Pipeline drainage structure

A drainage structure and pipeline technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of reduced runoff, small diameter of the drainage cover, flooding Jinshan, etc., to reduce the probability of blockage, reduce Labor cost, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

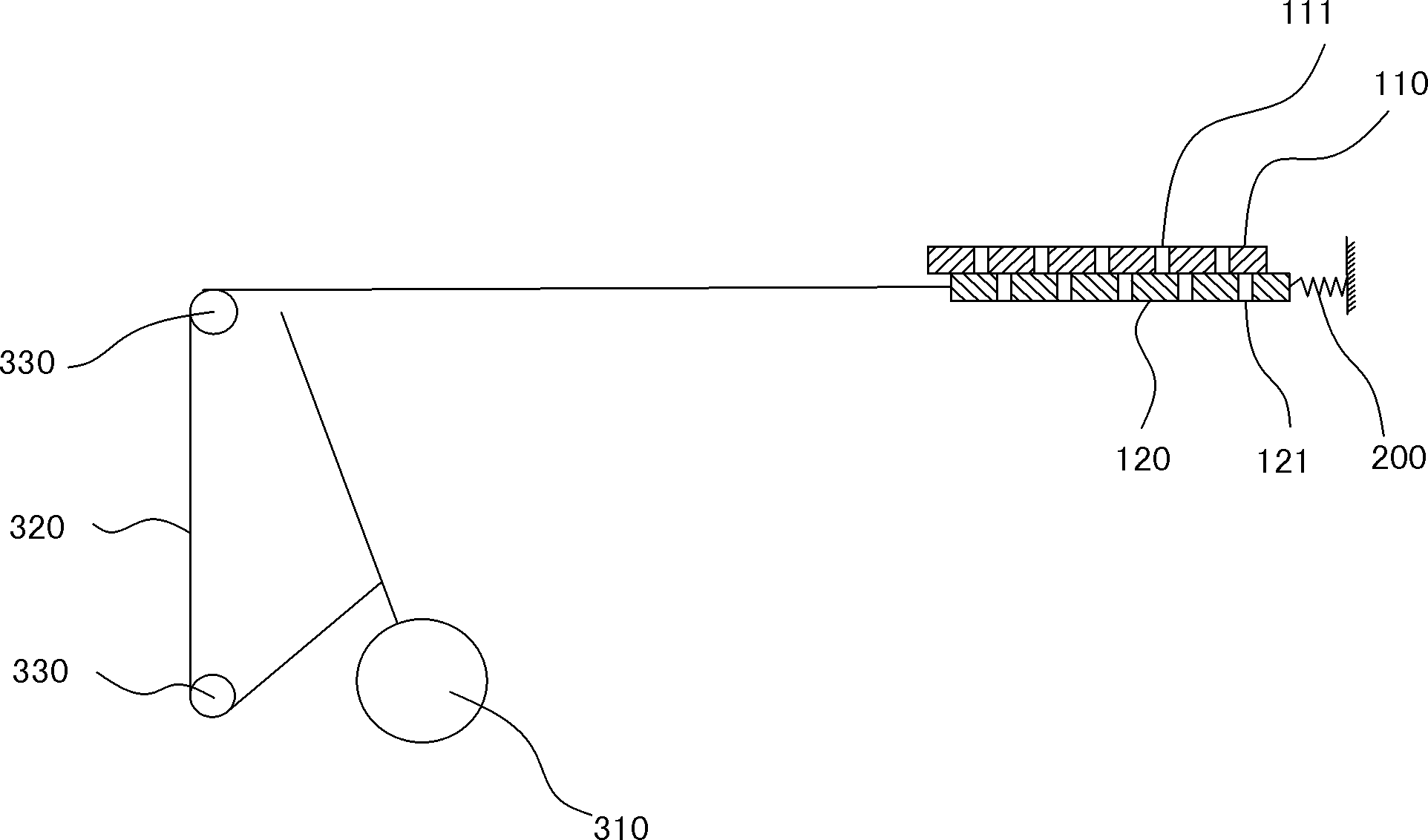

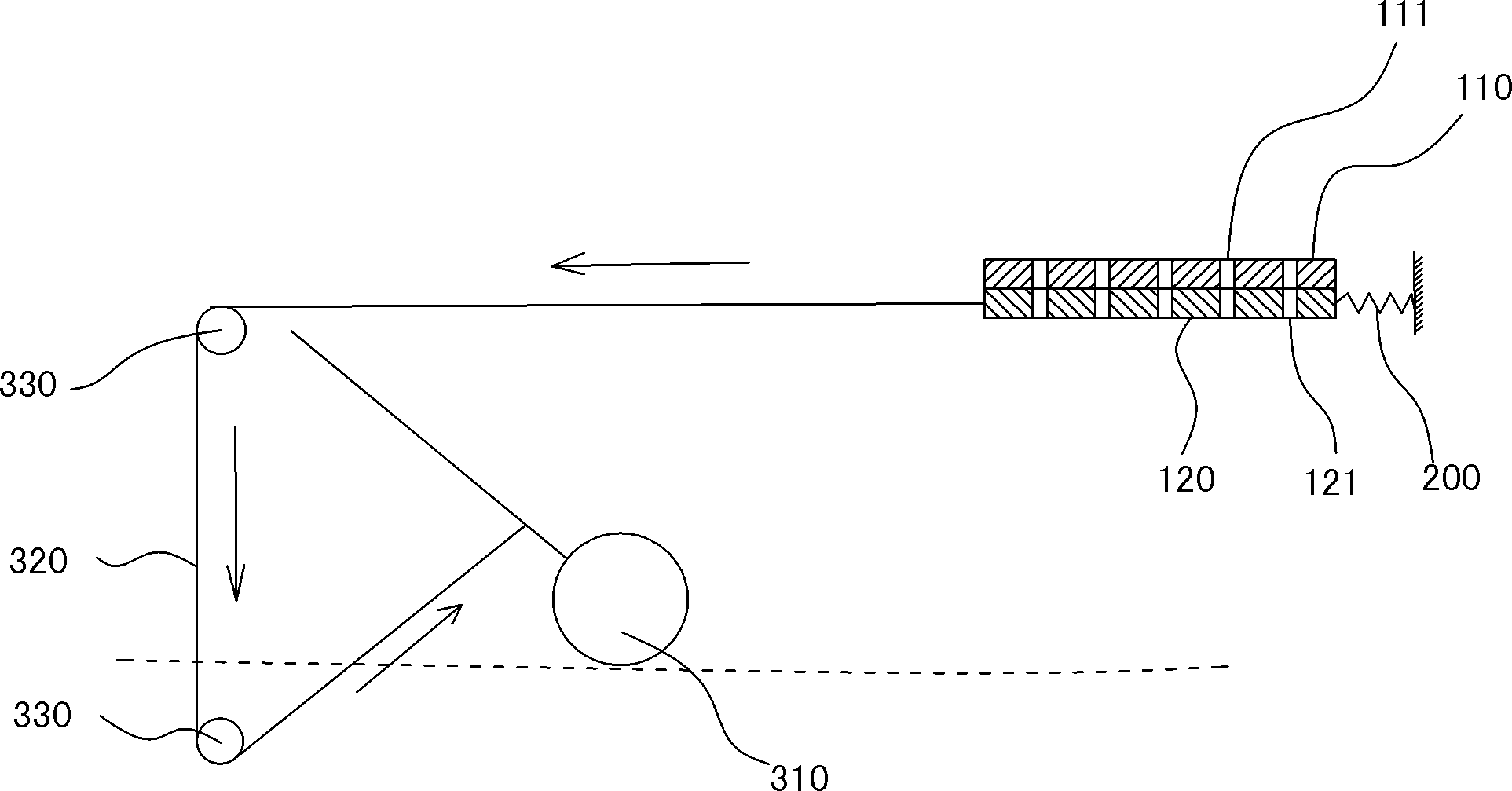

[0024] see figure 1 and 2 , a drainage structure applied to sewer pipes, comprising a baffle mechanism and a floating ball pulling mechanism for driving the baffle mechanism to open.

[0025] The baffle plate mechanism includes a fixed cover plate 110 and a movable cover plate 120, and a plurality of drain holes (111, 121) are arranged at intervals on the fixed cover plate and the movable cover plate, and the drain holes 111 on the fixed cover plate are connected with those on the movable cover plate. The drainage hole 121 is corresponding. The diameter of the drainage holes is 2cm-4cm, and the distance between adjacent drainage holes is 3cm-6cm. The fixed cover and the movable cover are stacked up and down, and the positions of the drain holes on the fixed cover and the drain holes on the movable cover are interlaced (such as figure 1 shown). One side of the movable cover is connected with the elastic return device 200 (a spring is used in this embodiment), and the other ...

