Modeling ceiling fixing structure

A technology for fixing structures and ceilings, applied in building components, building structures, buildings, etc., can solve the problems of easy cracks at the corners of ceilings, insufficient structural firmness, and affect the appearance, so as to avoid easy deformation and cracking, and is conducive to fixing and increasing. The effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

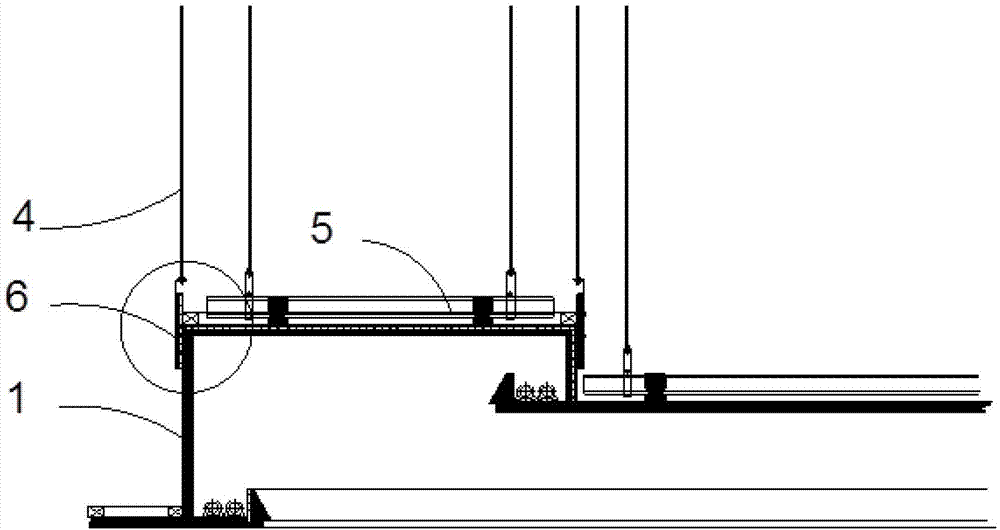

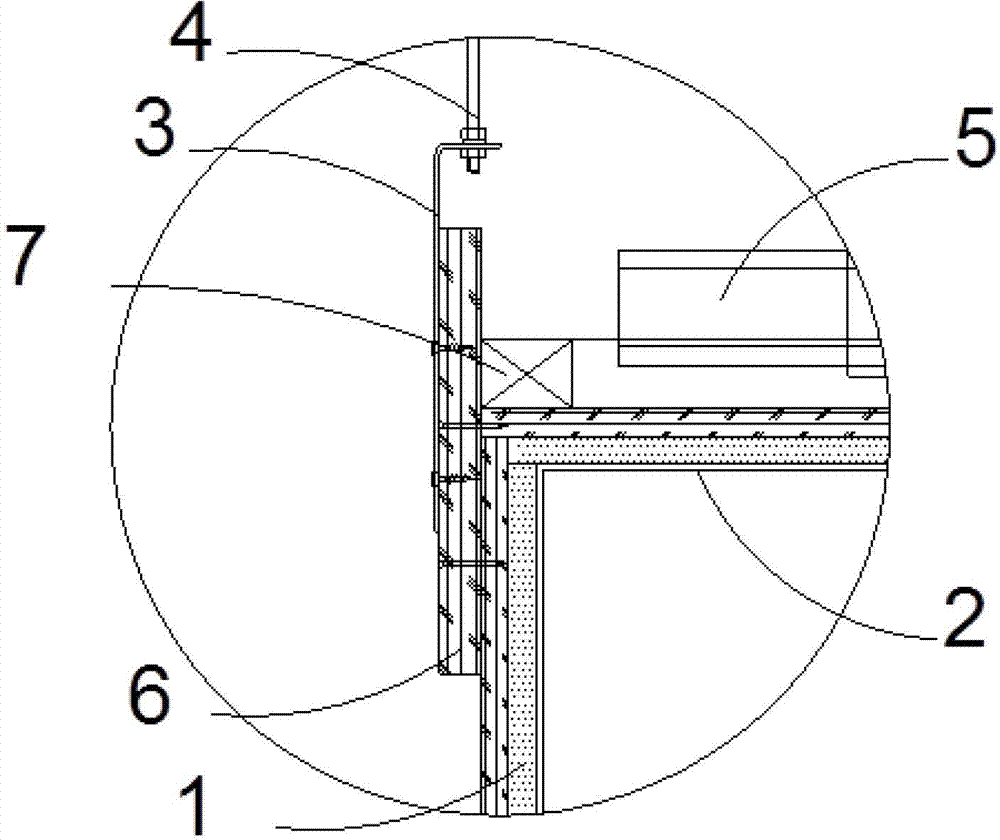

[0014] Such as figure 1 As shown, the shaped ceiling adopts the shaped vertical plate 1 and the shaped flat plate 2, and the shaped ceiling is fixed to the floor through the ceiling keel 5 and the suspender 4 hanging parts 3. Such as figure 2 As shown, the reinforcement board 6 is fixed on the back of the molding vertical board 1, the ceiling hanger 3 is fixed on the reinforcement board 6, and at the same time, the reinforcement board 7 is fixed on the back of the molding board 2, and the reinforcement board 7 and the reinforcement board 6 are in the shape Standing plate 1 and molding plate 2 corners are fixed.

[0015] The construction steps of the fixed structure of the modeling ceiling: firstly process the ceiling modeling vertical plate 1 and the modeling flat plate 2 according to the size of the design drawing; then fix the modeling vertical plate 1 and the modeling flat plate 2 according to the designed angle; Reinforcing plate 6 and reinforcing wooden frame 7; fix re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com