Ore rock breaking hammer

A technology of sledgehammer and arm length, which is applied in grain processing and other fields, and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

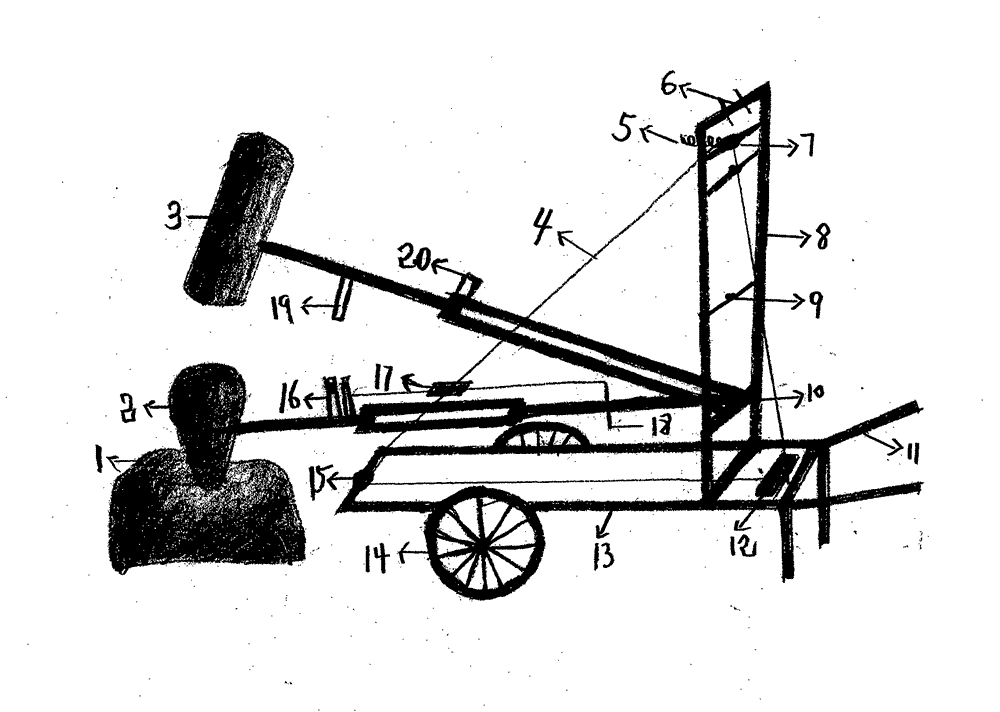

[0020] First introduce the working characteristics of the hoist. The hoist can run forward and reverse. When the power is off, a steel plate will pop up in the moderator of the hoist, so that the hoist cannot rotate forward or reverse when the power is off. The winch can hang the lifted items in mid-air like this.

