Suspension type tin groove cooling method and apparatus thereof

A cooling method and hanging technology, which is applied in the field of cooling method and device in the high temperature area of the hanging tin bath, can solve the problems of high labor intensity, uneven cooling degree, and low product quality, so as to reduce manpower and uniformly cool the glass , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

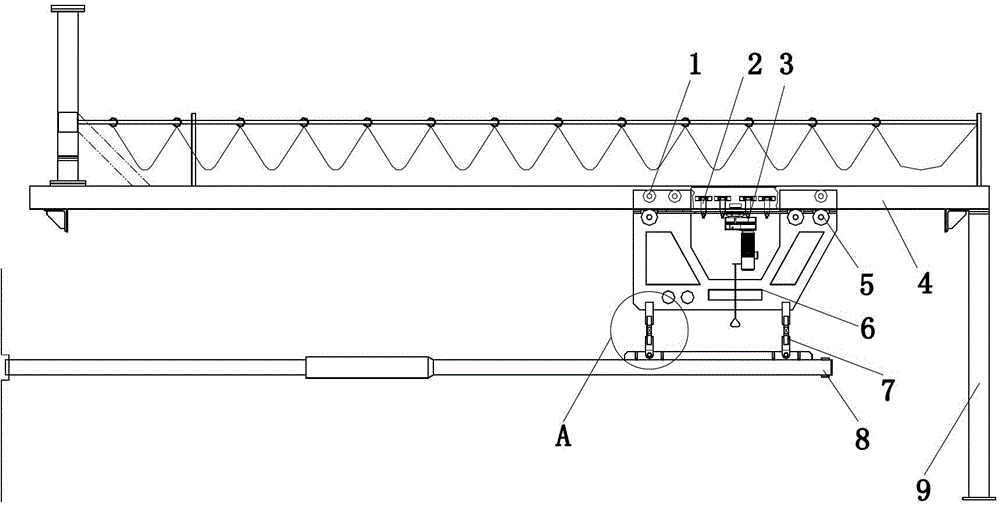

[0025] Example. A hanging tin bath cooling method is characterized in that: the high temperature area of the tin bath is cooled by a rack and pinion transmission tube cooler (also called a water bag) above the tin bath.

