High-speed double-clamping rotary type corrugated machine

A corrugating machine, high-speed technology, applied in the direction of mechanical processing/deformation, can solve the problems of reducing production efficiency and affecting the economic benefits of enterprises, and achieve the effect of reducing fan power, reducing air volume loss, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

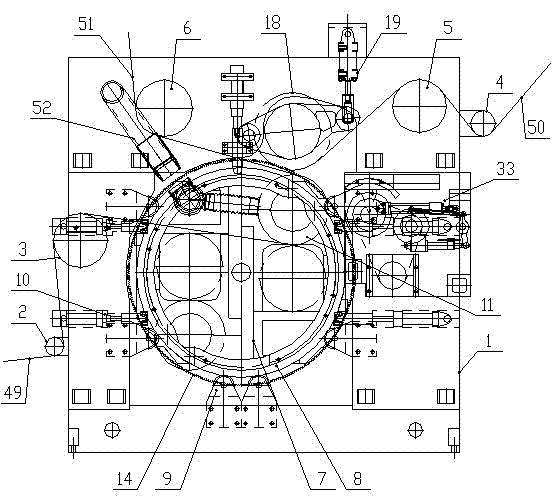

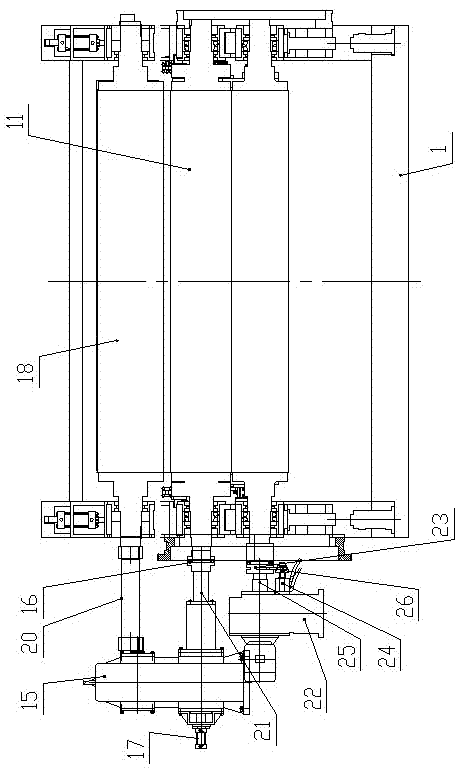

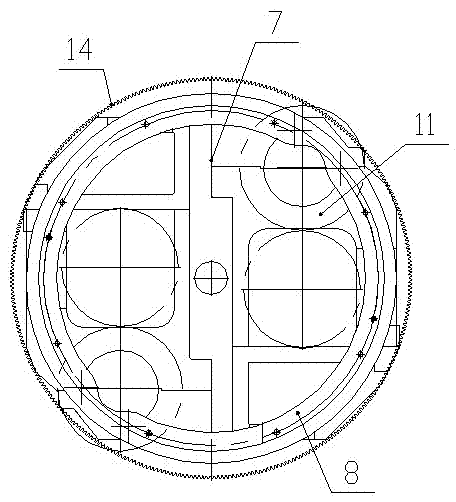

[0025] Such as Figure 1 to Figure 9 As shown, the high-speed double-card rotary corrugating machine of the present invention includes a frame 1, and the frame 1 is provided with a main power device, a base paper guide roll 2, a base paper preheating roll 3, a corrugating roll device, a gluing device 33, Paper guide roller 4, paper preheating roller 5, pressure roller device and corrugated paper preheating roller 6, the corrugating roller device includes a corrugating roller frame 7 whose center is rotatably connected to the machine frame, and two ends of the corrugating roller frame 7 are respectively provided with a Supporting ring 8, two supporting rings 8 are surrounded by supporting rollers 9 and locking mechanism 10 on the frame 1, corrugating roller frame 7 is provided with two pairs of corrugating rollers that are symmetrical about the line connecting the centers of the two supporting rings 8 11. One of the support rings 8 is connected with a rotary drive mechanism. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com