Hob type slicer

A slicer and hob-type technology, applied in metal processing and other directions, can solve problems such as difficult adjustment, poor appearance quality, inconsistent size and specifications, etc., to achieve the effect of ensuring continuity, smooth feeding and discharging, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

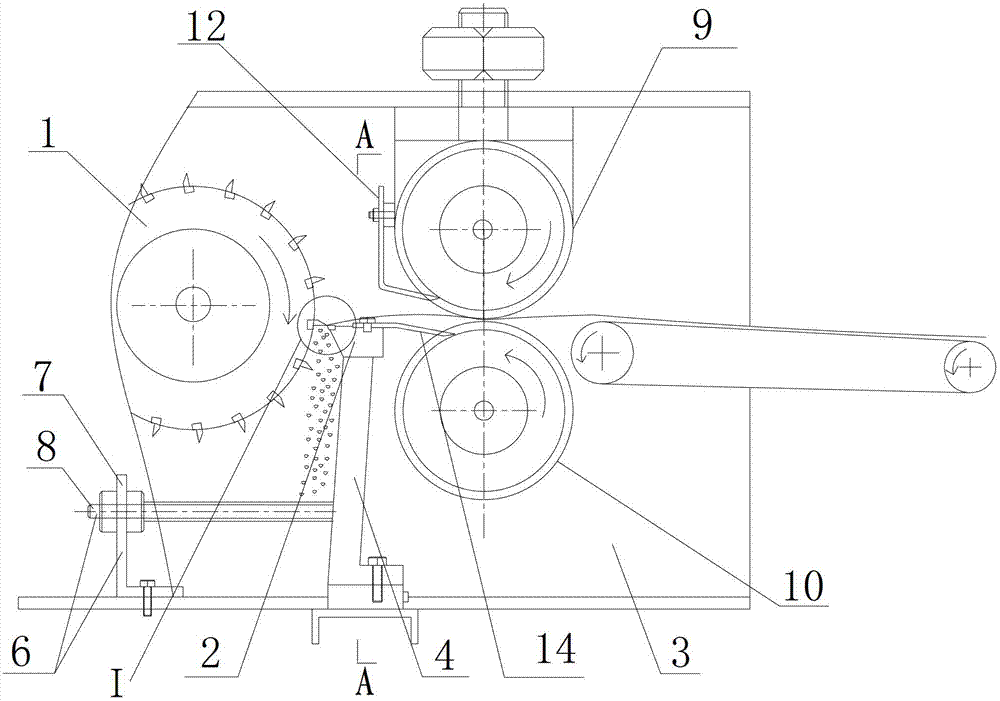

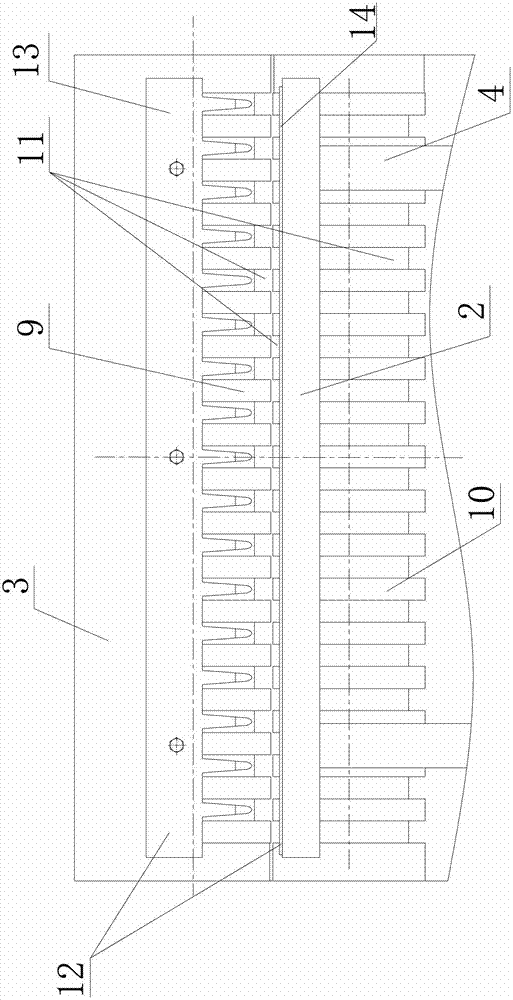

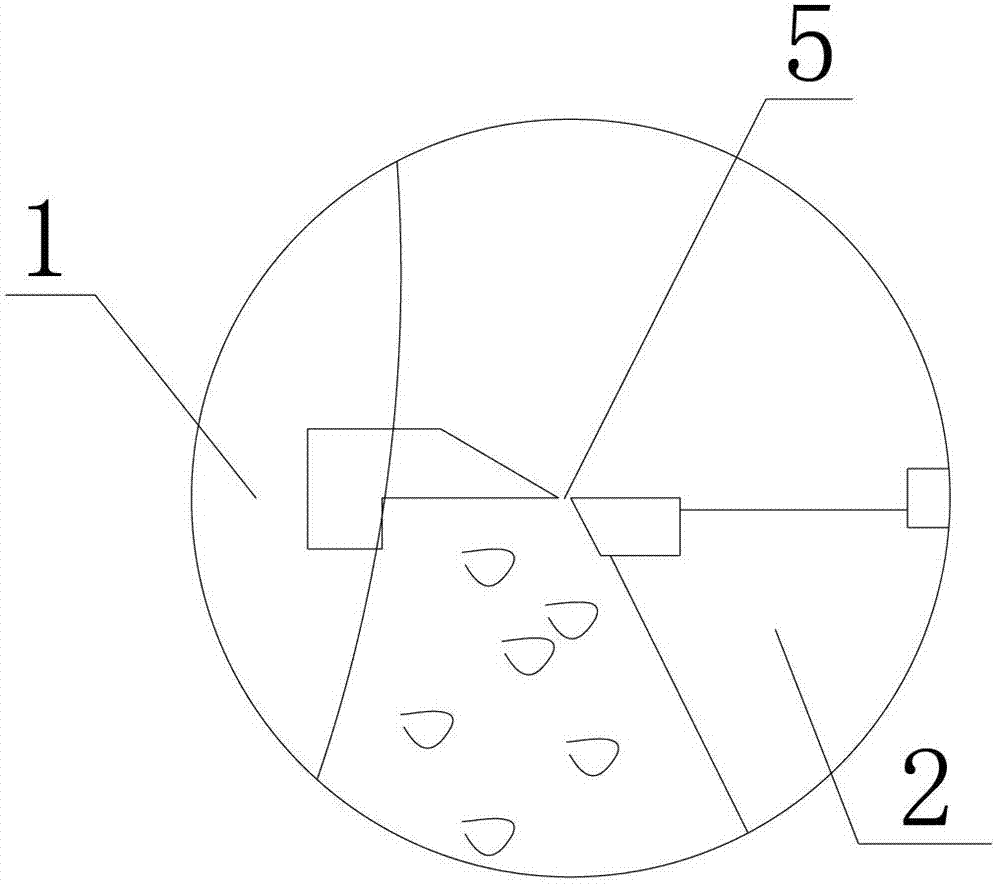

[0022] Such as figure 1 , figure 2 as well as image 3 Shown is a hob-knife slicer that can conveniently adjust the shearing gap between the bottom knife and the flying knife of the cross-cutting mechanism and maintain the shearing gap for a long time provided by the present invention. The hob slicer includes a cross-cutting mechanism consisting of a flying knife 1 and a bottom knife 2, the flying knife 1 is fixedly installed on the frame 3, the bottom knife 2 is installed on the frame 3 through the bottom knife frame 4, and the flying knife There is a shearing gap 5 between 1 and the bed knife 2, and also includes a bed knife quick adjustment mechanism 6, the shearing gap 5 between the fly knife 1 and the bed knife 2 is adjusted by the bed knife quick adjustment mechanism 6 through the bed knife holder 4 . In this way, in combination with the structural characteristics that the bottom knife 1 of the existing hob-knife slicer is installed on the frame 3 through the bed kni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com