Bearing vibration measurement machine

A vibration measuring machine and bearing technology, used in mechanical bearing testing, measuring devices, vibration testing and other directions, can solve the problems of insufficient test points, waste of labor, low efficiency, etc., to achieve rich test results, save labor, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

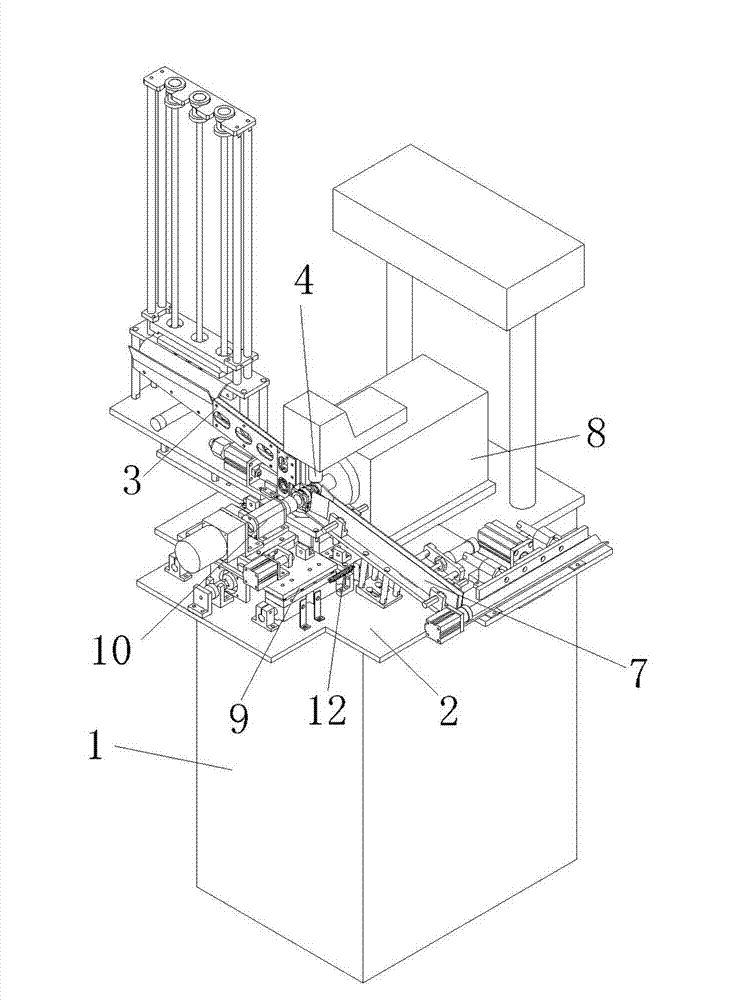

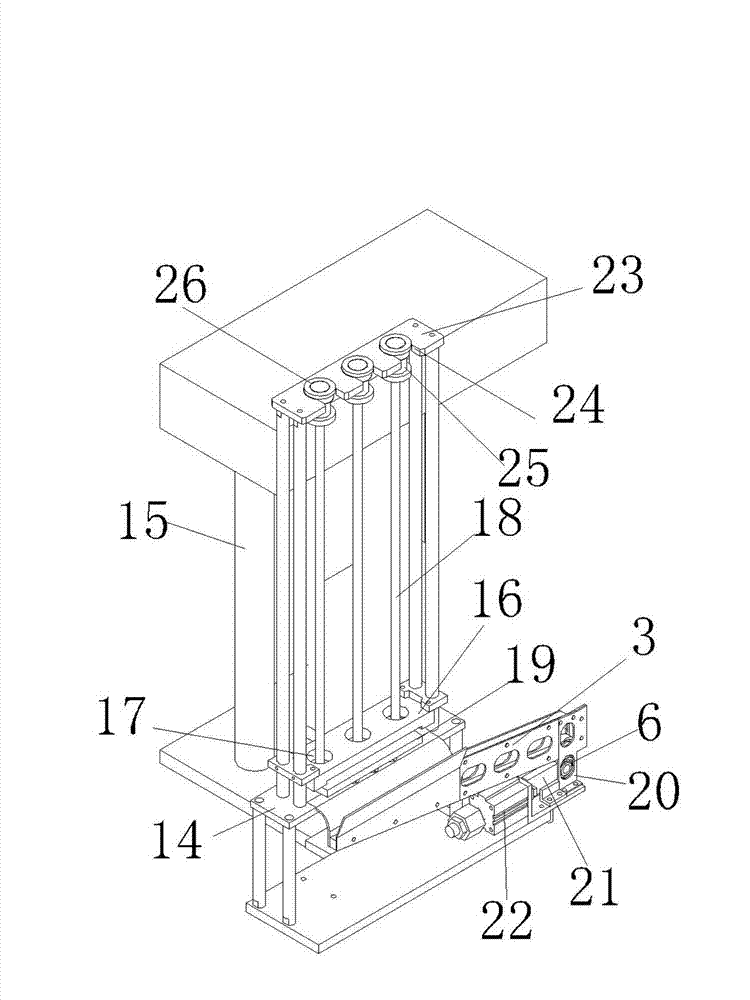

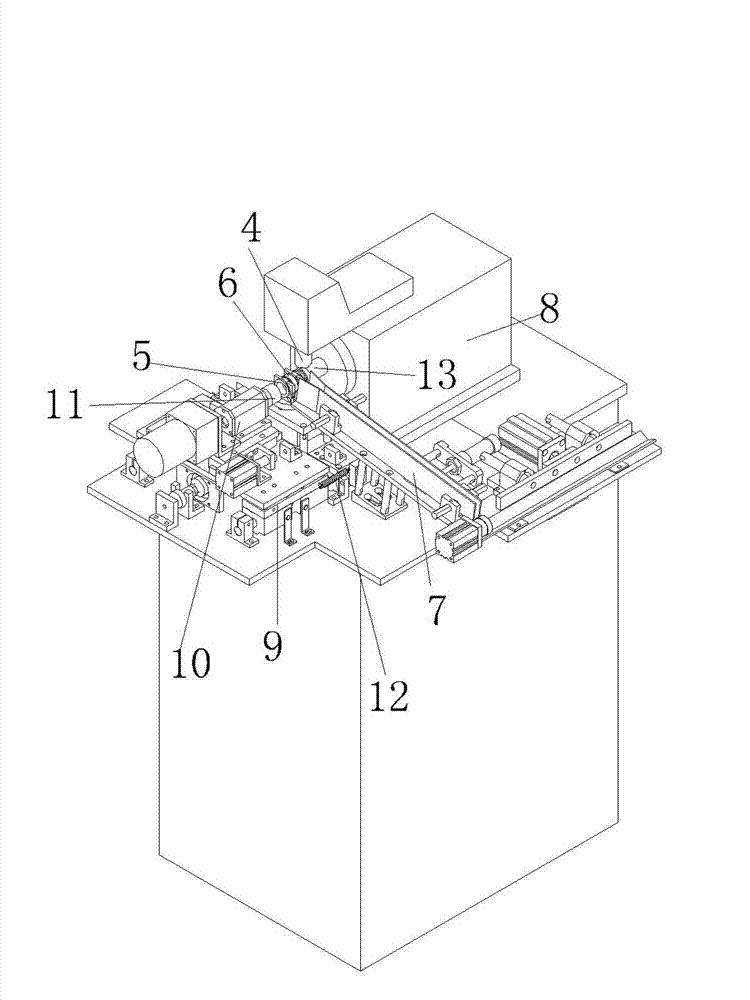

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] refer to figure 1 , figure 2 , image 3 , a bearing vibration measuring machine, including a frame 1, the frame has a workbench 2, and also includes a raceway 3 adapted to the bearing when it is erected, a material rack for placing materials, and a material rack located on the Above the vibrating rod 4, the raceway 3 is inclined from top to bottom and is arranged on the workbench 2, and a rotating body 5 is arranged in the described material rack, and the rotating body 5 has a In the interlayer containing the bearing 6 , the vibrating rod 4 is facing the interlayer of the rotating body 5 . In this embodiment, a blanking interlayer 7 is also provided behind the interlayer of the rotating body.

[0024] A slidable slide table 8 is provided on the workbench, and the described rack and the vibrating rod 4 are arranged on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com