Plate extrusion addition type width adjustment apparatus

A technology of width adjustment and sheet material, which is applied in the field of extruded sheet external width adjustment device, which can solve the problems of labor and material waste, excess leftover material, and increased energy consumption, and achieves low price, adjustable width, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

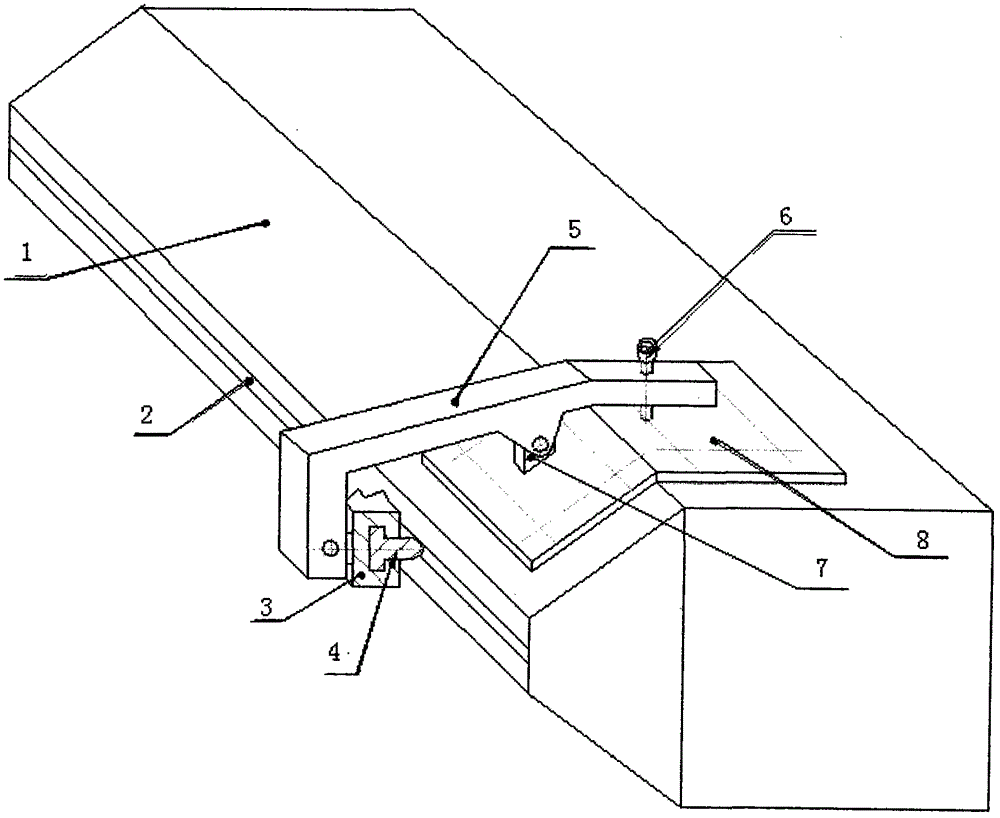

[0010] Further illustrate structure of the present invention in conjunction with accompanying drawing

[0011] Such as figure 1 The extruded plate width adjustment device mainly includes: tongue depressor 4, tongue depressor seat 3, movable rocker arm 5, jacking bolt 6, support 7, fixing part 8, auxiliary parts, which are used in extrusion The mold 1 is equipped with a fixing piece, and one end of the movable rocker arm is respectively fixed on the fixing piece through a supporting piece and a tightening bolt, and the other end of the movable rocker arm is connected to a tongue depressor seat, and a tongue depressor is inserted into the tongue depressor seat, and the tongue depressor is inserted into the extrusion Out of the mold outlet 2. The tongue depressor is composed of a tongue body and a base. The tongue body adopts an arc design, and the tongue body and the base are integrated into a T-shaped structure. Among them, the tongue depressor adopts a split-point compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com