Novel top cover decoration strip mounting structure

A technology for installing structures and decorative strips, applied in the directions of transportation, packaging, vehicle parts, etc., can solve the problems of high cost, easy loosening, and inconspicuous decorative effects, and achieve the effects of saving development costs, good decorative effects, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

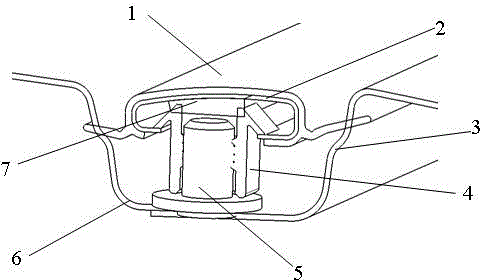

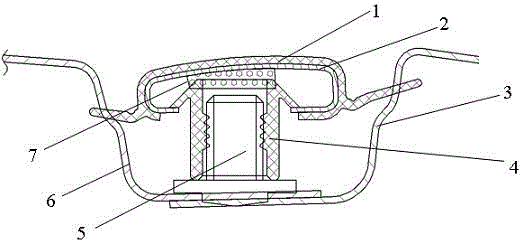

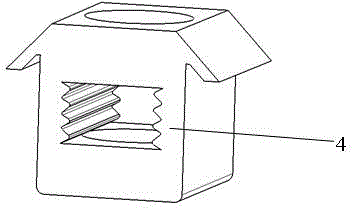

[0017] Such as Figure 1-4 As shown, a new roof trim installation structure described in the embodiment of the present invention includes at least one bolt connector 5, a barb buckle 4, a roof trim sheet metal inner frame 2 and a roof trim The body 1 and a foam pad 7, the barb buckle 4 is fixedly connected with the top cover decorative strip sheet metal skeleton 2 through barbs, the thread of the bolt connector 5 is fixedly connected with the barb of the barb buckle 4, and the bolt connection Part 5 is welded and fixed on the roof welding edge 3 of the automobile body 6.

[0018] The barb buckle 4 restricts the movement of the barb buckle 4 in the radial direction of the bolt through the action of the barb and the thread of the bolt connector 5, and the barb buckle 4 passes through the undercut of the top cover decorative strip sheet metal inner frame 2 and the top The cover decorative strip body 1 is fixed.

[0019] The beneficial effects of the present invention are specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com