Device for separating materials of varying flowability that are mixed together

A separation device and fluidity technology, which is applied in the direction of bone cleaning device, fruit pitting device, application, etc., can solve the problems of fast wear, low yield, low availability of pulp, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The apparatus described in this example was used to separate hard kernels from jujubes. Of course, the device according to the invention can also be used for separating other mixed materials having different flow properties, ie in particular for separating meat, fish and other fruits and vegetables.

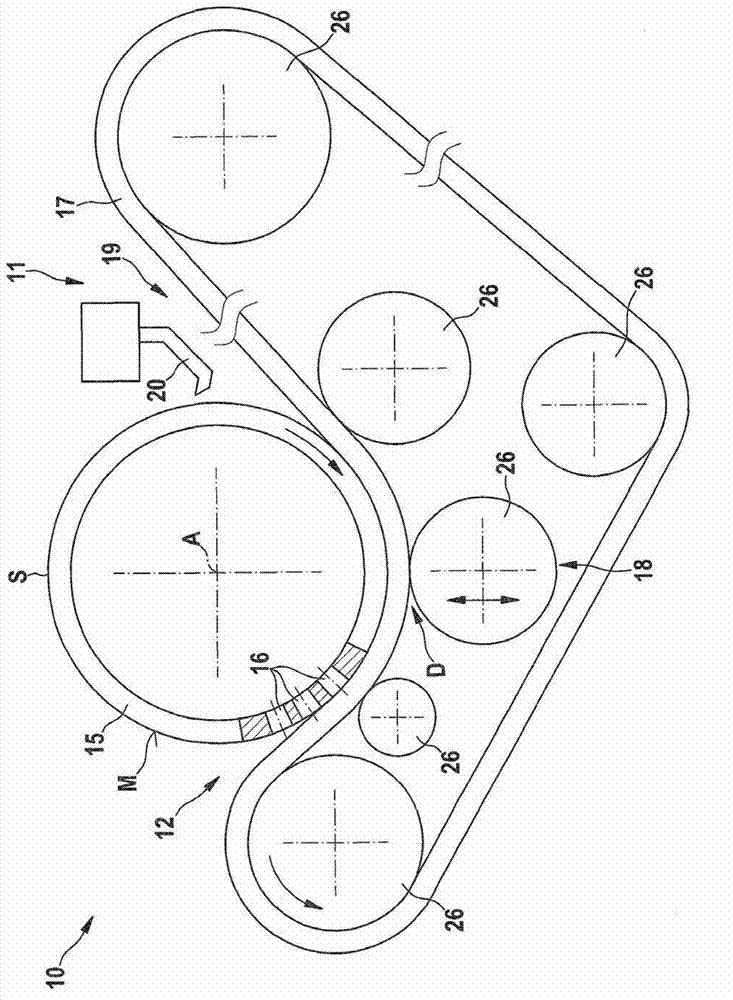

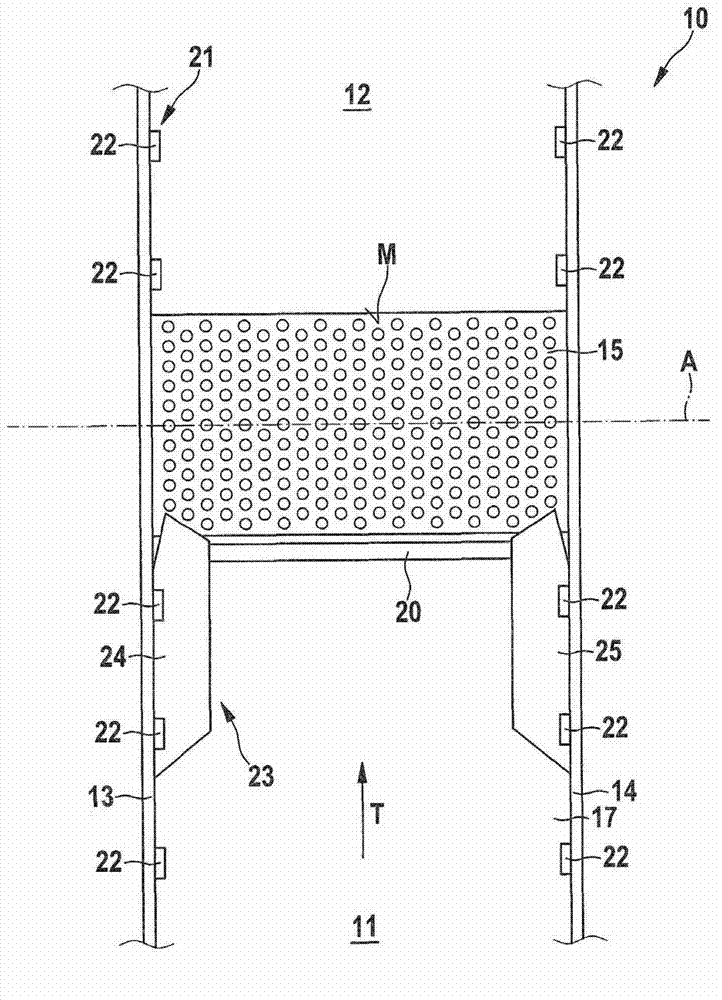

[0020] figure 1 A separating device 10 is shown for separating materials that are mixed together and have different fluidities. The product flow of these mixed materials can be transported in the transport direction T from the product input area 11 to the product output area 12 . The device 10 comprises a body having side walls 13, 14 (only in figure 2 Part of the case shown in ) (not explicitly shown). Between said side walls 13, 14 is mounted a hollow cylinder 15 which can be driven in rotation by a drive mechanism (not explicitly shown). The axis of rotation A of the hollow cylinder 15 is perpendicular to the conveying direction T of the product flow. The hollow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com