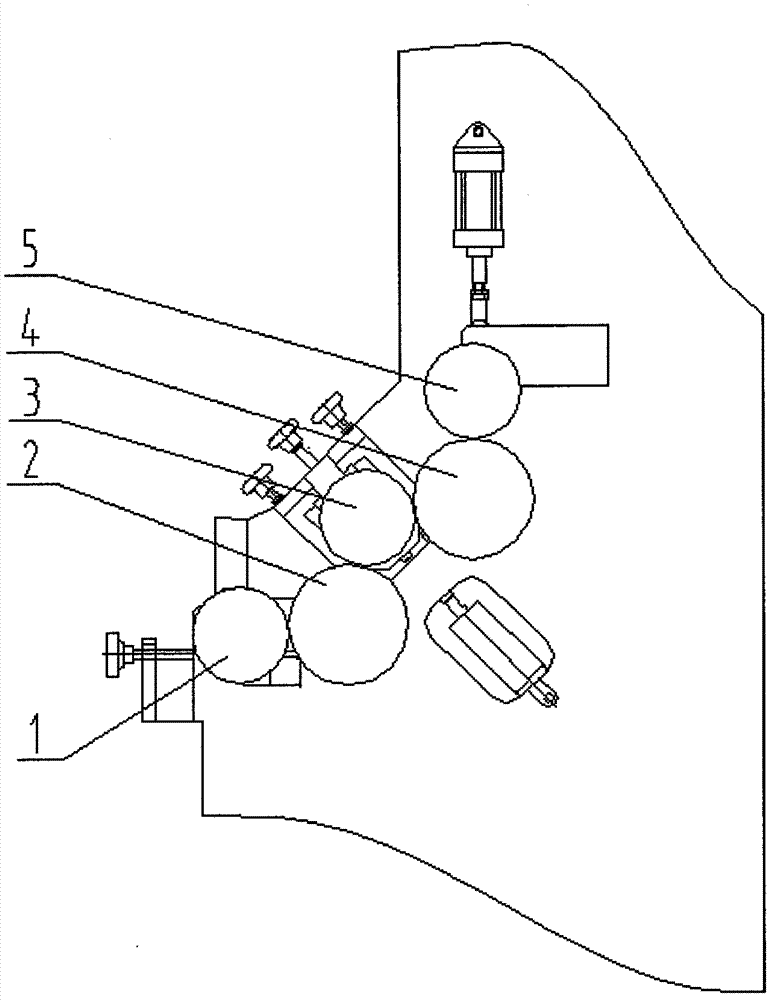

Precise multi-roller coating mechanism

A kind of roller coating and precise technology, applied in the device and coating direction of coating liquid on the surface, can solve the problems of too long adjustment time of metering roller gap, difficult to control the consistency of glue coating of composite film, white spot or bubble phenomenon, etc. To achieve the effect of precise and rapid control of the coating amount and the elimination of longitudinal microscopic glue line marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

