Fastener type steel pipe scaffold framework support applicable to steel reinforced concrete beam

A technology for concrete beams and concrete-filled steel tubular columns, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as hidden safety hazards, safety accidents, and conservativeness, and achieve structural safety and stability. , economical and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

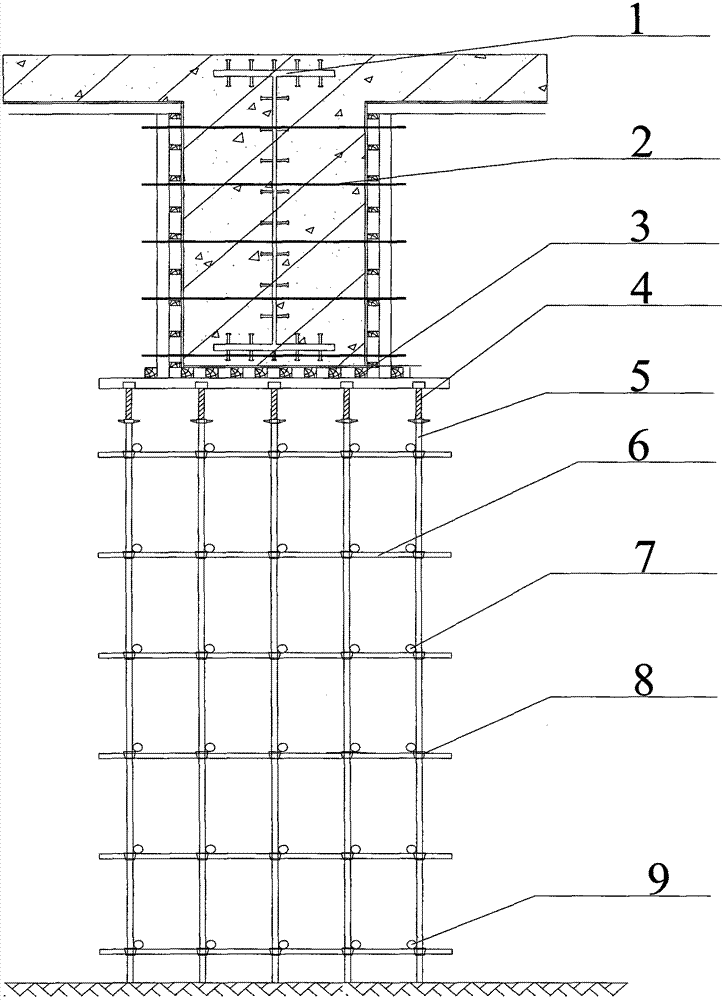

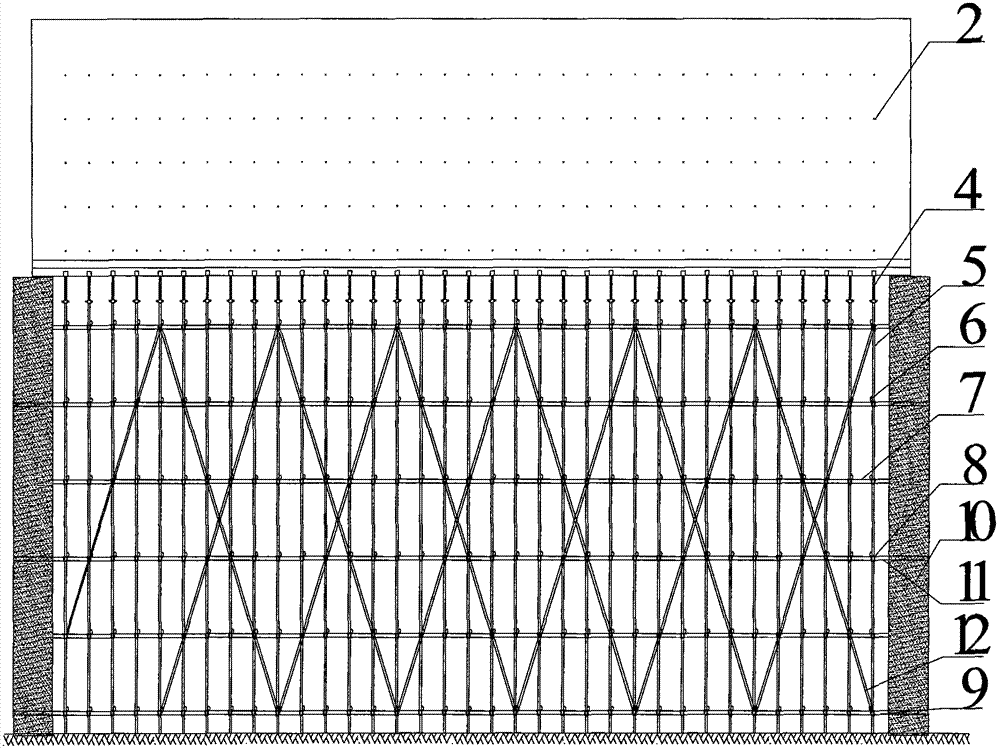

[0036] Such as figure 1 and figure 2 As shown, the fastener type steel pipe scaffold formwork bracket suitable for steel concrete beams, the bracket includes a vertical rod 5, a longitudinal horizontal rod 7, a horizontal horizontal rod 6 and a scissors brace 12, and is characterized in that: vertical rods, longitudinal horizontal rods, horizontal Both the horizontal bar and the scissors brace are made of Φ48×3.5 steel pipes, and the joints are connected by 8 malleable iron fasteners. The support has 34 spans in the vertical direction and 4 spans in the horizontal direction. The vertical distance between the vertical poles is 0.6m, the horizontal distance between the vertical poles is 0.6m, the bottom horizontal horizontal pole is the horizontal sweeping pole, the bottommost vertical horizontal pole is the vertical sweeping pole 9, the horizontal sweeping pole is located under the vertical sweeping pole, and the horizontal sweeping pole reaches the ground The distance is 0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com