Electric spindle structure of work bench

A technology of electric spindle and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increasing equipment investment cost and poor versatility of workbench electric spindle, so as to reduce input cost and have good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

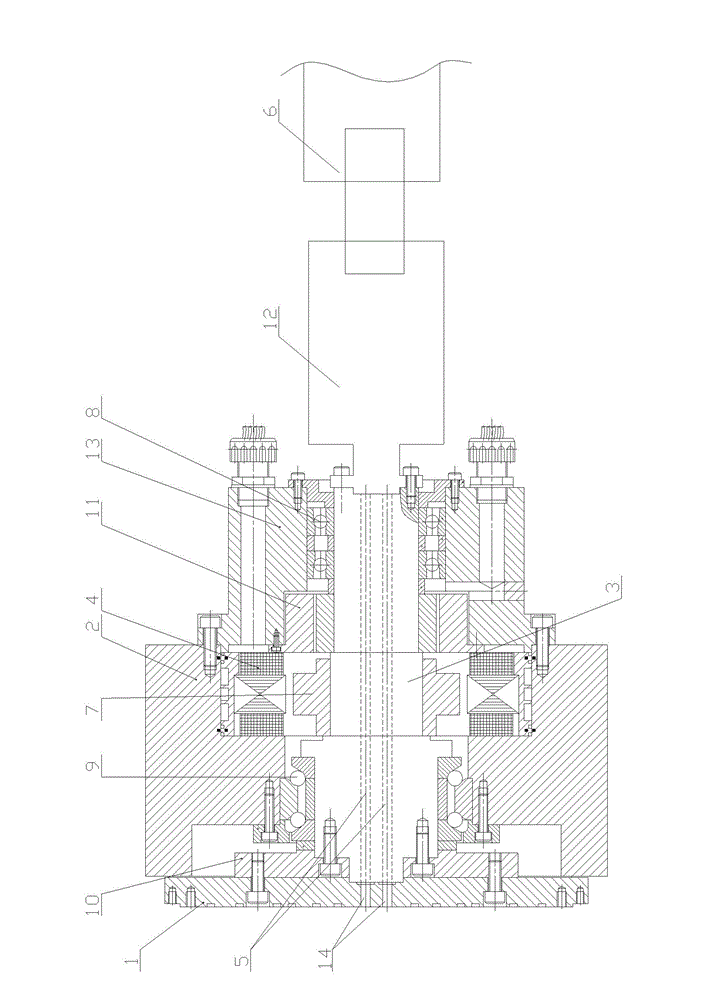

[0009] See figure 1 , which includes a front cover 1, a housing 2, a main shaft rear cover 13, a rotating shaft 3, a motor 4, and a resolver 5. The central area of the rotating shaft 3 is provided with an air passage 5, and the air passage 5 is connected to a vacuum valve 6 at its tail. The cavity formed by the body 2 and the main shaft back cover 13 is equipped with a rotating shaft 3, a motor 4, and a resolver 11. The output end of the rotating shaft 3 is fastened to the front cover 1, and the rotating shaft 3 is fastened to the rotor 7 of the motor 4. The resolver 11 is set on one end of the rotating shaft 3. There are at least two air passages 5 in the central area of the rotating shaft 3. The tail of each air passage 5 is connected to the vacuum valve 6 through a rotary joint 12. The front cover 1 corresponds to each air passage 5. There are through holes 14 in the positions respectively.

[0010] The rear end of the rotating shaft 3 is supported in the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com