Full-serial plate shell heat exchanger

A heat exchanger, plate and shell technology, applied in the field of plate and shell heat exchangers, can solve the problems of unfavorable saving of land resources, unfavorable energy saving and emission reduction, increase of equipment cost, etc., and achieve raw material saving, light weight and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

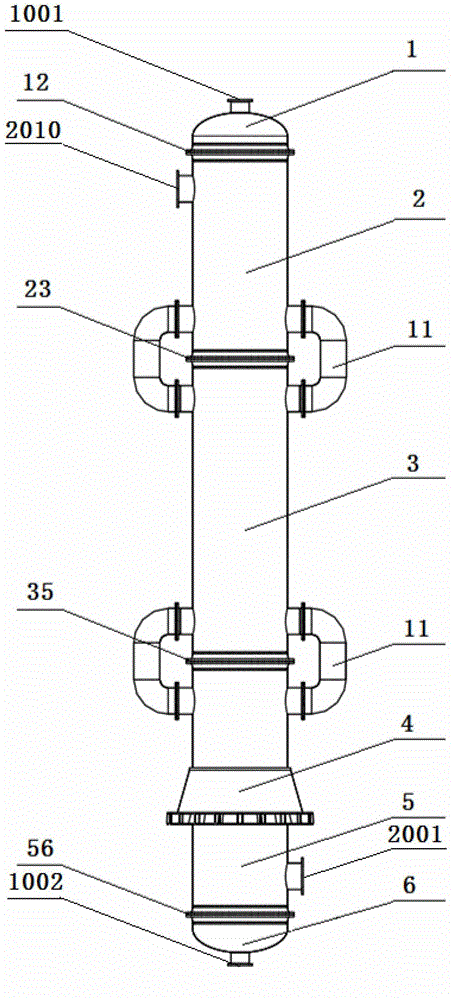

[0045] refer to Figure 1 to Figure 9 , a full series plate and shell heat exchanger, the cold and hot medium are arranged in counter flow. The hot medium goes straight in and out, and the cold medium goes in and out from the side. The invention relates to a full series plate and shell heat exchanger, including a head, a cylinder, a skirt, a plate bundle, a fluid distributor, a heat medium inlet, a heat medium outlet, a cold medium inlet, a cold and heat medium outlet, etc. part.

