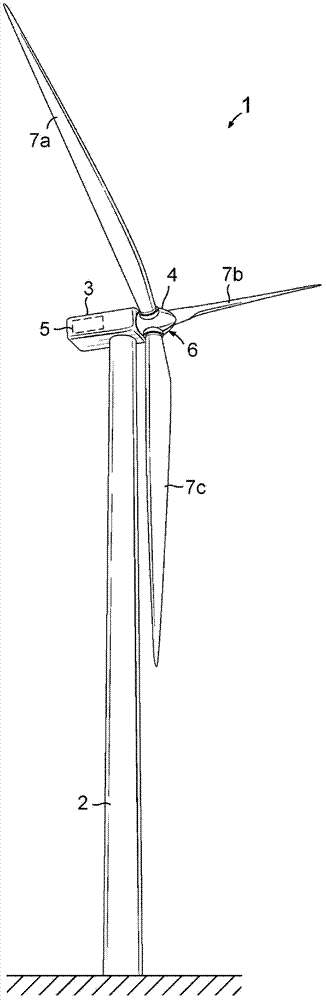

Methods of manufacturing wind turbine blades

A technology of wind turbine blades and recesses, which is applied to the support elements of blades, wind power engines, engine manufacturing, etc., and can solve time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

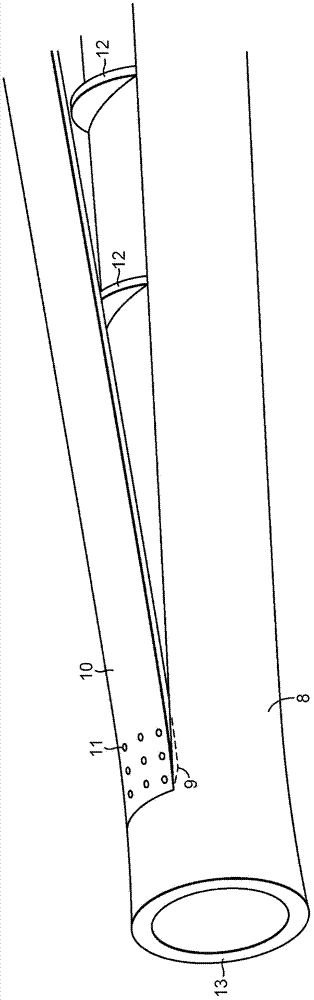

[0033] refer to figure 2 An elongated spar 8 of a wind turbine rotor blade is formed by winding a length of fiber of a suitable material, eg glass, around a mandrel, such elongated spar being formed with a recess 9 after completion of the winding process. An elongated web 10 is attached within the recess 9 of the spar 8 by using a combination of adhesive and an array of pins 11 . A plurality of spacer elements 12 may be connected between the spar 8 and the additional web 10 to provide support for the additional web 10 . The root end 13 of the spar 8 (on the left hand side of the figure) is attached to the central hub of the wind turbine. The part of the spar from the root end up to a distance therefrom is referred to herein as the root end, in which, as described above, the spar has a circular cross-section with a transition from circular to rectangular the section area of .

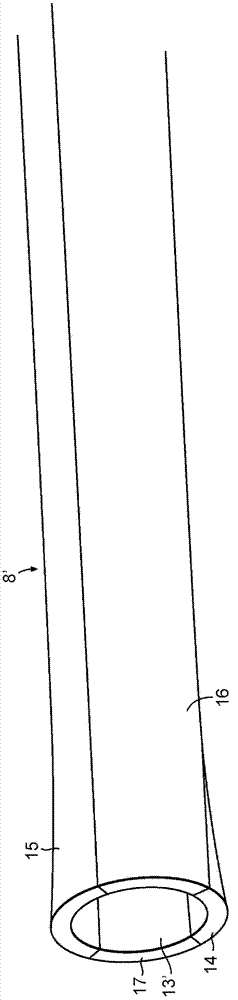

[0034] image 3 A quarter-part elongated spar 8' is shown, which is similar to figure 2 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com