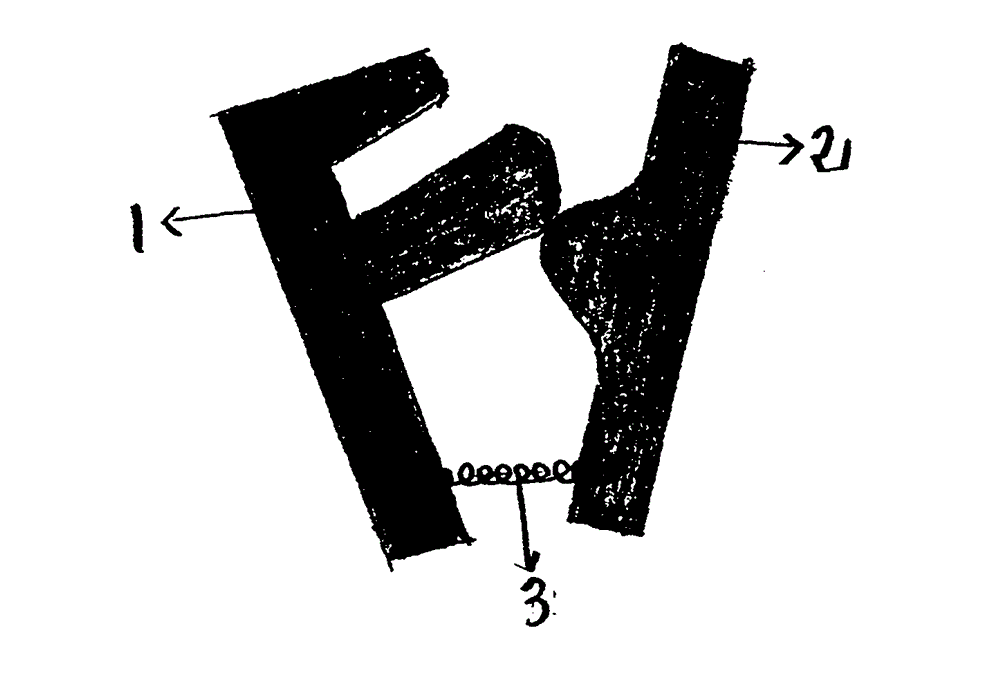

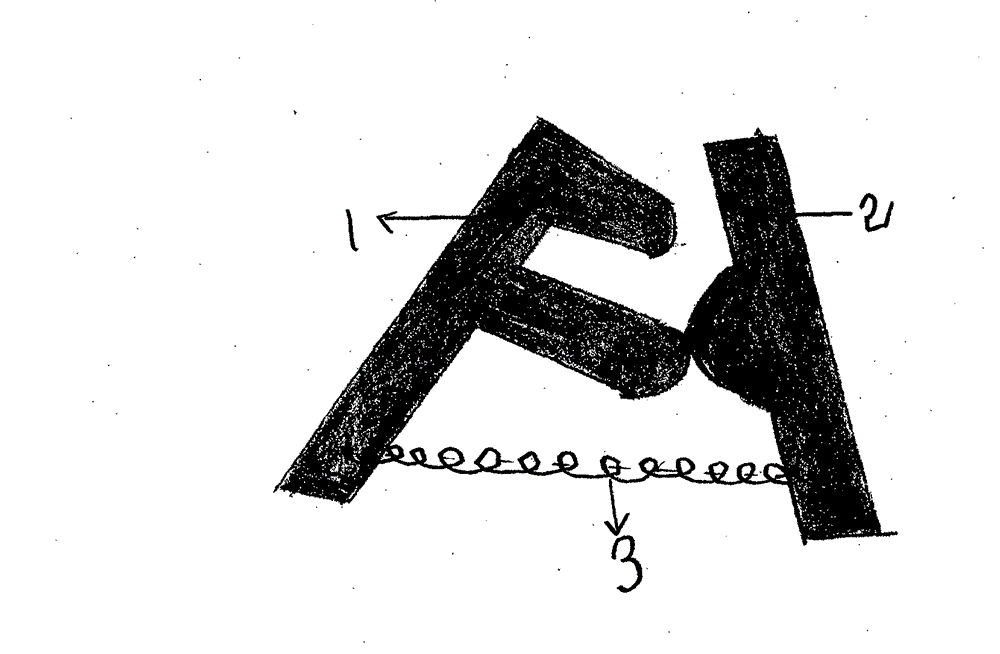

[0021] When the rock hammer is working, the upper hammer falls and merges with the lower hammer, the U-row steel bars under the upper hammer coincide with the U-row steel bars above the lower hammer, and the upper latch is manually pushed to make the upper hammer and lower hammer integrated. Turn the winch forward, the wire rope goes up, the fixed iron plate on the wire rope will bring up the upper hammer and the lower hammer, cut off the power supply, and aim the lower hammer at the stone to be broken. Reverse the winch, make the lower hammer fall on the stone, disconnect the power supply, and manually pull out the latch. When the hoist is turned forward, the u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap