Method for controlling nail shooting process of continuous casting slab

A technology of process control and continuous casting slabs, which is applied in the field of control of the continuous casting slab single gun nailing measurement process, can solve the problems of parameter control, failure to find the nails, and dangers, etc., to overcome poor accuracy and avoid wasteful, overcoming dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment the present invention will be further described.

[0022] This nailing control method is used when measuring the thickness of solidified slab shell by nailing in continuous casting production.

[0023] Before nailing, the collected parameters related to nailing are substituted into relevant formulas, and after calculation, the nailing time and the time when the nailing slab reaches the cutting point are obtained.

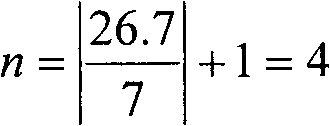

[0024] Relevant parameters of the casting machine: pulling speed V=1m / min, distance L from the nailing point to the initial point of the cutting machine 0 =26.7m, billet cut to length l 0 =7m, cutting gap l 1 = 0.01m and the cutting allowance of the nail blank sample l 2 = 0.15m. After substituting the parameters, it is calculated:

[0025] (1) Determine the nailing time

[0026] n = | 26.7 7 | + 1 = 4 piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com