Cloth sole structure

A technology of cloth shoes and grid structure, which is applied in the direction of soles, footwear, insoles, etc., can solve the problems of difficult needle threading, affecting comfort, wet foot pads, etc., to ensure wearing comfort, good shape stability, and tightness less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

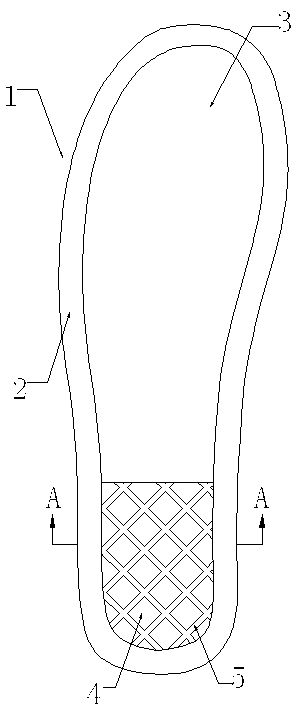

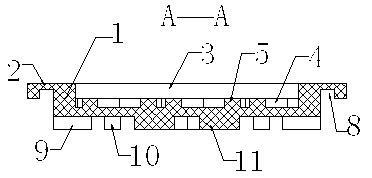

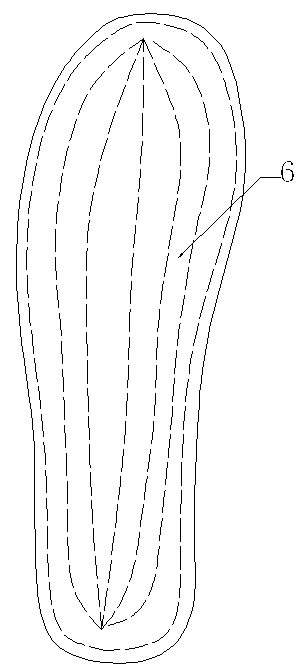

[0021] See figure, this cloth sole structure comprises sole 1, foot pad 6 and shoe pad 7, and the shape of their three outer edges is similar. An accommodating chamber 3 is provided on the upper surface of the sole 1, the outer edges of the accommodating chamber 3 and the insole 7 are similar in shape, and both of them have equal dimensions in the horizontal and vertical directions respectively, and the insole 7 is put into the accommodating chamber 3, After the insole 7 is put into the accommodating cavity 3 , the outer surface of the insole 7 is attached to the inner surface of the accommodating cavity 3 .

[0022] An annular coupling body 2 is provided at the mouth of the accommodation chamber 3 and is integrally connected with the wall body of the accommodation chamber 3 , and the coupling body 2 extends along the entire outer edge of the accommodation chamber 3 . The connecting body 2 protrudes horizontally toward the outside of the mouth of the receiving chamber 3 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com