Production method of ultra-pure electronic grade phosphoric acid

A technology of electronic grade phosphoric acid and production method, applied in the field of phosphoric acid, can solve the problems of inconvenient control of reaction intensity and high energy consumption, and achieve the effects of saving process time and energy consumption, large effective contact surface, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples can better illustrate the present invention:

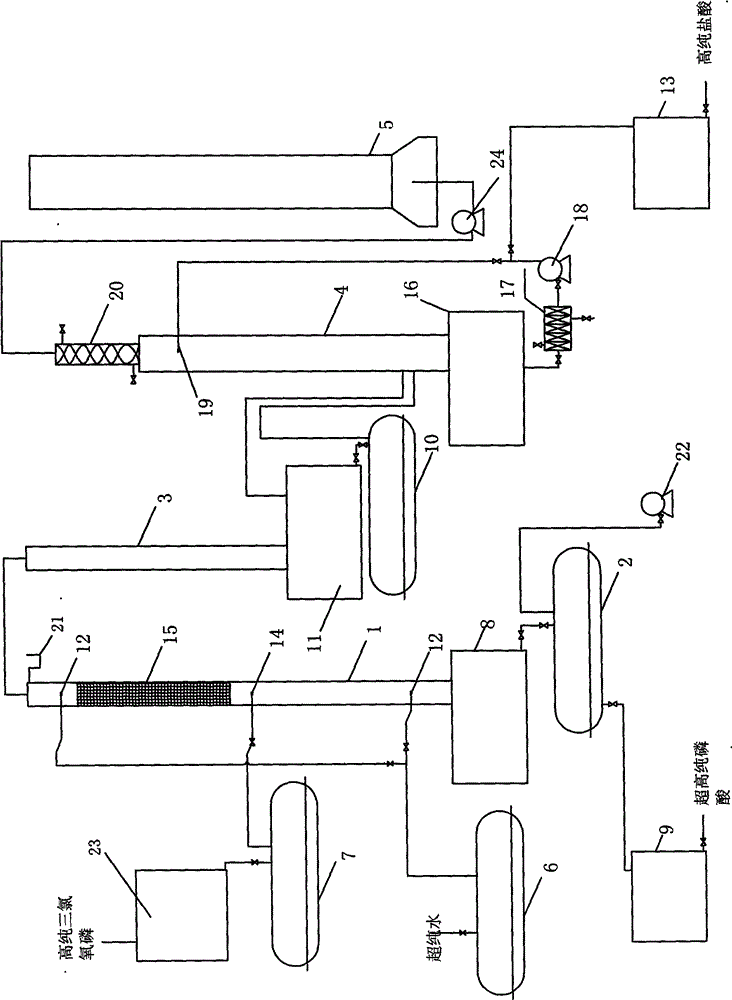

[0021] Production process such as figure 1 : (1) 100kg of high-purity phosphorus oxychloride with a mass fraction of 99.9999% is introduced into a high-purity phosphorus oxychloride steam generator, and the temperature of the phosphorus oxychloride steam generator is controlled in the range of 100°C to 107°C by means of electric heating, Make it generate a large amount of phosphorus oxychloride vapor and introduce it into the phosphoric acid generator for reaction; (2) introduce 50kg of high-purity water with a resistivity of 17.5MΩ or more into the steam generator, and control the temperature of the steam generator to 95°C~ 100°C, so that a large amount of water vapor is introduced into the phosphoric acid generator for reaction; (3) The mass ratio of water vapor and phosphorus oxychloride vapor entering the phosphoric acid generator is adjusted to 1:2 through the valve, and the upper part of the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com