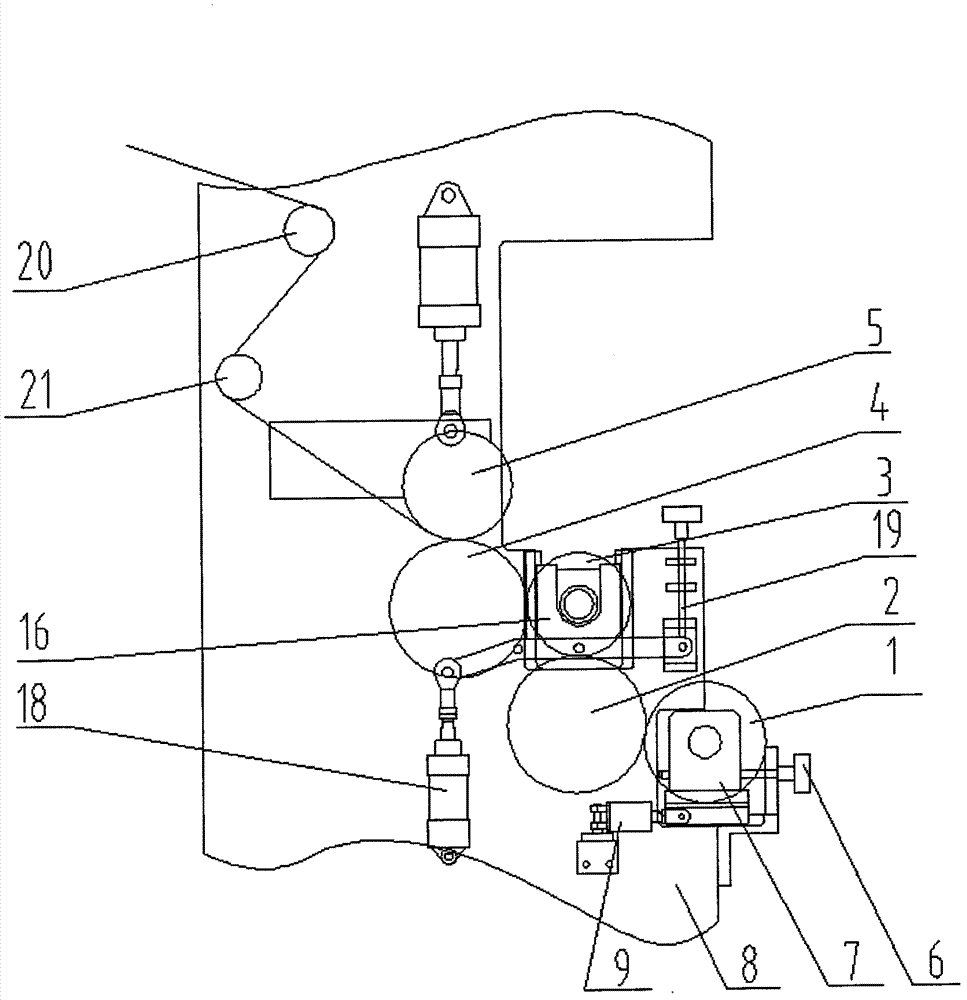

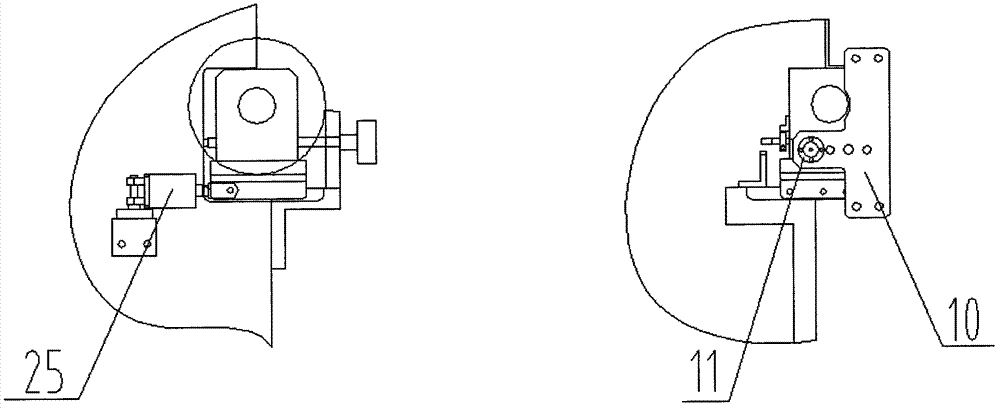

[0014] like figure 2 As shown, in the coating process, the substrate passes through the first transition roll 20 and the second transition roll 21 and enters between the coating rubber roll 5 and the coating steel roll 4 for coating, and the glue is placed on the metering roll 1 and the transfer steel roll. Between the rollers 2, the gap between the metering roller 1 and the transfer steel roller 2 is used to control the coating amount. image 3 The middle cylinder 25 is used to control the conversion of the metering roller 1 between the working position and the non-working position, and the positioning seat 10 and the positioning taper pin 11 are used to determine the working position of the metering roller 1, so that the rapid and accurate positioning of the metering steel roller can be realized.

[0015] like figure 2 , Figure 4 As shown, the transfer rubber roller is fixed on the bearing seat 26, the bearing seat 26 can slide horizontally on the sliding seat 16, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com