Dental abrading agent contaiing spherical resin particles

一种树脂颗粒、制品的技术,应用在牙科、牙科工具、医药科学等方向,能够解决昂贵等问题,达到降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Embodiments of the present invention will be explained below with reference to Examples.

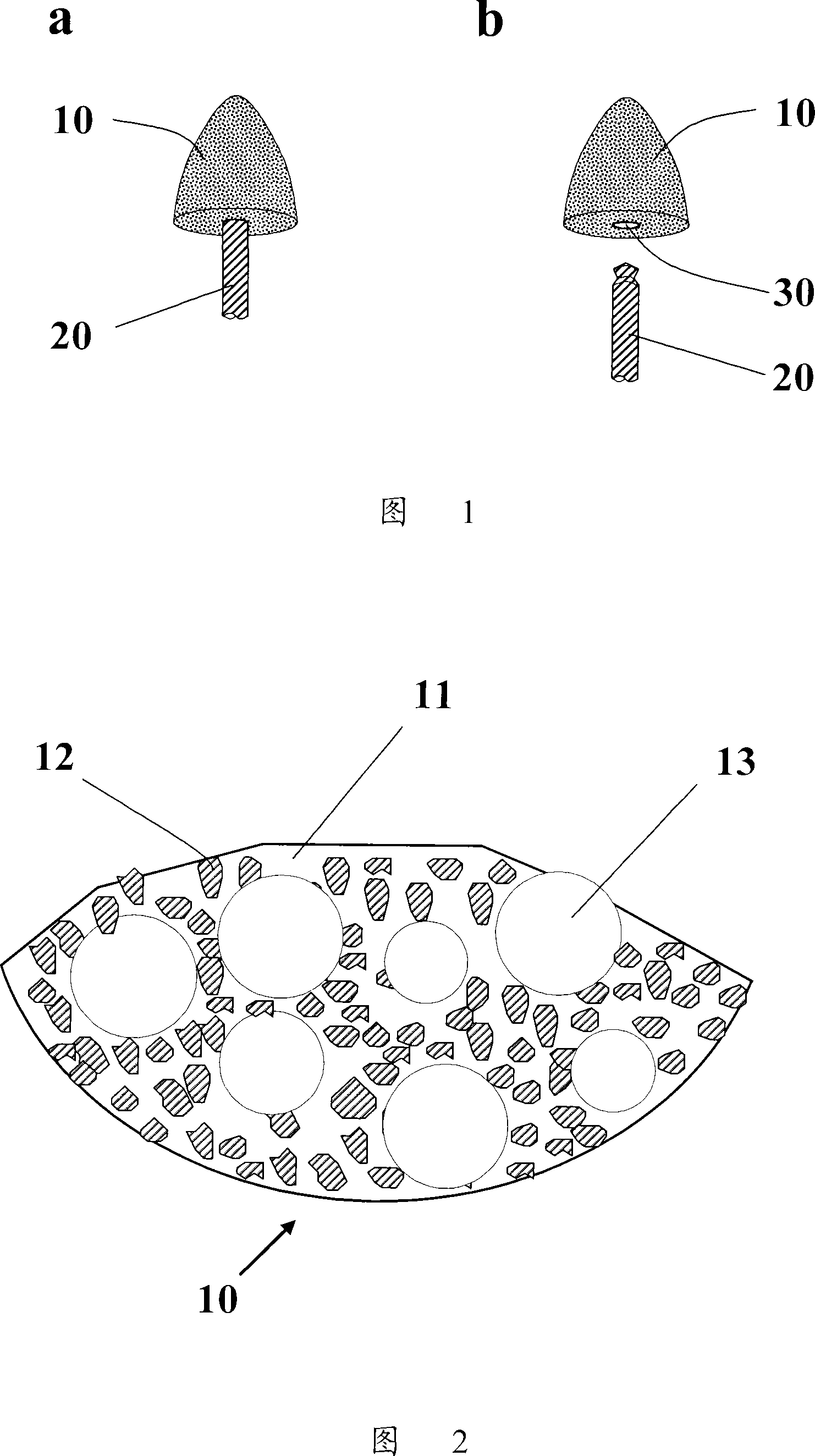

[0057] Polishing materials obtained by mixing the ingredients shown in Table 1 were molded into bullet shapes by hot pressing at 150° C. for 10 minutes to form polishing articles of Examples 1 to 4 and Comparative Examples 1 to 4.

[0058] The evaluation was performed by polishing the surface of the composite resin sample for dental use at 7500 rpm for 30 seconds under a load of about 1 N with each of the polishing articles fixed to a shaft dedicated to a hand piece engine for dental use , to classify machinability (contact during polishing), polishability, and durability based on the following criteria.

