Concrete guard fence machining equipment and using method thereof

A processing equipment and concrete technology, which is applied in the field of concrete guardrail processing equipment, can solve the problem that the bottom of the concrete guardrail is easily damaged by freezing, and achieve the effects of less water absorption, low porosity and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

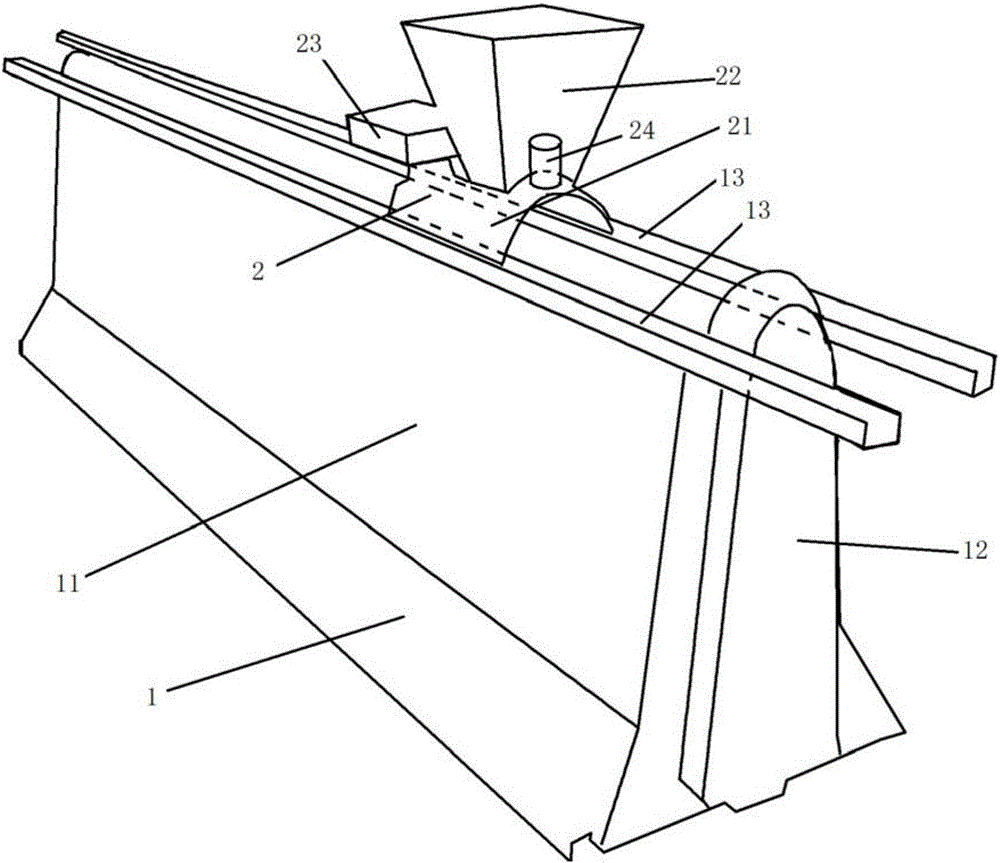

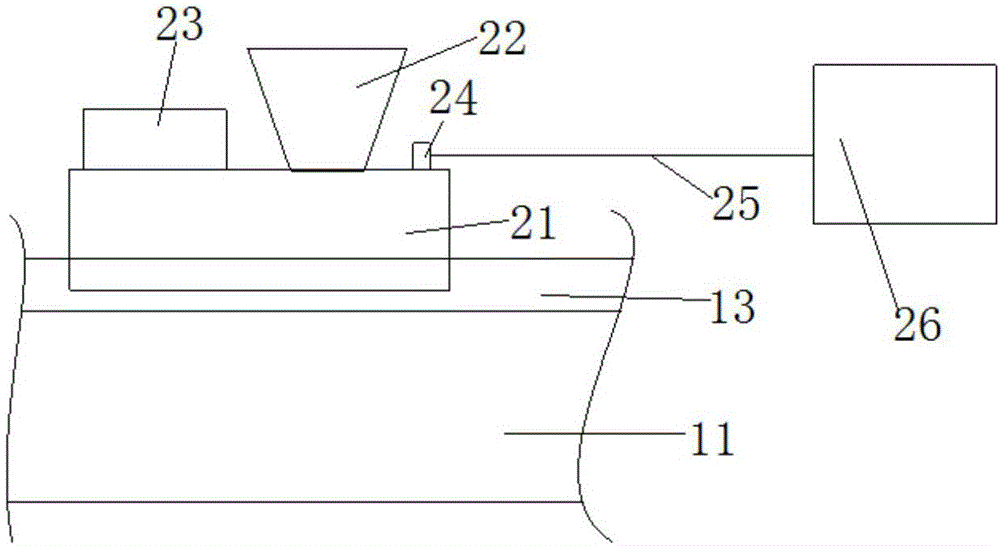

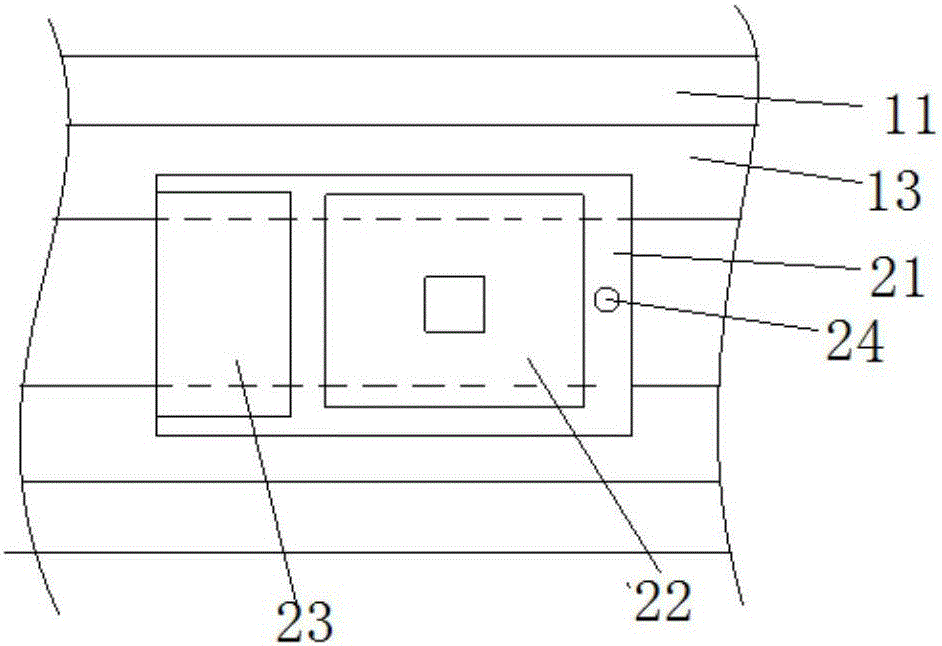

[0033] like figure 1 , figure 2 As shown, a kind of concrete guardrail processing equipment of the present invention comprises mold 1 and vibratory feeding device 2, and mold 1 is the concrete guardrail mold 1 commonly used in prior art, comprises two side walls 11 and two end walls 12, two The side wall 11 is arranged at two trapezoidal waists, and the two end walls 12 are respectively arranged at both ends of the side wall 11 and connected with the ends of the side wall 11, and guide rails 13 are respectively arranged on the tops of the two side walls 11, Two guide rails 13 are arranged in parallel, and the vibrating feeding device 2 is movably arranged on the guide rail 13. The vibrating feeding device 2 includes a base 21, a hopper 22 and a vibrating device 23. The base 21 matches the shape of the guardrail top, and the base 21 can be The movable one is arranged on the guide rail 13 , a hopper 22 is provided on the top of one end of the base 21 , the base 21 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com