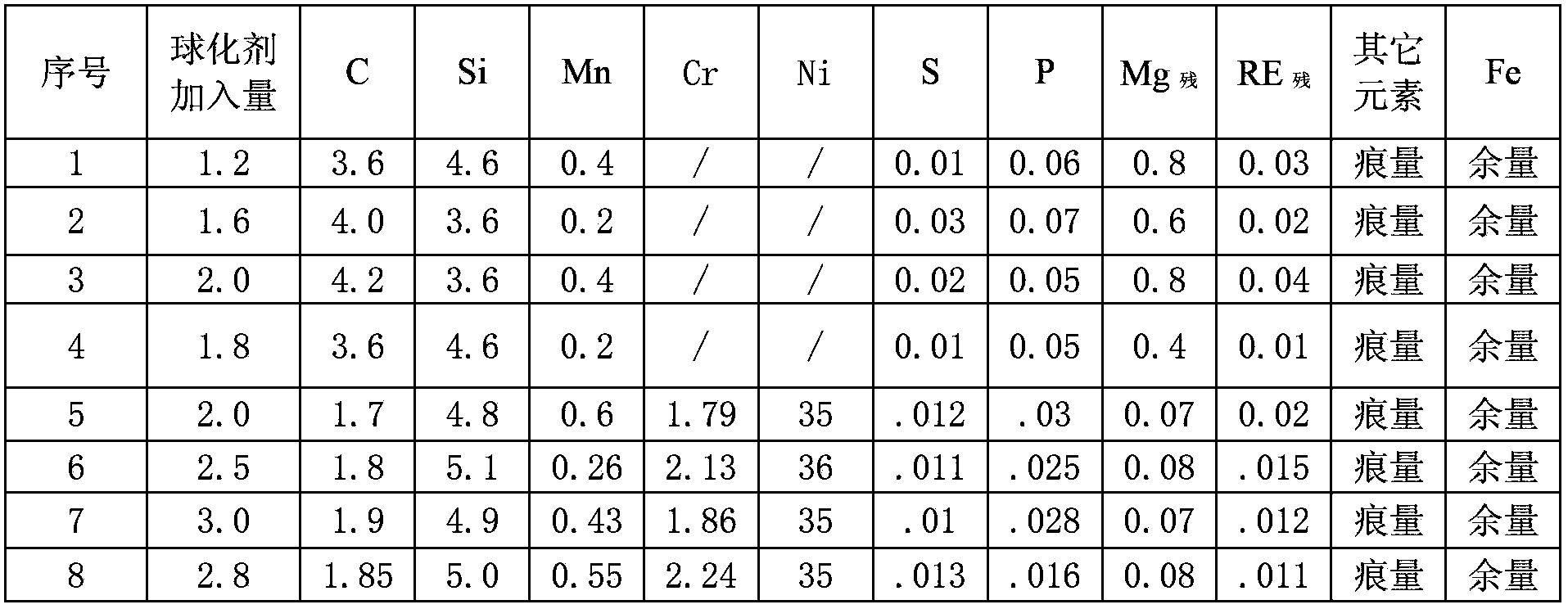

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in combination with specific embodiments.

