Heavy-load railway pre-cast T beam overall binding carcass and construction method thereof

A construction method and overall technology, applied in the field of heavy-duty railway prefabricated T-beam integral binding mold and its construction, can solve the problems that it is difficult to meet the requirements of beam body steel structure integrity and positioning accuracy, increase the occupation time, etc. To achieve the effect of ensuring integrity, saving time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

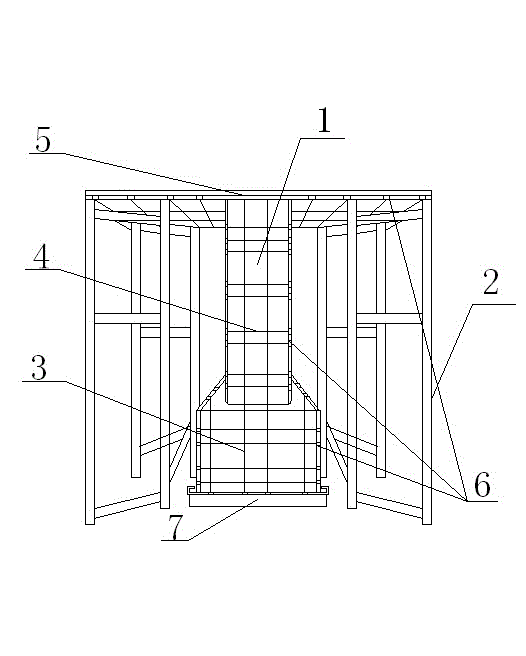

[0027] Embodiment: The overall binding mold of the present invention is 10 cm higher than the bottom surface, and the inner tire frame 1 and the bottom surface are connected as a whole through embedded parts, and the operation is performed directly on the ground. The outer tire frame 2 of the present invention is composed of symmetrically arranged guardrails , the height of the guardrail is adjustable, and the inner tube frame 1 is symmetrically arranged on the left and right. When installing, it is precisely positioned in strict accordance with the position of the semicircular notch 6, and the position of the semicircular notch 6 of the present invention is fixed. ×5mm angle steel, the embedded part is fixed with L80×10mm angle steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com