Embodiment 2

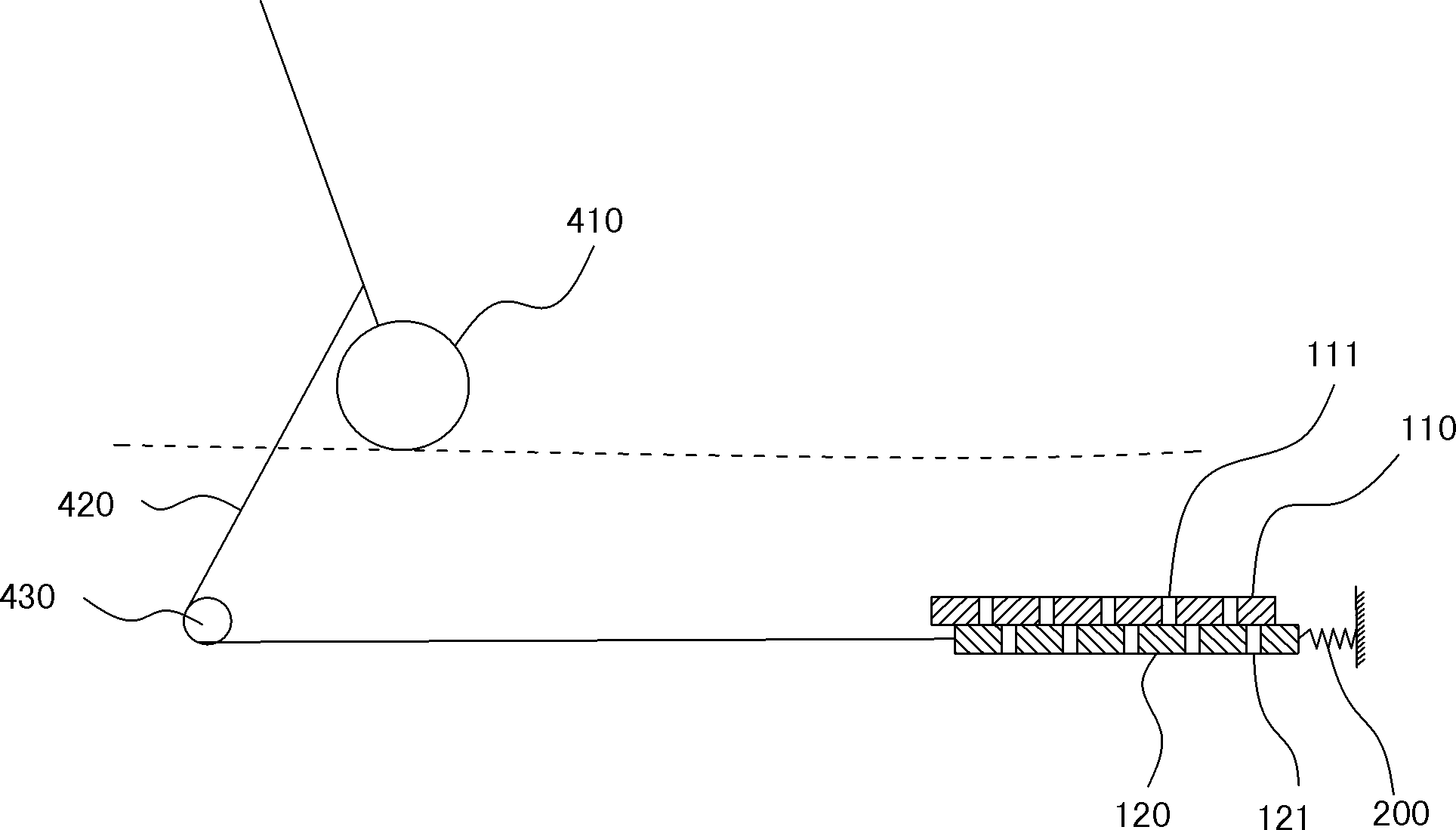

[0029] see image 3 and 4 , a drainage structure applied to rainwater pipes, comprising a baffle mechanism and a floating ball pulling mechanism that drives the baffle mechanism to open.

[0030] The baffle plate mechanism includes a fixed cover plate 110 and a movable cover plate 120, and a plurality of drain holes (111, 121) are arranged at intervals on the fixed cover plate and the movable cover plate, and the drain holes 111 on the fixed cover plate are connected with those on the movable cover plate. The drainage hole 121 is corresponding. The diameter of the drainage holes is 2cm-4cm, and the distance between adjacent drainage holes is 3cm-6cm. The fixed cover plate and the movable cover plate are stacked together up and down, and the positions of the drain holes on the fixed cover plate and the drain holes on the movable cover plate are interlaced. One side of the movable cover is connected with the elastic return device 200 (a spring is used in this embodiment), and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com