Plum blossom-shaped contact installing tool and plum blossom-shaped contact propeller

A plum-blossom contact and pusher technology, which is used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of spreading, dislocation of plum-blossom contacts, and uneven force on plum-blossom contacts, and achieve uniform force. , the effect of not easy to dislocate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

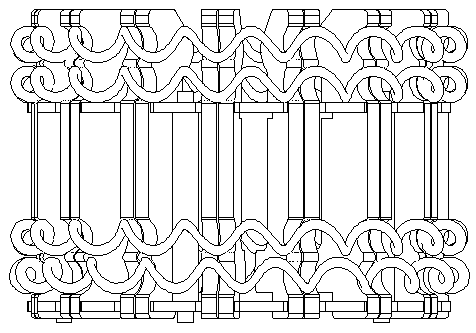

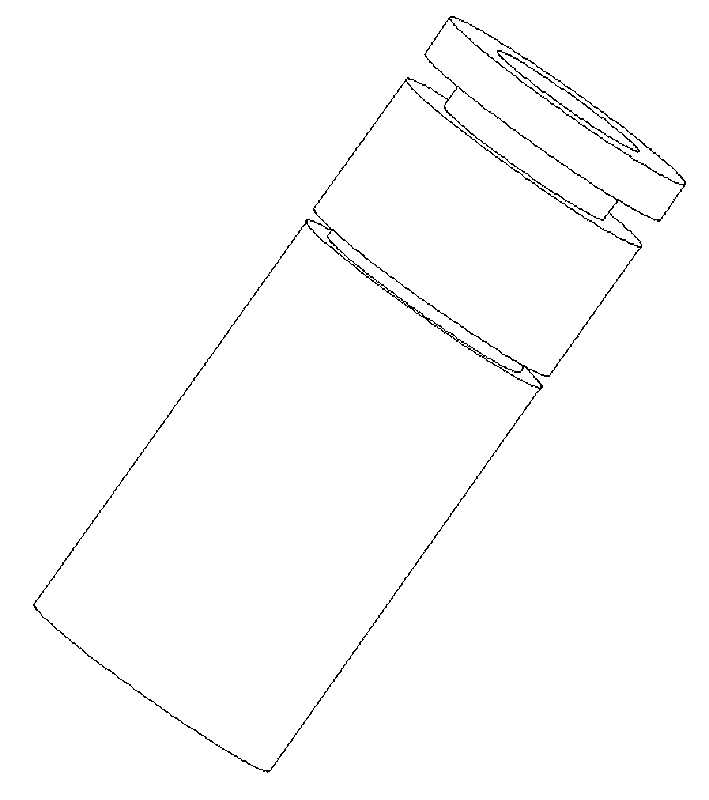

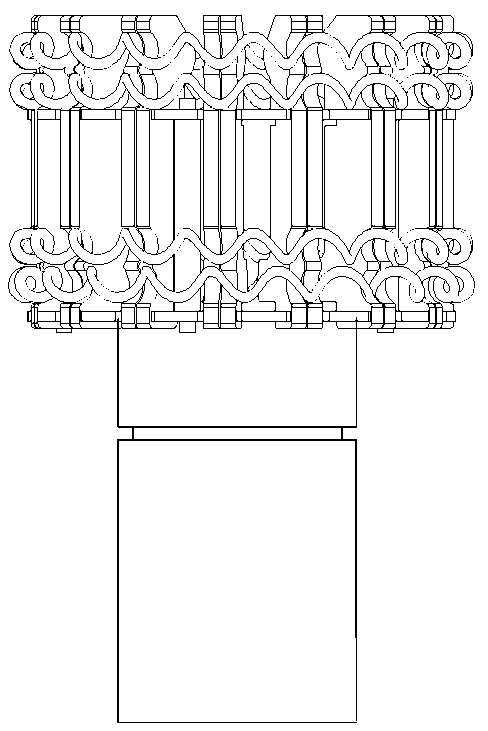

[0020] An embodiment of a plum blossom contact installation tool, such as Figure 4~Figure 5 As shown, it includes a guide body 1 with a tapered surface and a pusher 2. The pusher 2 includes a bottom plate 21 and a pressing plate 22 that moves up and down relative to the bottom plate 21 arranged above the bottom plate 21. The bottom plate 21 and the pressing plate 22 are connected. The up and down guide movement mechanism that is set, the up and down guide movement mechanism comprises the guide sleeve 24 that is arranged on the left and right sides of the positioning boss 23 on the upper surface of the base plate 21 and the position corresponding to the guide sleeve 24 on the lower surface of the pressing plate 22 is fixedly installed. The guide rod 25, the guide rod 25 is plugged and guided with the guide sleeve 24, and the lower surface of the pressing plate 22 is provided with a pushing surface for pushing the plum blossom contact. The upper surface of the bottom plate 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com