Complete production device of energy-saving high-efficiency biomass fuel particles

A technology for biomass fuel and production equipment, applied in the direction of biofuel, waste fuel, fuel, etc., can solve problems such as increasing energy consumption, and achieve the effects of high energy utilization rate, convenient maintenance, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

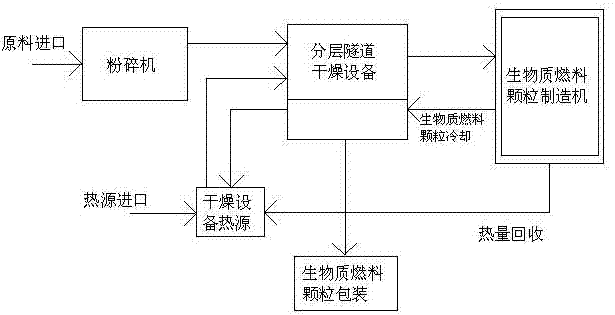

[0025] Such as figure 1 , 2 , 3, and 4 show a complete set of production equipment for energy-saving and high-efficiency biomass fuel particles, including pulverizers, drying equipment, granulators, and packaging equipment. The pulverizer is equipped with an energy storage flywheel device, which can be driven by a motor with a smaller power than ordinary pulverizers, so as to save energy.

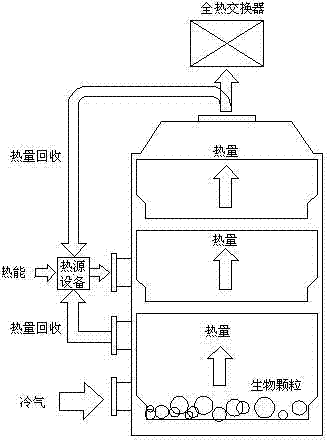

[0026] The drying equipment includes a drying device and a heat source.

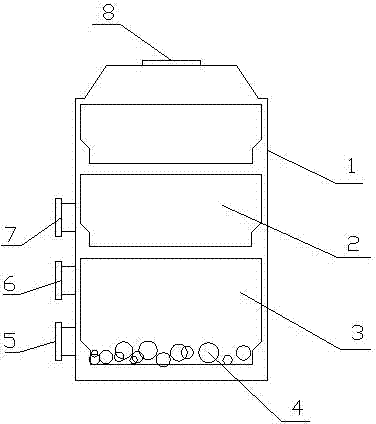

[0027] The drying device is a vertical tunnel layered structure, with several pairs of screw agitators inside, a material inlet at the top of the drying device, and a material outlet at the lower end. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com