Semiaromatic polyamide and method for producing same

A semi-aromatic and manufacturing method technology, applied in the field of semi-aromatic polyamide, can solve problems such as physical property damage, and achieve the effects of high bending elastic modulus, high heat resistance and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] [Process (i)]

[0105] 1,10-decanediamine (5050 parts by mass) as a diamine component, powdered terephthalic acid (4870 parts by mass) with an average particle diameter of 80 μm, benzoic acid (72 parts by mass) as an end-capping agent, Sodium hypophosphite monohydrate (6 parts by mass) as a polymerization catalyst was put into the autoclave, heated to 100° C., and then stirred with a double-helical stirring blade at a rotation speed of 28 rpm, and heated for 1 hour. The molar ratio of the raw material monomers is 1,10-decanediamine:terephthalic acid=50:50. The mixture was heated to 230° C. while maintaining the rotational speed at 28 rpm, and then heated at 230° C. for 3 hours. The formation reaction and fragmentation of salts and oligomers are carried out simultaneously. After releasing the pressure of the water vapor generated by the reaction, the obtained reactant was taken out.

[0106] [Process (ii)]

[0107] The reactant obtained in step (i) was polymerized by...

Embodiment 2

[0109] [Process (i)]

[0110]A mixture consisting of terephthalic acid powder (4870 parts by mass) with a volume average particle diameter of 80 μm, sodium hypophosphite (6 parts by mass) as a polymerization catalyst, and benzoic acid (72 parts by mass) as an end-capping agent was supplied to the screw. In a bar mixer-type reaction apparatus, under nitrogen-tight conditions, it was heated to 170°C while stirring with a double-helical stirring blade at a rotation speed of 30 rpm. After that, the temperature was kept at 170°C, and the rotation speed was kept at 30rpm. Using a liquid injection device, decanediamine (5050 parts by mass, 100% by mass) heated to 100°C was continuously heated at a rate of 28 parts by mass / min for 3 hours. (continuous injection method) added to terephthalic acid powder to obtain reactants.

[0111] [Process (ii)]

[0112] Then, in the ribbon mixer type reaction device used in the step (i), under the nitrogen flow, the reactant obtained in the step (...

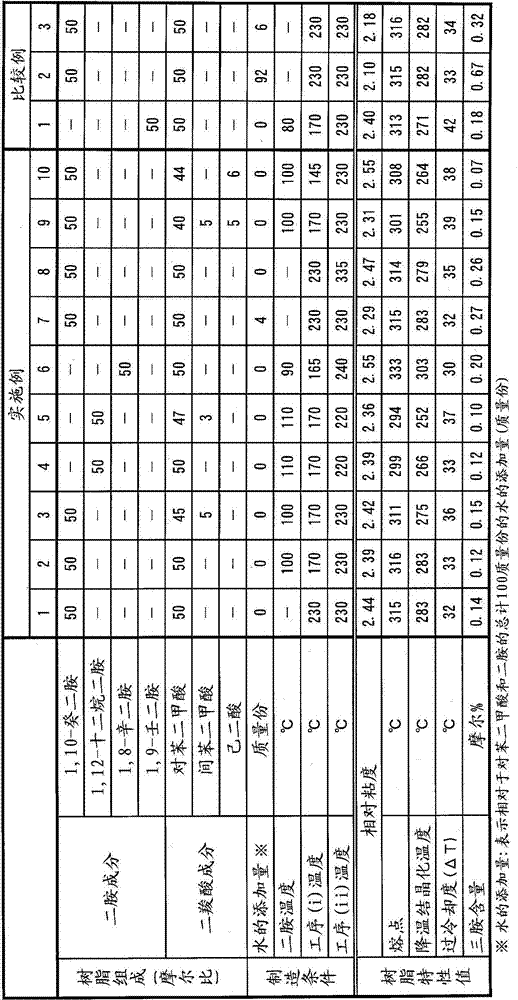

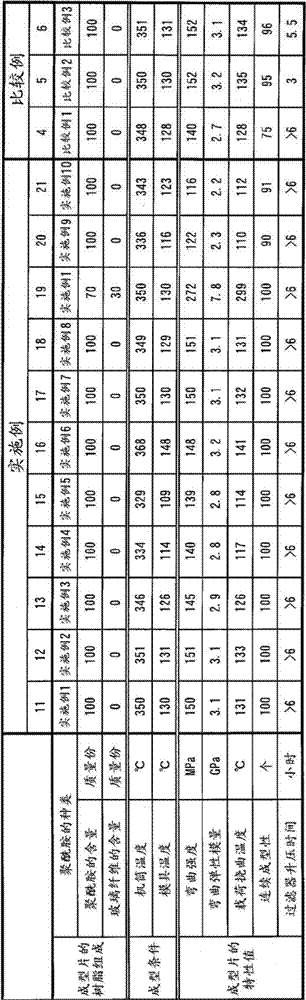

Embodiment 3~6 and 9~10

[0113] Embodiment 3~6 and 9~10, comparative example 1

[0114] Except having changed the kind of the monomer used and manufacturing conditions as shown in Table 1, it carried out similarly to Example 2, obtained the semi-aromatic polyamide, and evaluated it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com