Double-U ventilation system for fully-mechanized caving coal working face

A ventilation system and fully-mechanized roof caving technology, which is applied in mine/tunnel ventilation, mining equipment, earthwork drilling, etc., can solve the difficulty of ventilation system management, increase the amount of roadway excavation, and reduce the coal recovery rate in the mining area To achieve high-yield and high-efficiency fully mechanized top-coal caving mining, change the air leakage flow field and gas distribution, and achieve the effects of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

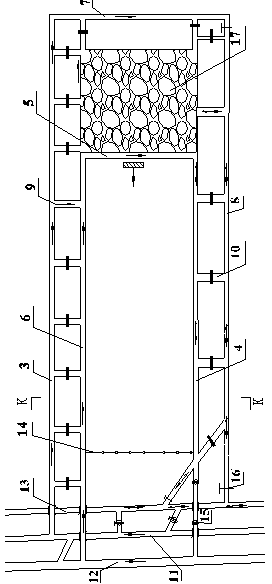

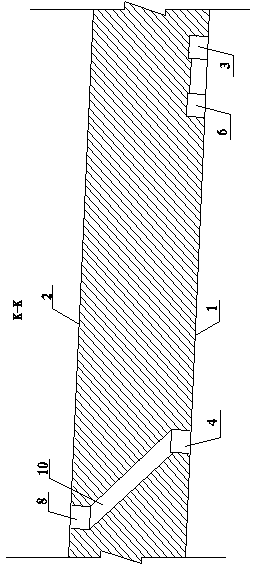

[0022] figure 1 As shown, it is the U+U-shaped ventilation system layout diagram of the fully-mechanized top-coal caving face. The U+U-shaped ventilation system of the fully-mechanized top-coal caving face includes the following parts:

[0023] , Fully mechanized mining top coal caving face belt slot and return air slot are arranged along the coal seam floor, and are respectively connected with the belt lane and return air lane in the mining area, and connected with the belt lane in the mining area on the return air slot at the bottom Air door 15 is established near the top-coal caving face to form a basic internal U-shaped ventilation system for coal mining production at the bottom of the fully mechanized top coal caving face.

[0024] , The air inlet trough of the fully mechanized top-coal caving face, the ventilation connection roadway is arranged along the coal se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com