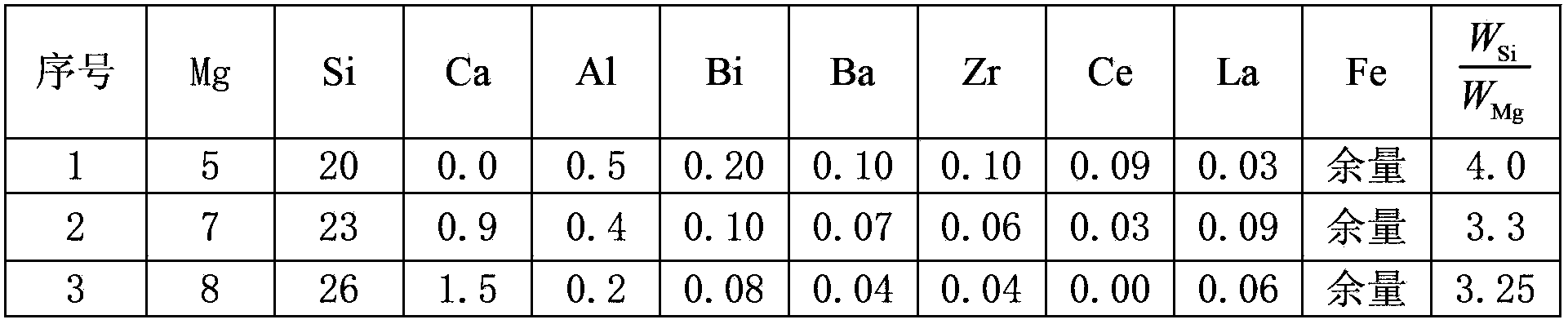

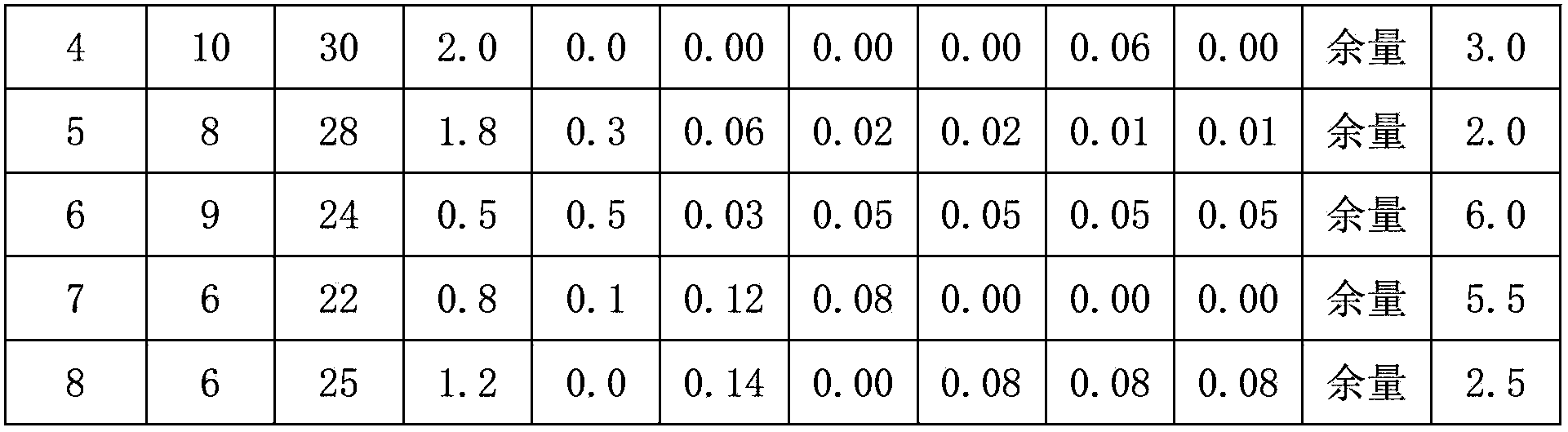

[0011] The invention discloses a low Si / Mg ratio, low rare earth magnesium nodulizer, which is used for the production of high-toughness ductile iron and high-nickel nodular iron. The nodulizer is composed of the following components in mass percentage: Mg5%-10%, Si20%-30%, Ca≤2%, Al≤0.5%, Bi≤0.2%, Ba≤0.1%, Zr≤0.1%, Ce<0.1% and La<0.1%, the rest is Fe.

[0012] In the above-mentioned spheroidizing agent composition of the present invention, the composition of each chemical element and the reason of content limitation are respectively described as follows:

[0013] In order to ensure the spheroidization treatment of molten iron and meet the spheroidization requirements of different amounts of molten iron, the content of magnesium in the nodulizer is controlled within the range of 5%-10%; in order to enhance the silicon element in the inoculant to the molten iron The inocu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com