Synchronous follow current inverter topology without common-mode interference

A common-mode interference and inverter technology, applied in the field of power conversion, can solve the problems of less transformerless inverters, high switching loss, low conversion efficiency, etc., to reduce switching voltage and rated voltage requirements, and reduce freewheeling The effect of low loss and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

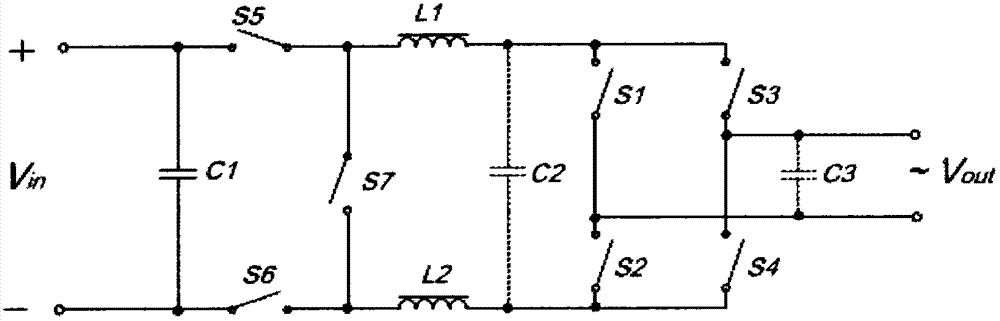

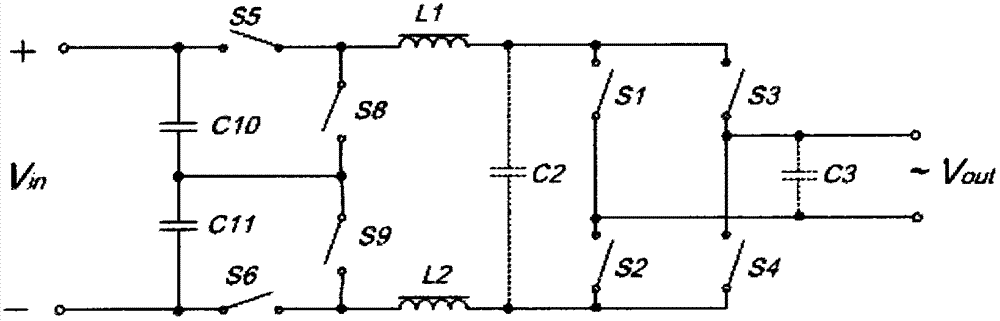

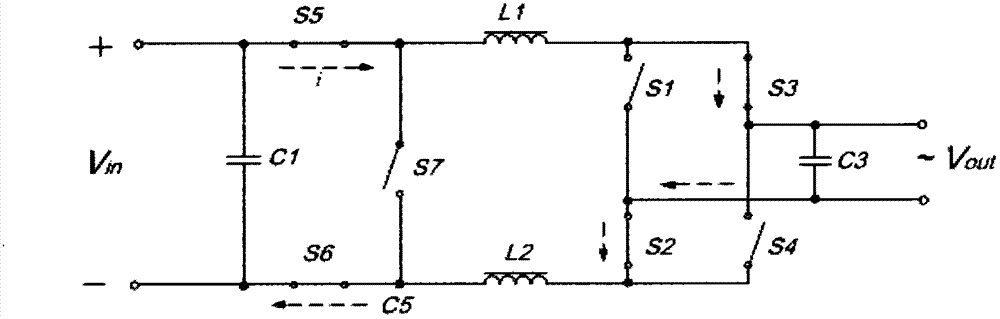

[0018] image 3 , Figure 4 , Figure 5 , Figure 6 is the switch state during operation of the inverter example realized by using the inverter topology of the present invention. image 3 and Figure 4 is the situation when the inverter outputs the AC positive half-wave, Figure 5 and Figure 6 It is the situation when the inverter outputs the negative half-wave of AC. When the inverter outputs the AC positive half-wave, the reversing switches S2 and S3 are kept in the on state; the reversing switches S1 and S4 are kept in the off state, and their blocking voltage is Vout. When the inverter outputs the AC negative half-wave, the reversing switches S1 and S4 are kept in the on state; the reversing switches S2 and S3 are kept in the off state, and their blocking voltage is Vout. The chopper switches S5 and S6 are simultaneously high-frequency switches, and the synchronous freewheeling switch S7 adopts a phase synchronous high-frequency switch opposite to the chopper switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com