Method for determining torque of internal thread cold extrusion molding

A determination method and cold extrusion technology, applied to the determination of the forming torque of internal thread cold extrusion, in the field of internal thread cold extrusion processing, can solve problems such as few factors to consider and poor accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

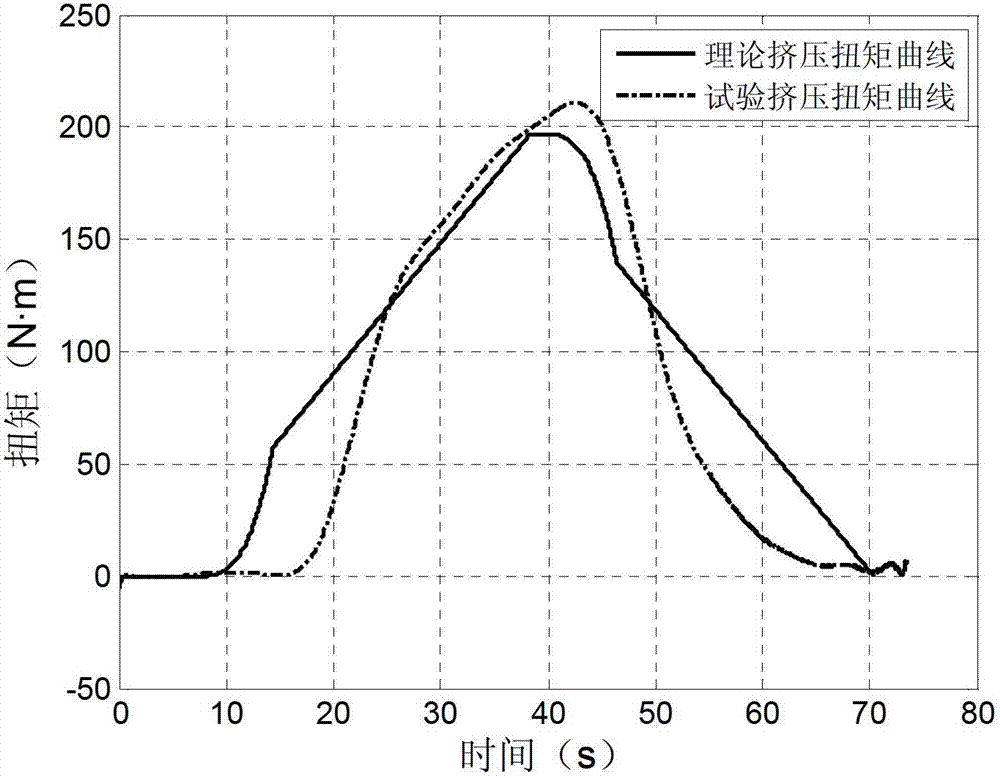

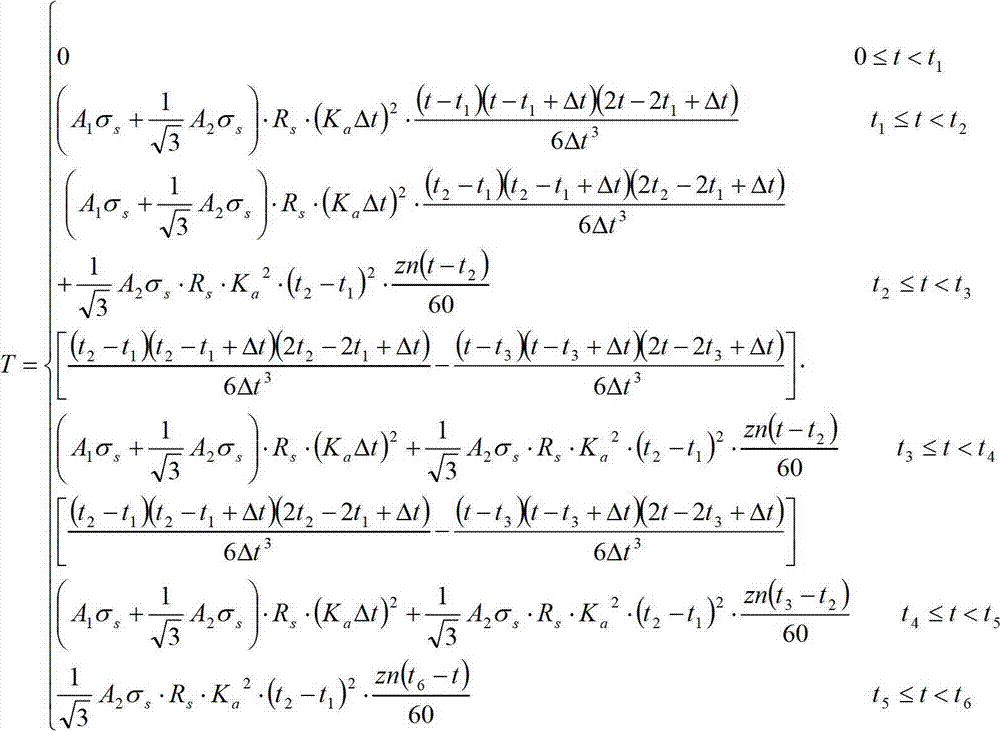

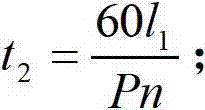

[0089] M35 high-speed steel extrusion taps are selected, and the surface is coated with TiN. The structure is a hexagonal closed conical tooth structure. The structural parameters of the extrusion taps are: the length of the extrusion taper (l 1 ) 9mm, correction part length (l 2 ) 15mm, extrusion cone angle 4°50', the amount of shovel back is 0.65mm. The test machine is a 6140 lathe. The test material is Q460 high-strength steel, and the mechanical parameters of the workpiece material at room temperature: tensile strength (σ b ) is 925MPa, the yield strength (σ s = σ 0.2 ) is 810MPa, elongation (δ 5 ) was 18.56%. Processing parameters: workpiece height 20mm, bottom hole diameter Φ21.25mm, machine speed 25r / min, using PDMS polydimethylsiloxane coolant to lubricate the extrusion tap, then the theoretical torque can be obtained through the mechanical model of formula 1 curve (see figure 1 ) and the maximum value of the theoretical torque (see Table 1).

[0090] Table 1...

example 2

