Green self-cleaning super-hydrophobic oleophobic coated fabric

A coated fabric, self-cleaning technology, applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the unmentioned, waterproof and moisture-permeable coated fabric does not have the function of self-adaptive adjustment of water and oil stains, unmentioned self-adaptive Adjust the function of green self-cleaning, super hydrophobic and oil-repellent coating fabrics, etc., to achieve the effect of reasonable structure and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

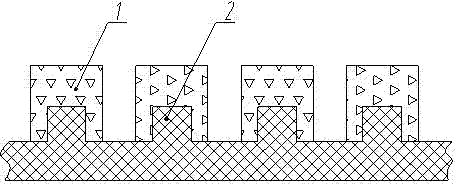

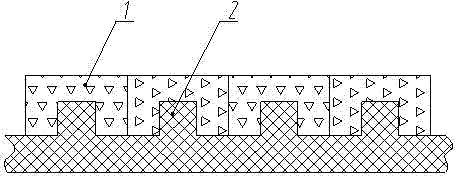

[0020] A green self-cleaning super-hydrophobic and oil-repellent coated fabric, including a base fabric, one side of the base fabric is formed by a plurality of identical rectangular protrusions 2 evenly arranged at a certain interval, and the other side of the base fabric is a planar structure, The entire surface of the rectangular protrusion on one side of the base cloth is coated with the liquid-swellable coating 1 and cured by drying.

[0021] The coating is formed by mixing nano-scale titanium dioxide and bentonite with photocatalytic function, wherein nano-scale titanium dioxide accounts for 30-70% (Example 30, 50%, 70%), and bentonite accounts for 30-70% (Example 30, 50% %, 70%).

[0022] During the use of this product, when a certain area or the entire outer surface of the product is in contact with water, oil, etc., the structure of the coating agent on the base cloth is as follows: figure 1 As shown, that is, there is a gap between the coating agents on adjacent pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com