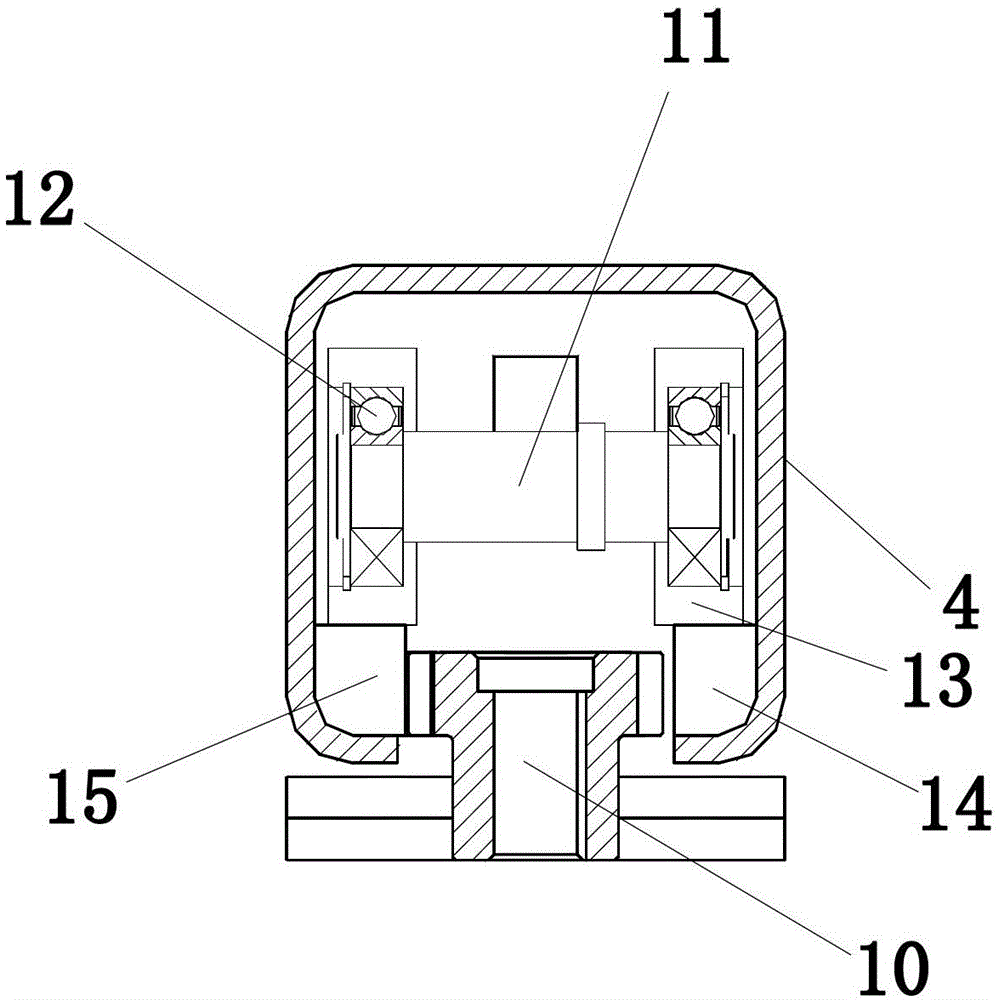

[0026] The method of the rack and pinion transmission tube cooler is to install racks and guide rails on both sides of the rectangular steel pipe, use a deceleration motor to drive the gears engaged on the racks to rotate, and limit the position through the guide rails, so that the connecting gears are connected. The trolley walks, thereby driving the tube cooler connected to the trolley.

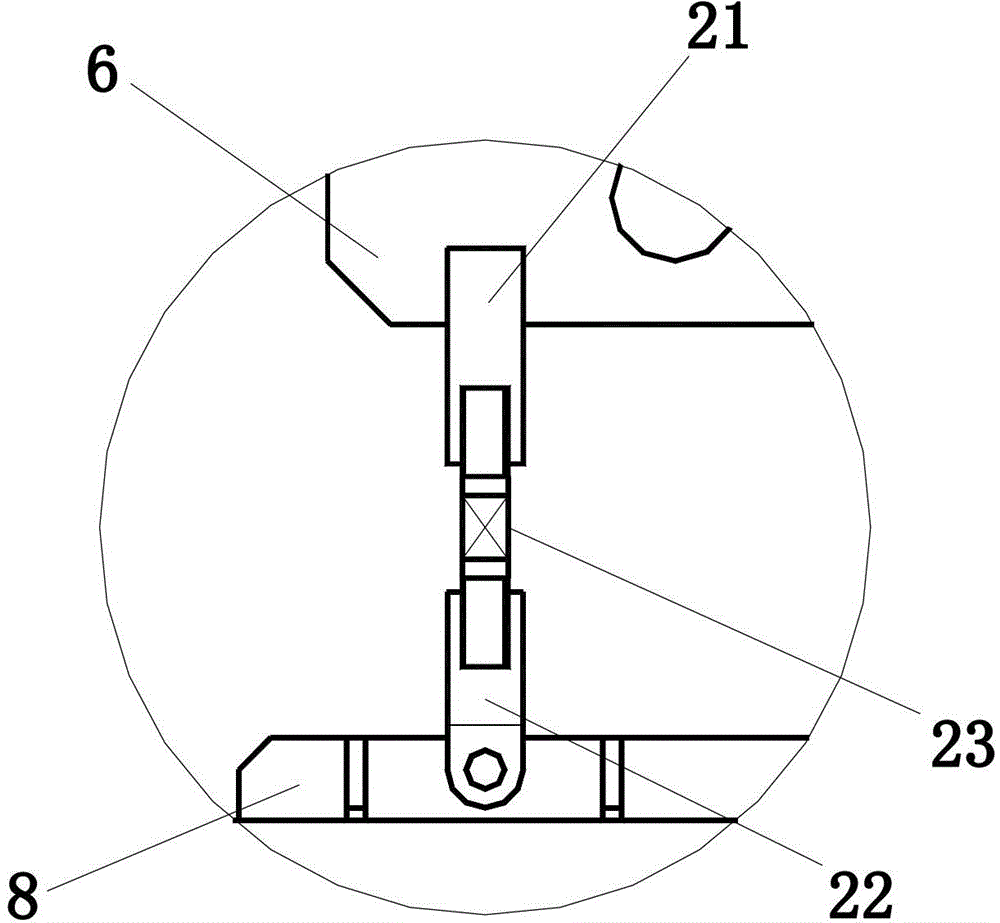

[0027] The trolley is connected to the tube cooler through two adjusting screws, and the adjusting screw adopts a left-hand thread at one end and a right-hand thread at the other end, so that the tube cooler can be adjusted up and down or horizontally.

[0028] The device for realizing the aforementioned hanging tin bath cooling method is constituted as follows Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com