[0093] M35 high-speed steel extrusion taps are selected, and the surface is coated with TiN. The structure is a hexagonal closed conical tooth structure. The structural parameters of the extrusion taps are: the length of the extrusion taper (l 1 ) 9mm, correction part length (l 2 ) 15mm, extrusion cone angle 4°50', the amount of shovel back is 0.65mm. The test machine is a 6140 lathe. The test material is 2A12 aluminum alloy, the mechanical parameters of the workpiece material at room temperature: tensile strength (σ b ) is 460MPa, the yield strength (σ s =σ 0.2 ) is 360MPa, elongation (δ 5 ) is 16%. Processing parameters: the height of the workpiece is 20mm, the diameter of the bottom hole is Φ21.25mm, the speed of the machine tool is 25r / min, and the extrusion tap is lubricated with PDMS polydimethylsiloxane coolant, the theory can be obtained through the mechanical model of formula 1 Maximum torque (see Table 2).

[0094] Table 2 Comparison of mechanical model calc...

example 3

[0097] M35 high-speed steel extrusion taps are selected, the surface is coated with TiN, and the structure is a hexagonal closed conical tooth structure. Structural parameters of extrusion tap: length of extrusion taper (l 1 ) is 9mm, corrected part length (l 2 ) is 15mm, extrusion cone angle It is 4°50', and the amount of shovel back is 0.65. The experimental machine tool is 6140 lathe. The test material is Q460 high-strength steel, and the mechanical parameters of the workpiece material at room temperature: tensile strength (σ b ) is 925MPa, the yield strength (σ s =σ 0.2 ) is 810MPa, elongation (δ 5 ) was 18.56%. Processing parameters: workpiece height 20mm, bottom hole diameters are Φ21.15mm, Φ21.20mm, Φ21.30mm, Φ21.35mm, machine speed 25r / min, using PDMS polydimethylsiloxane coolant to extrude taps Lubrication, the theoretical maximum torque can be obtained through the mechanical model of formula 1 (see Table 3).

[0098] Table 3 Comparison table between mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com