Method for improving kinetic stability of high-stored-energy flywheel metal hub

A technology with high energy storage and stability, applied in the field of mechanical science, to achieve the effect of reducing assembly cooling time, simple method, and reducing the possibility of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention: the method for improving the dynamic stability of metal hub of high-energy storage flywheel, by changing the geometric dimension of the metal hub of high-energy storage flywheel, the natural frequency of metal hub is changed, thereby avoids the natural frequency of metal hub and its Resonance is generated due to the same working frequency; and a deflection moment is generated during the rotation of the hub to prevent the rim from falling off the hub and maintain its interference to improve the dynamic stability of the metal hub.

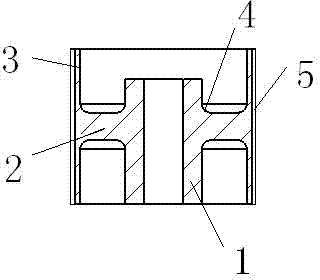

[0018] The structure of the high energy storage flywheel metal hub is as follows: figure 1 As shown, including the inner ring 1 and the outer ring 3, the web 2 is connected between the inner ring 1 and the outer ring 3, and the vertical length from the top to the center of the inner ring 1 is 1 / 2 smaller than the vertical length from the bottom to the center of the inner ring 1 ; The outer ring 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com