Short strip automatic leveling feeder

An automatic and horizontal feeding technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of affecting product quality, easy to produce errors, and many mechanical structures, so as to achieve simple structure, high production efficiency and less mechanical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

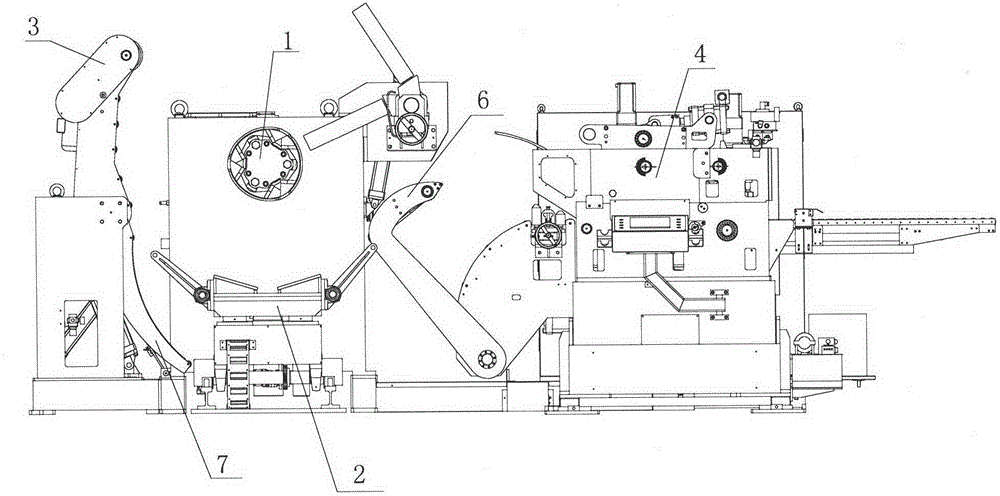

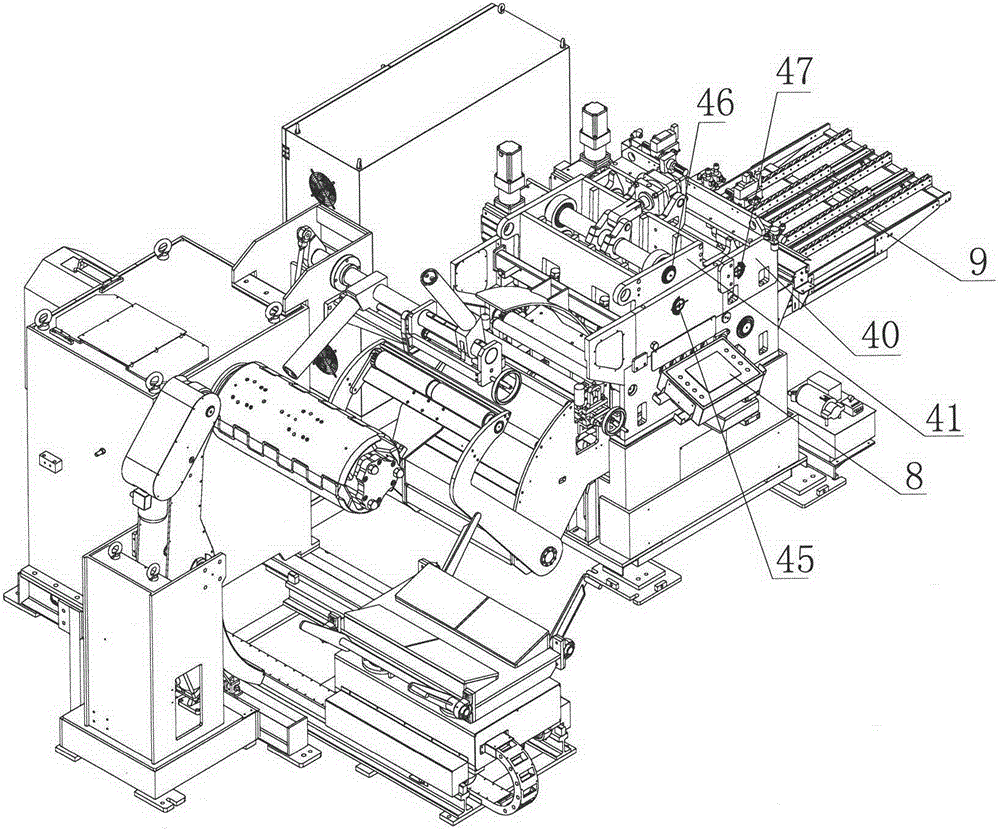

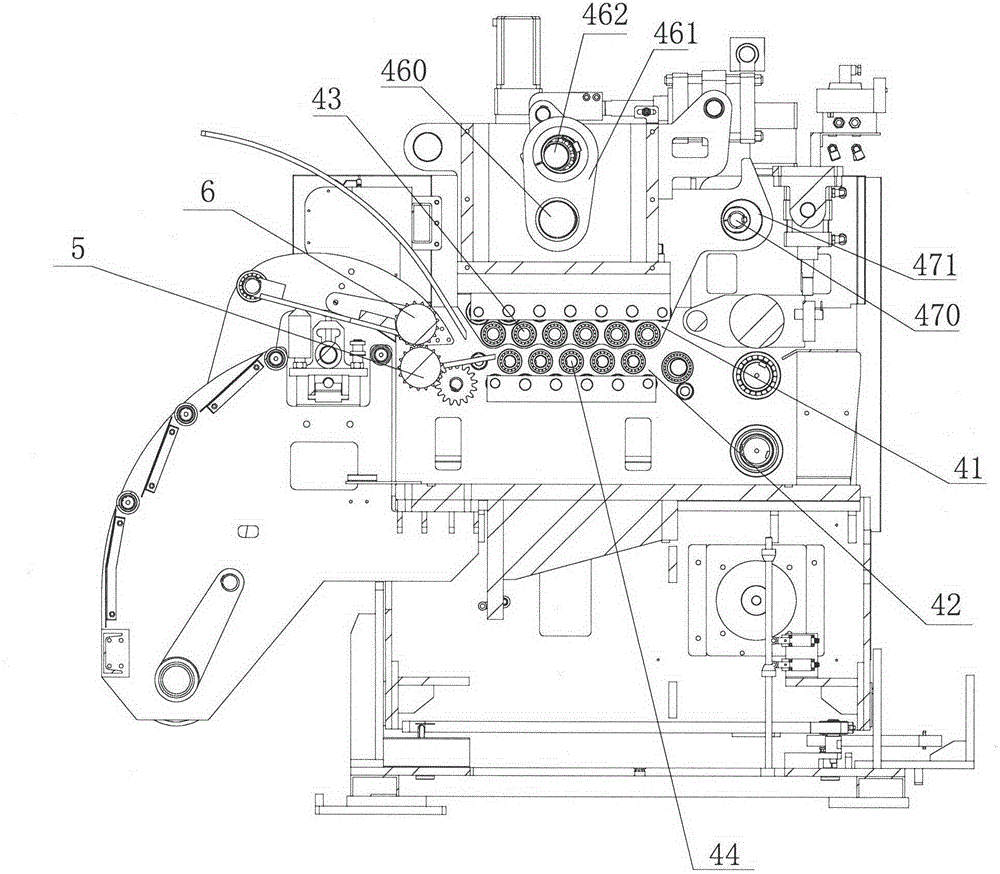

[0016] In this example, refer to Figure 1 to Figure 3 As shown, the automatic leveling and feeding machine for short-length materials includes an uncoiling device 1, a charging device 2 arranged on the side of the uncoiling device 1, and a pressing device 3 arranged at one end of the uncoiling device 1, and is arranged on the other side of the uncoiling device 1. A leveling device 4 at one end, and a positioning device 10 arranged between the uncoiling device 1 and the leveling device 4; the front end of the leveling device 4 is provided with a positioning roller 5, and a pressing material is arranged above the positioning roller 5 Head device 6; the leveling device 4 includes a shell 40, and an upper wheel base 41 arranged in the shell 40, and a lower wheel base 42 opposite to the upper wheel base 41, and the upper wheel base 41 is provided with an upper roller The wheel set 43, the lower wheel set 42 is provided with the lower roll set 44 opposite to the upper roll set 43, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com