Air compressor device for glue supplement and air inflation

An air compressor and glue filling technology, which is applied in transportation and packaging, vehicle maintenance, vehicle maintenance/repair, etc., can solve problems such as time-consuming operation, stickiness, and troublesome rescue operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific embodiments.

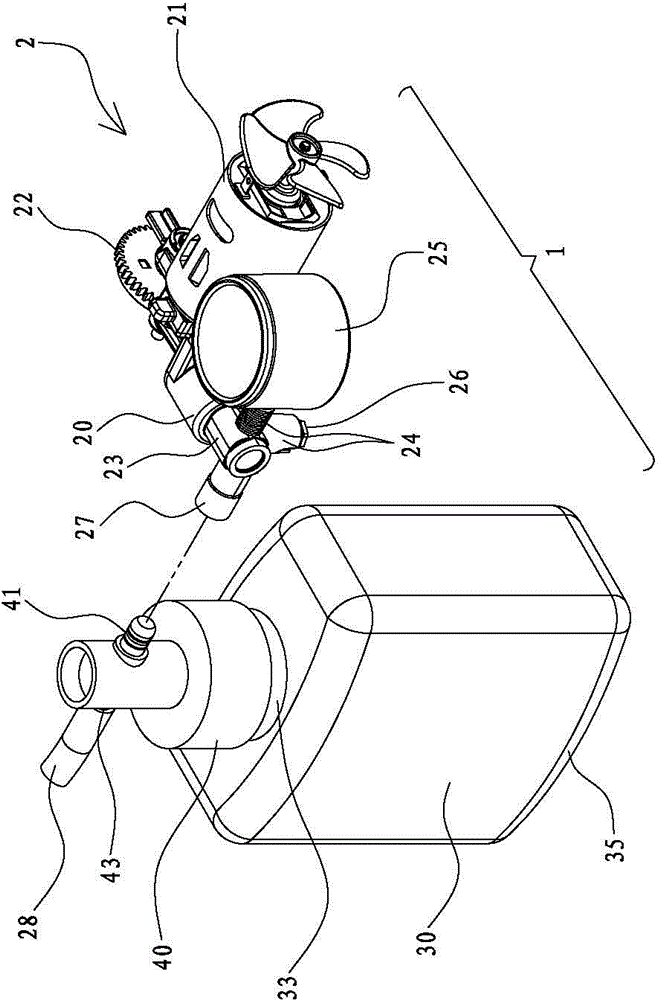

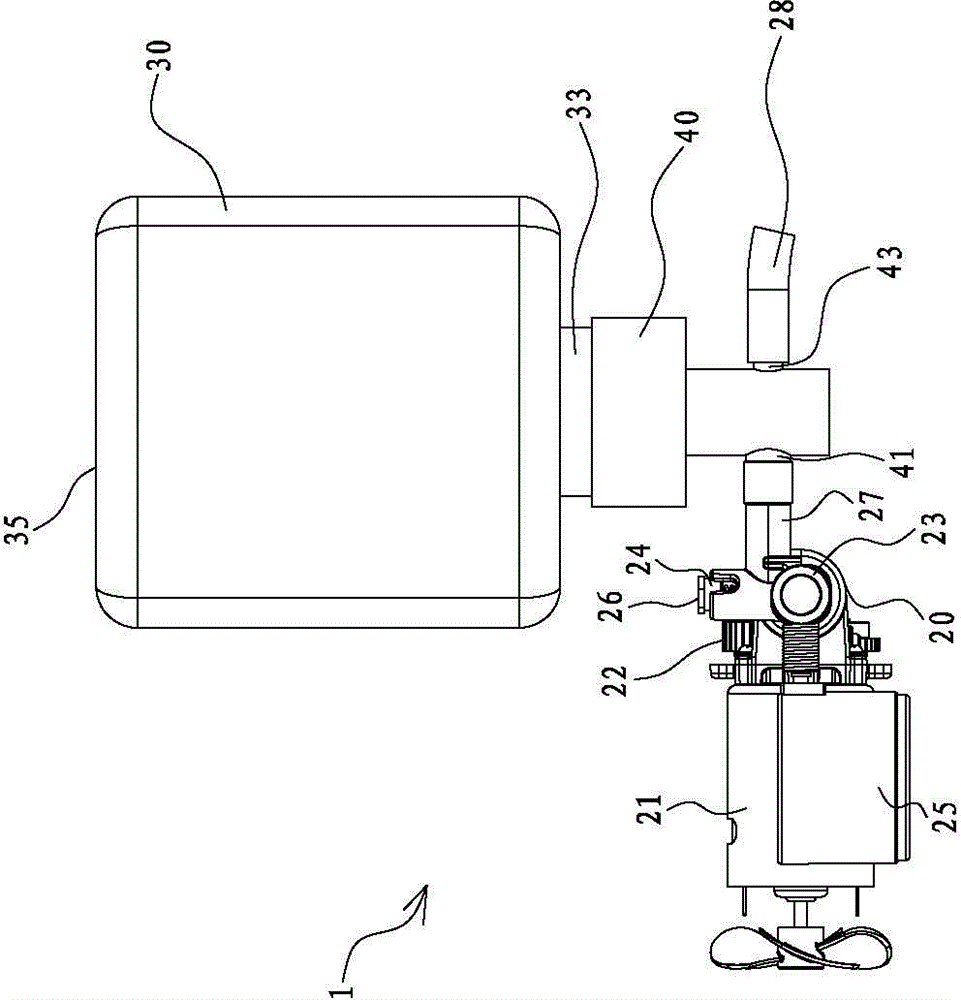

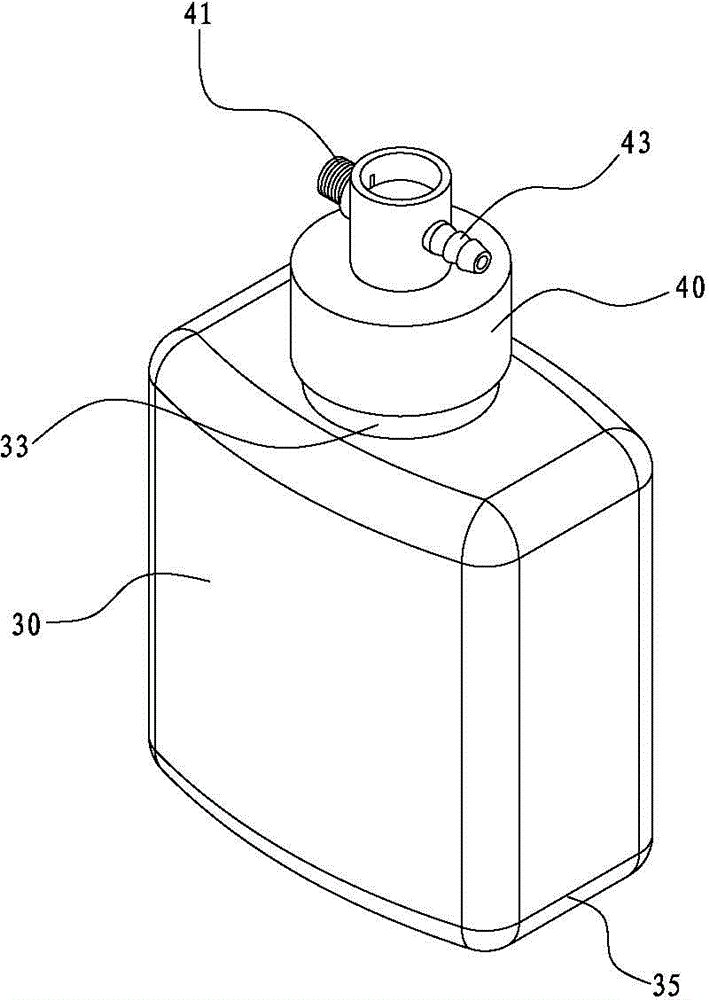

[0050] Please refer first figure 1 , figure 2 , image 3 and Figure 5 The air compressor device 1 for replenishing and charging in the present invention includes an air compressor 2, a replenishing tank 30, and a cover 40. The air compressor 2 has a cylinder chamber 20 in which a piston body (not shown in the figure) can be accommodated. A motor 21 can actuate the gear 22 and drive the piston body to reciprocate up and down in the cylinder chamber 20. The compressed air can be sent out through the air outlet manifold 27 of the air storage seat 23, and other manifolds 24 can be provided on the air storage seat 23. The pressure gauge 25, the safety valve 26, and the above air compressor structure can be connected to the manifold 24 It is a typical structure, so it will not be described in further detail.

[0051...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com