[0059] Samples were prepared as follows. First, a stainless steel ring with an inner diameter of 15 mm and a thickness of 2 mm was placed on a glass slide. Dental composite resin (Beautifil Flow, Shofu Inc.) was filled into the ring and another glass slide was placed on top of...

no. 1 approach

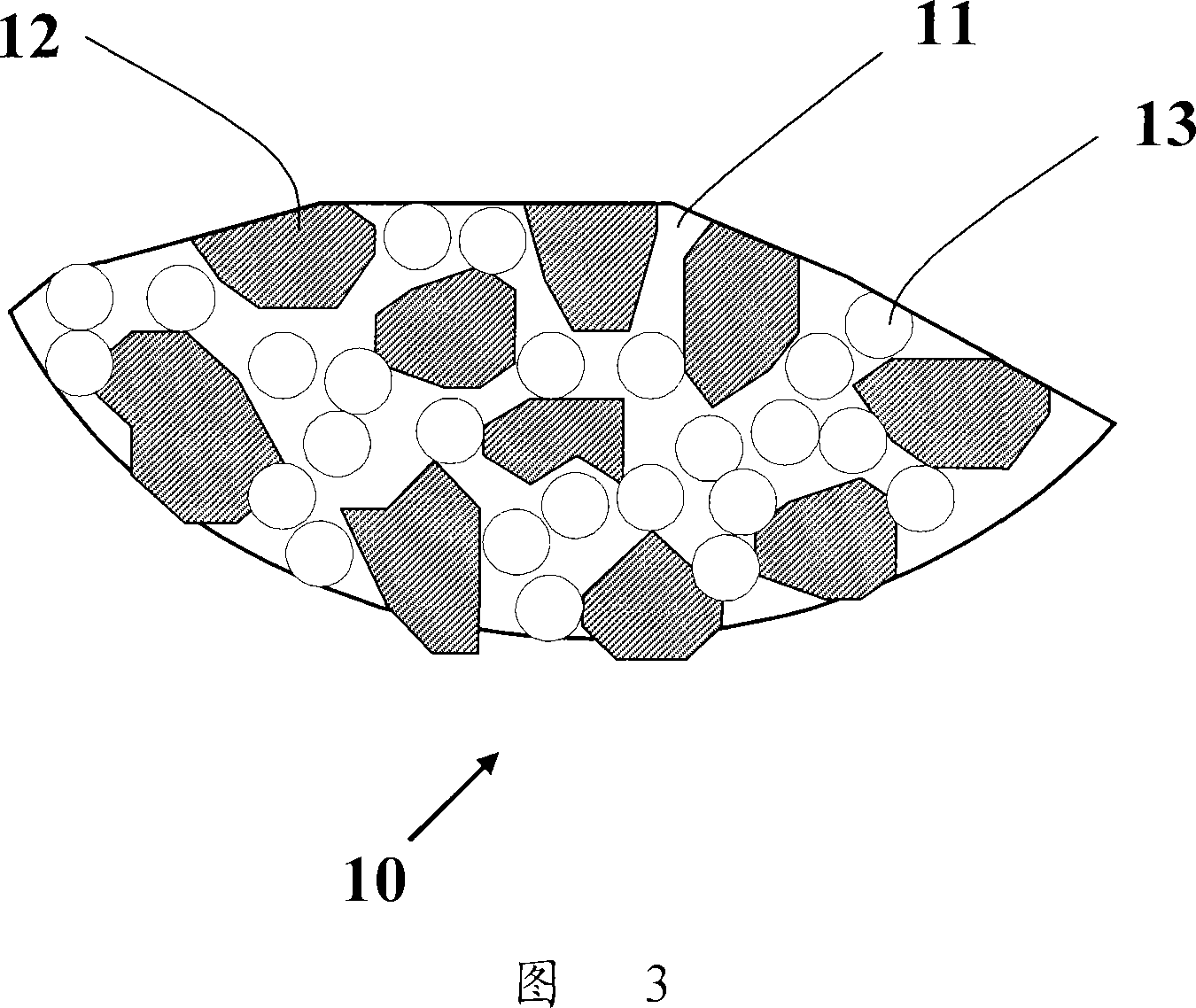

[0103] A cross-sectional view of the polishing section 10 of the first embodiment of the present invention is shown in FIG. 2 . The polishing portion 10 is formed by using a polishing material in which diamond abrasive grains 12 and acrylic resin particles 13 much larger than the diamond abrasive grains are compounded into an elastomer binder 11 .

[0104] Since the acrylic resin particles 13 much larger than the diamond abrasive grains 12 are compounded, high polishability is obtained although the particle diameter of the diamond abrasive grains 12 is small.

Embodiment 1

[0105] Example 1 illustrates a polishing article 1 comprising a polishing portion 10 in which diamonds of 2 to 4 μm are used as polishing abrasive grains 12, and spherical acrylic resin particles having an average particle diameter of 60 μm and 100 μm are compounded into silicon Ketone resin elastomer adhesive 11 (TSE3450, GE Toshiba Silicones Co., Ltd).

[0106] Compared with the polished article of Comparative Example 1 in which spherical acrylic resin particles were not compounded, durability, workability (touch upon polishing), and finish after polishing (glossiness) were improved.

[0107] Example 1 gave a more excellent finished surface than Comparative Example 2 in which many diamond abrasive grains were compounded. Thereby, since so many expensive diamonds are not used, cost can be reduced.

[0108] In Example 1, spherical acrylic resin particles having an average particle diameter of 60 μm and those having an average particle diameter of 100 μm were compounded in a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com