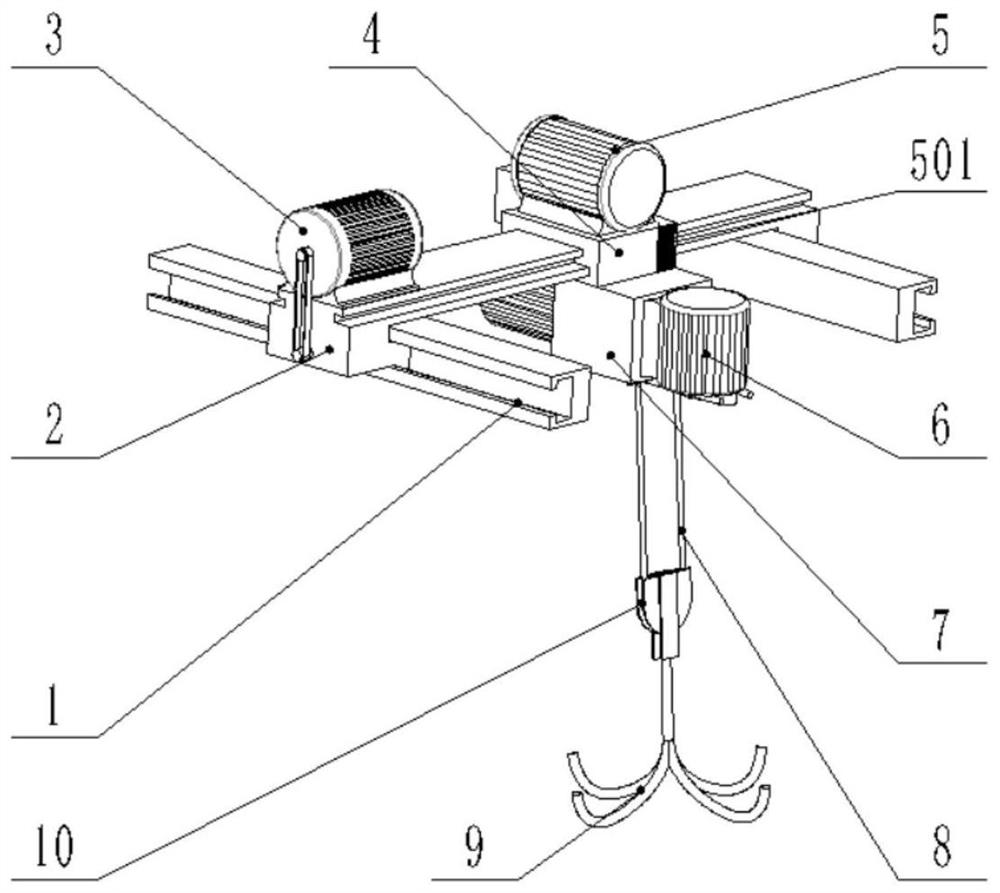

Hanging feeding device and method for powder materials

A feeding device and powder material technology, which is applied in the direction of traveling mechanism, transportation and packaging, loading/unloading, etc., can solve problems such as the impact on workers' health, and achieve the effects of avoiding operational hazards, improving production efficiency, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The powder material hoisting device of the present invention is used for feeding, and the specific process of feeding is as follows:

[0046] S1: Select the appropriate height and position to install the longitudinal rail 1;

[0047]S2: The controller 501 controls the longitudinal movement motor 3 and the lateral movement motor 5 to drive the lateral movement base 4 to move above the material bag;

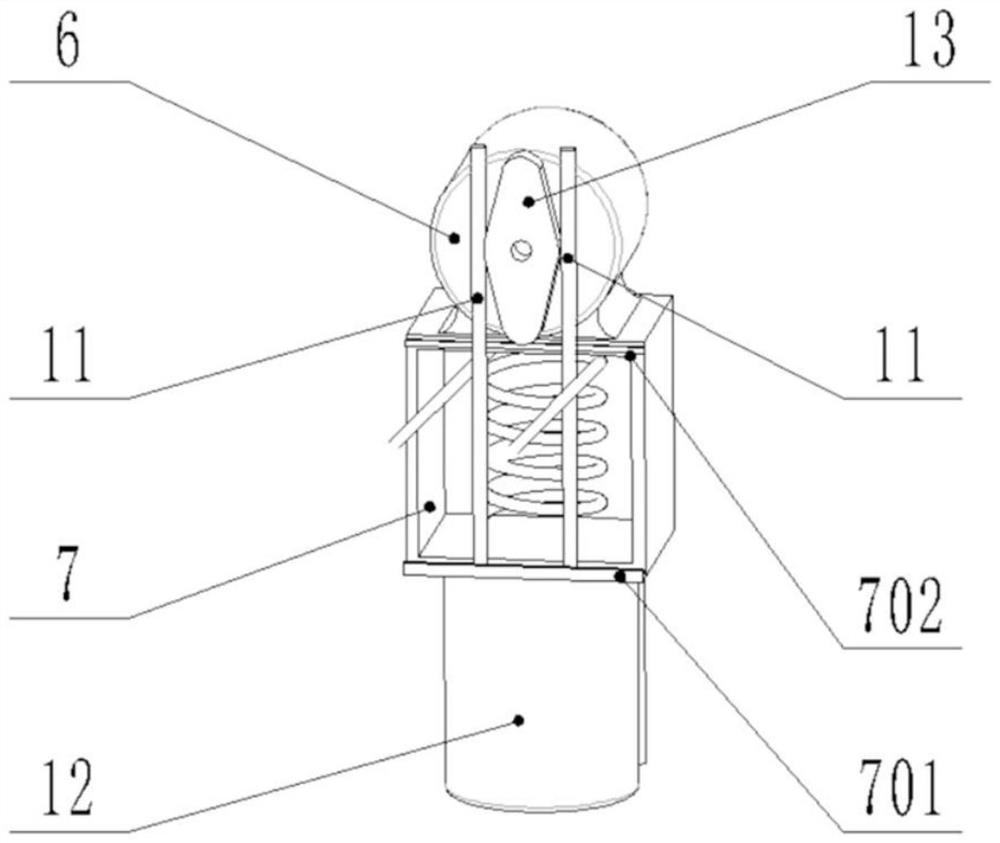

[0048] S3: Control the rotation of the crimping motor 12 by the controller 501 to lower the wire rope 8 to a suitable height, and hang the material bag on the hook 9;

[0049] S4: control the curling motor 12, the longitudinal movement motor 3 and the transverse movement motor 5 through the controller 501 to transport the material bag to the feeding port for feeding;

[0050] S5: The weight sensor collects the gravity value of the material bag in real time and transmits it to the controller 501;

[0051] S6: The controller 501 sets thresholds for starting and stopping the ...

Embodiment 2

[0058] In this embodiment, the cam is set with rounded corners, in order to realize the close contact between the cam and the sliding rod, and improve the stability of the reciprocating motion of the sliding rod. The length ratio between the maximum and minimum cam widths is usually not less than 1.2:1, preferably 2.5:1. The vibration amplitude of the hook can be adjusted by adjusting the length ratio between the maximum and minimum cam widths. The faster the wire rope falls, the greater the vibration amplitude, which is more conducive to overcoming the angle of repose of the material bag.

[0059] In addition, in this embodiment, the cam is arranged in a symmetrical structure, and the hook vibrates up and down once every 180 degrees of rotation of the cam.

[0060] The entire vibration feeding process can be controlled remotely by the controller, and workers do not need to approach the material bag, which avoids dust damage and improves production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com