Transplanting machine front-and-back balancing system

A front-to-back direction and balance system technology, applied in the field of balance systems, can solve problems such as up and down bumps, insertion into the soil, inconsistent soil hardness, etc., and achieve the effect of uniform transplanting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

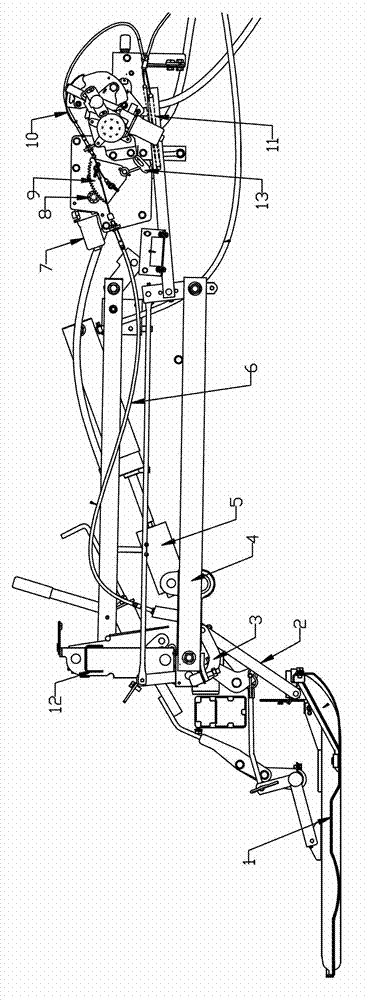

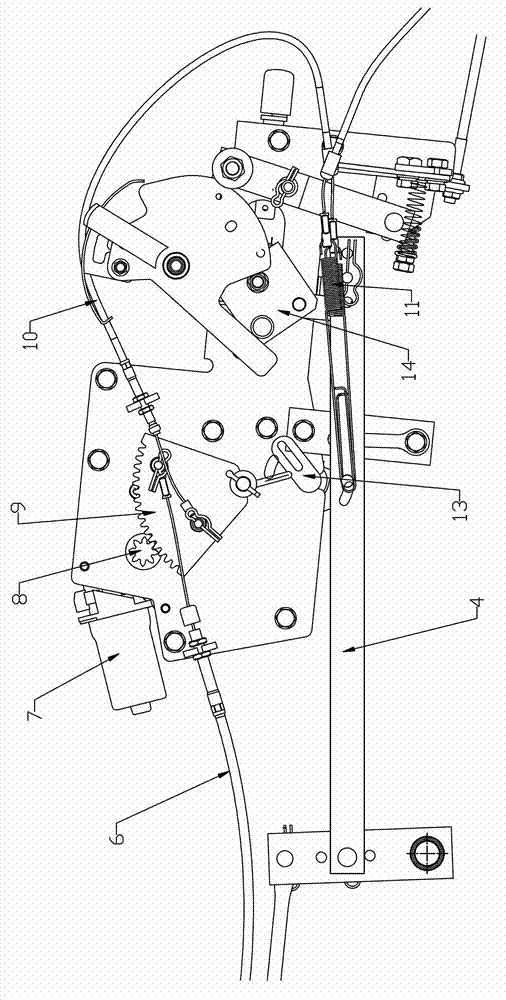

[0022] Such as figure 1 , figure 2 As shown, the present invention relates to a balance system for the front and rear directions of a rice transplanter, comprising a rice transplanter frame 12 and a central pontoon 1, the rice transplanter frame 12 is connected with the frame of the rice transplanter through a lifting mechanism, and the lifting mechanism includes a lifting cylinder 5 , the central pontoon 1 is rotatably connected with the rice transplanting frame, the center of gravity of the central pontoon 1 is on the front side of the transfer point between it and the rice transplanting frame, the front end of the central pontoon is connected with a pulling mechanism, and the pulling mechanism is connected with a longitudinal control The drive mechanism is connected, and the longitudinal control drive mechanism includes a drive motor 7. The drive shaft of the drive motor 7 drives the reduction device and is connected with a driving gear 8. The driving gear 8 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com