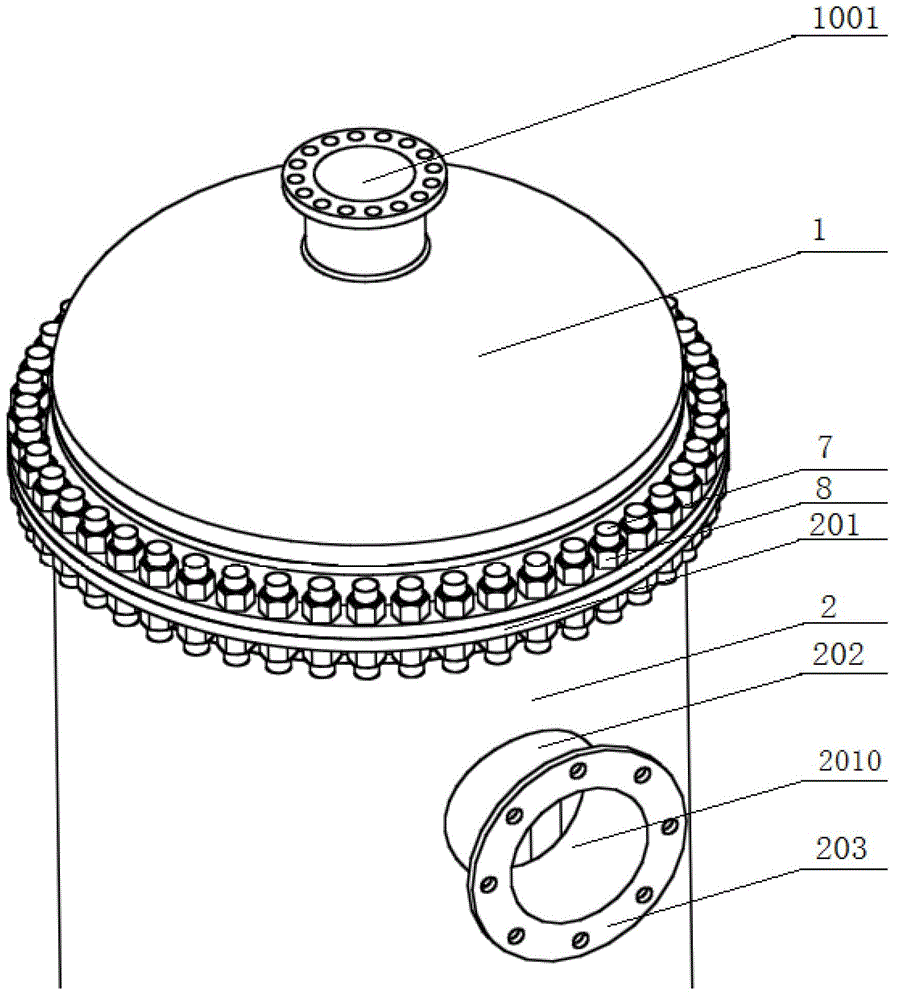

[0046] The full series plate and shell heat exchanger consists of an upper head 1, a lower head 6, a stage III cylinder body 2, a stage II cylinder body 3, a stage I cylinder body 5, a skirt seat 4, a plate bundle 9, a fluid distribution device 10 and so on.

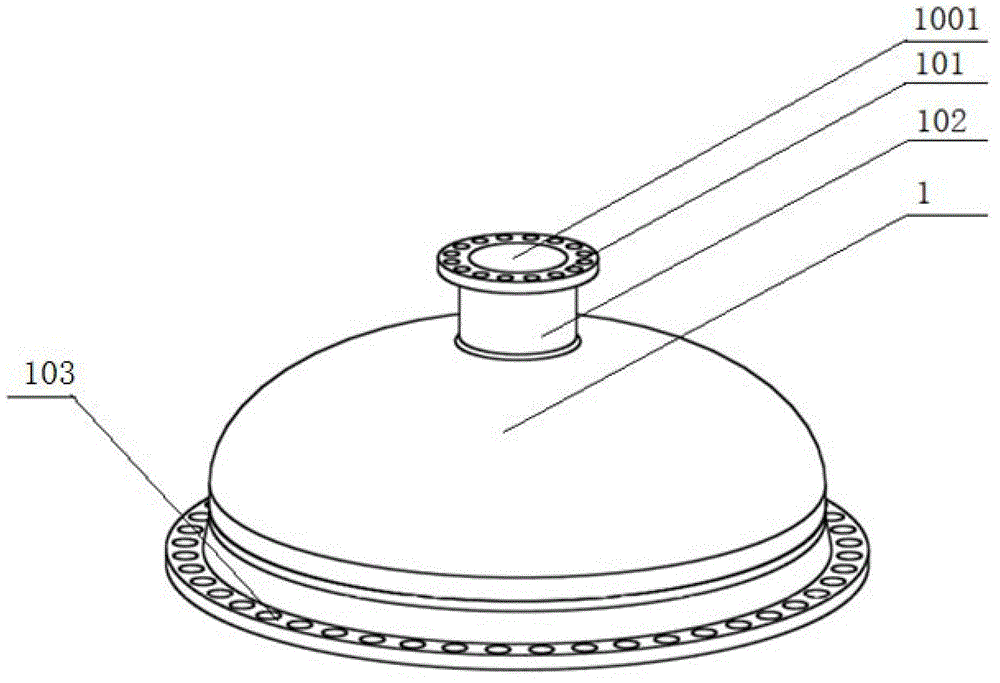

[0047] Upper head 1 is composed of forming head 1, connecting flange 101, head connecting pipe 102, equipment flange 103, etc. The rotating surface of forming head 1 can be divided into elliptical, spherical, butterfly, conical and other sh...

example 2

[0057] The manufacturing process of Example 2 is basically the same as that of Example 1. The difference is that there is only one group of cold medium outlets and inlets on the cylinder of Example 2 of this example, such as Figure 10 As shown, the cold medium can only flow in one direction.

[0058] Table 1 Comparison of the simple series connection between the full series plate and shell heat exchanger of the present invention and multiple traditional plate and shell heat exchangers

[0059]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap