Muffling structure of fan filter muffler

A technology of fan filter and muffler, which is applied in the field of fan filter muffler noise reduction structure, improved structure, and fan filter muffler noise reduction device. Improved sound effect, compact structure, and reduced thickness of the sound-absorbing layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

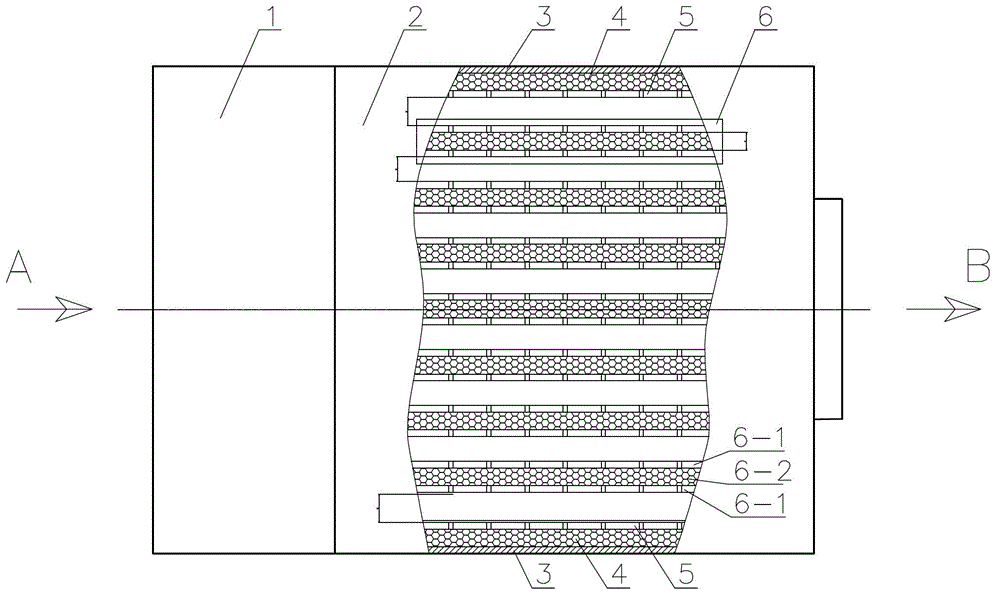

[0012] Such as figure 1 Shown: this filtering muffler comprises parts such as air filtering device 1, muffler device 2.

[0013] The present invention comprises shell plate 3, shell sound-absorbing layer 4, shell perforated plate 5, middle sound-absorbing sheet 6 and other components. The shell sound-absorbing layer 4, the shell perforated plate 5 and several middle sound-absorbing sheets 6 are all arranged on the shell plate 3, and the middle sound-absorbing sheet 6 is covered by the middle perforated plate 6-1 covering the middle sound-absorbing layer 6- 2 components; several middle mufflers 6 are evenly arranged along the normal direction of the air flow channel, and the distance between adjacent middle mufflers 6 and the distance between the middle muffler 6 and the shell perforated plate are equal (both are X), and X is is the width of the air c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com