Platform for disassembling and assembling oil cylinder piston

A piston and oil cylinder technology, applied in the field of engineering construction equipment manufacturing and maintenance, can solve the problems of large tightening torque and difficult disassembly and assembly, and achieve the effects of fast progress, high replacement work efficiency, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

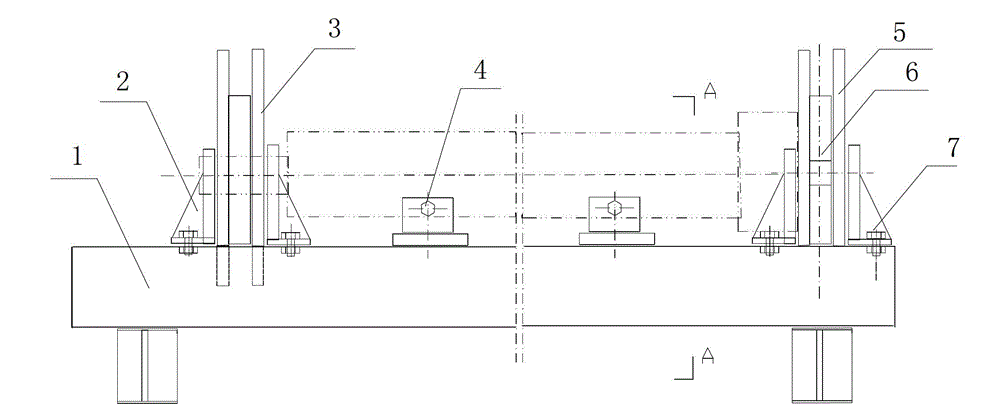

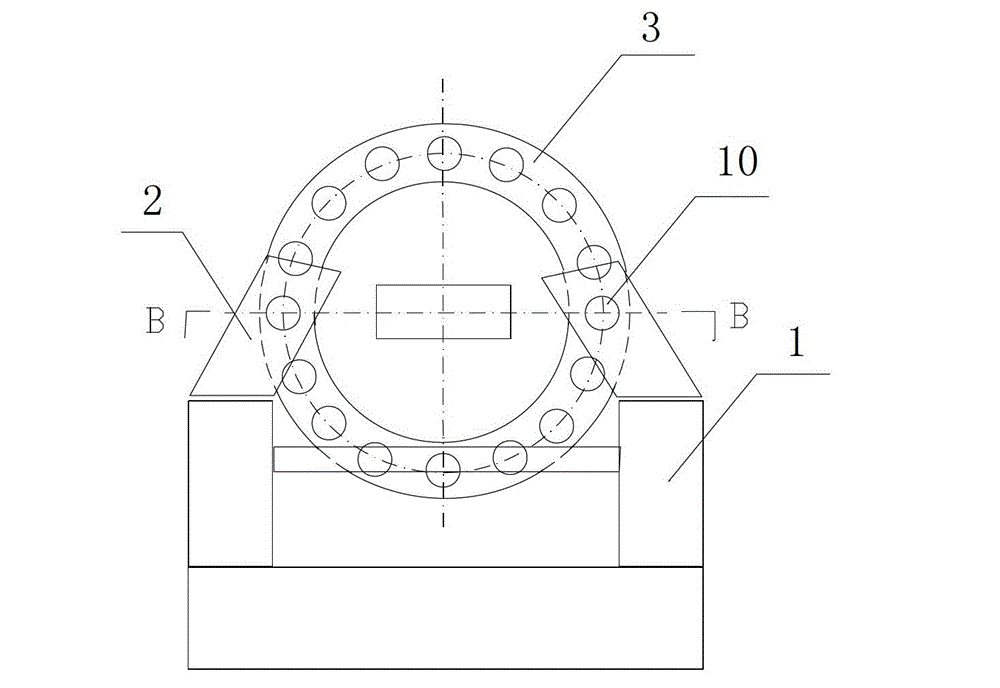

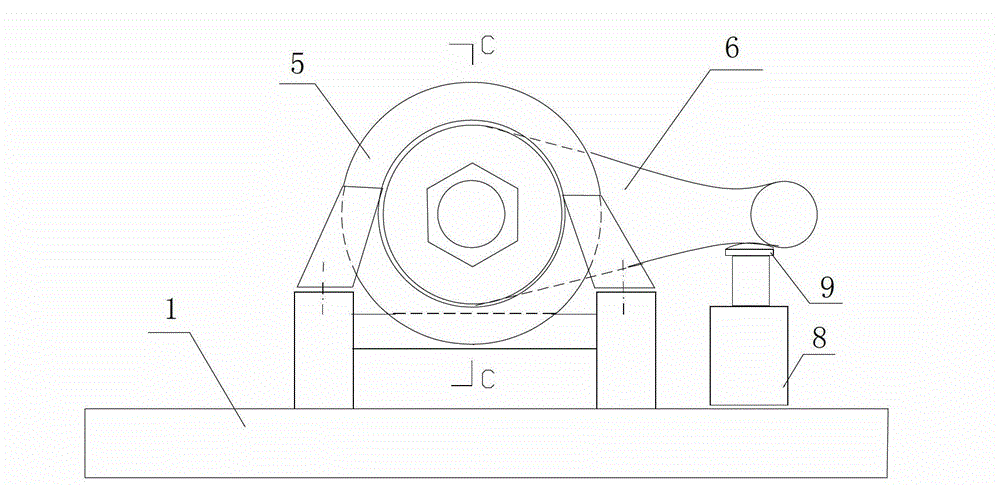

[0021] see Figure 1-Figure 12 , the present invention has a base 1, the key technology of which is that the base 1 is combined into a frame structure by section steel, the ear end brackets 2 are respectively installed through bolts 7 on both sides of one end of the base 1, and the turntable 3 is installed between the ear end brackets 2, and the turntable 3. It is composed of an inner disc 11 with a rectangular hole in the center and an outer disc 12 with shaft holes evenly distributed on the outer ring. The turntable 3 is connected with the ear end bracket 2 by a pin shaft 10 through the shaft hole. The rectangular hole in the center of the turntable 3 is used to cover the On the ear end of the piston rod, the distance between the shaft holes of the outer disk 12 can be determined according to the jack stroke, and at least one hole distance can be rotated at a time when jacking up; The upper welding bracket ring 13 constitutes the rod end bracket 5, and a wrench 6 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com